A Simple Clutch

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

for Light Vehicles A New Borg and Beck Product of Ingenious Design and Easy of Application -nOSSIBpY no concern has had more experience in connection with the manufacture of clutches than the American Borg and Beek Co., of Chicago. Their models are handled in this country by Automotive Products, Ltd., 3,

Berners Street, London, W.1. In the near future, as already announced in these pages. the company will more to Brock House, Great Portland Street, London, W.1.

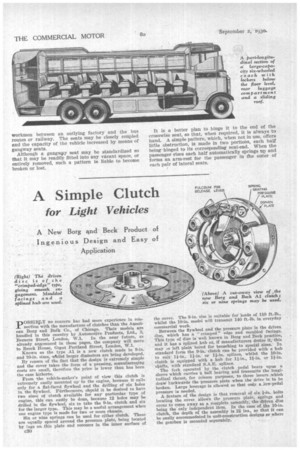

Known as the type Al is a new clutch made in 9-in. and 10-in. sizes, Whilst larger diameters are being developed.

By reason of the fact that the design is extremely simple and the cover takes the form of a pressing, manufactiging costs are small, therefore the price is lower than has been the ease hitherto.

From the vehicle-maker's point of view this clutch is extremely easily mounted up' to the engine, because it calls only for a flat-faced flywheel and the drilling of six holes in the flywheel. Furthermore, should it be desired to have two sizes of clutch available for any particular type of engine, this can easily be done, because 12 holes may be drilled in the fly-wheel, six to take the 9-in, clutch and six for the larger type. This may be a useful arrangement when One engine type is made for two or more chassis.

Six or nine springs can be used for either clutch. These are equally spaced around the pressure plate, being located by lugs on this plate and recesses in the inner surface of c30 the cover. The 9-in, size is suitable for loads of 110 ft.-lb., whilst the 10-in, model will transmit 140 ft-lb. in everyday commercial work.

Between the flywheel and the pressure plate is the driven disc, which has a " crimped " edge and moulded facings. This type of disc is well known in Borg and Beck practice, and it has a splined hub or, if manufacturers desire it, this may Je left plain bored for broaching to special sizes. In standard form the 9-in, clutch can he provided with a hub

to suit 11-in. or 1g-in. splines, whilst the 10-in. clutch is equipped with a hub for 11-in., 1g-in. or 14-in. shafts, with standard S.A.E. splines.

The fork operated by the clutch .pedal bears ripen a sleeve which carries a ball bearing and transmits the longitudinal thrust, for release purposes, to three levers which draw lackwards the pressure plate when the drive is to be broken. Large leverage is allowed so that only a low-pedal pressure is needed. A feature of the design is that removal of six g-in. bolts locating the cover allows the pressure plate, springs and cover to come away as a complete assembly, the driven disc being the only independent item. In the case of the 10-in. clutch, the depth of the assembly is 2g ins., so that it can be easily accommodated in unit-construction designs or where the gearbox is mounted separately.