HINTS ON MAINTENANCE.

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

558.--Improving the Radius Road Anchorage of the Rover Van.

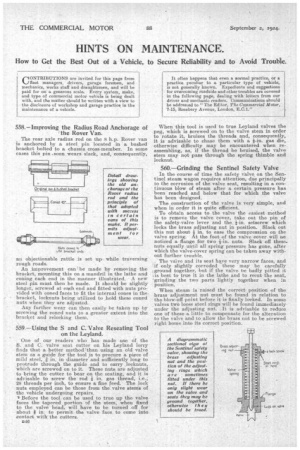

The rear axle radius rod on the 8 h.p. Rover van is anchored by a steel pin located in a bushed bracket bolted to a chassis cross-member. In some eases this pin ‘soon wears• slack, and, consequently,

an objectionable rattle is set up while traversing rough roads.

An improvement can be made by removing the bracket, mounting this on a mandril in the lathe and coning each end in the manner illustrated. A new steel pin must then be made. it should be slightly longer, screwed at each end and fitted with nuts provided with coned faces to fit the internal cones in the bracket, locknuts being utilized to hold these coned nuts when they are adjusted.

Any further wear can then easily be taken up by screwing the coned nuts to a greater extent into the bracket and relockingthem.

559.—Using the S and C. Valve Reseating Tool on the Leyland.

One of our readers who has made use of the S. and C. valve seat cutter on his Leyland lorry finds that a better method'than using an old valve stem as a guide for the tool is to procure a piece of mild steel, -g in. in diameter and sufficiently long to protrude through the guide and to carry .locknuts, which are screwed on to it. These nuts are adjusted to bring the cutter to bear on the seating, and it is

advisable to screw the rod in. gas thread, i.e.; 28 threads per inch, to ensure a fine feed. The lock nuts employed can be those from the. valve stems of the vehicle undergoing repairs.

%Before the tool can be used to true up the valve faces the tapered portion of the stem, when fixed to the valve head, will have to be turned off for about I in. to permit the valve face to come into contact. with the cutters.

n46 When this tool is used to true Leyland valves the peg, which is screwed on to the valve stem in order to rotate it, bruises the threads and, consequently, it is advisable to chase them with a i-in. gas die, otherwise difficulty may be encountered when reassembling, as, if the thread be bruised, the valve stem may not pass through the spring thimble and locknut.

5611—Grinding the Sentinel Safety Valve

In the course of time the safety: valve on the Sentinel steam wagon requires attention, due principally to the corrosion of the valve seat, resulting in a continuous blow of steam after a certain pressure has been reached and below that for which the valve has been designed.

The construction of the valve is very simple, and when in order it is quite efficient.

To obtain access to the valve the easiest .method is to remove the valve cover, take out the pin of the safety-valve lever and the *-in. setscrew which locks the brass adjusting nut in position. Slack out this nut about in. to ease the compression on the valve spring. At the foot of the valve cover will oe noticed a flange for two i-in. nuts. Slack off these. nuts equally until all spring pressure has gone, after which the valve-cover spring' can be taken away without further trouble.

, The valve and its seat have very narrow faces.; and if only slightly corroded these may be carefully ;ground together, but if the valve be badly pitted it is best to true it in the lathe and to recut the seat, 'grinding the two parts lightly together when in position.

When steam is raised the correct position of the brass adjustment nut must be found in relation to the blow-off point before it is finally locked. In some _valves two loose steel rings will he found immediately under the adjusting nut. It is advisable to reduce one of these a little to compensate for the alteration to the valve and to allow the brass nut to be screwed right home into its correct position.