An honourable dischargi

Page 22

Page 23

Page 24

If you've noticed an error in this article please click here to report it so we can fix it.

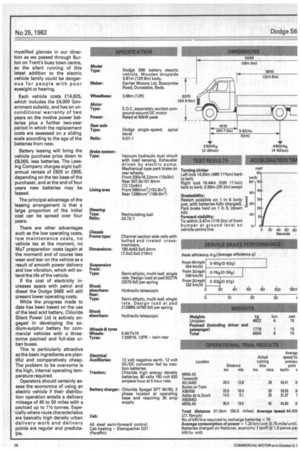

The Dodge 50-Series S66E electric vehicli acquitted itself well over our 91km route and its operating costs were a third of a comparable diesel-engined vehicle. Bryai Jarvis reports on this urban deliverer

ELECTRIC vehicles have been around for several years in various forms. They can be seen at mainline railway stations, in workshops and warehouses, and as invalid carriages and milk floats. One of them has even explored the moon's surface.

However, the Dodge 50-Series S66E electric vehicle is a cut above the present terrestrial vehicles. It is a conventional 50 Series in all but power source, transmission, cab heater and controls. The cab is comfortable and well heated by the Eberspacher D3L paraffin heater, which takes several minutes to warm up and cool down.

It does have different operating characteristics and once the driver has come to terms with them, it becomes a nippy, silent (almost too silent) urban delivery vehicle.

It has the obvious ecological advantages of being quiet and pollution-free as well as having economical operating costs, much lower maintenance charges and a performance which is compatible with normal, urban traffic flow.

The vehicle dealt very capably with CM's route of 91km (56.9 miles) which encompassed very mixed terrain.

Its acceleration was surprisingly quick, reaching 32km/h (20mph) in 9 seconds, 48km/h (30mph) in 21 seconds and 64km/h (40mph) in just under 60 seconds.

It kept pace with traffic, in and und Tamworth, Burton on nt and never dropped below m/h (25mph) while gliding the A50 towards Newhall, n coping with the short 1 in jradient at Winshill.

he vehicle tested had exces? brake pedal travel and a ht sponginess, but for all that efficiency was quite acceptain the dry conditions encountd on the test.

arrier has carried out modifions to the 80 vehicles of this a already in service; it has uced the brake control rod fel and altered the brake mascylinder ports, which has imwed brake performance, :ording to Karrier Motors tric vehicle specialist David in.

he vehicle handled very well around the twisting parts of the route, although there was a slight negative steer either side of centre. It carried a full, evenly distributed payload of 1.78 tonnes (1.75 tons) which brought the overall weight up to its plated gvw of 6.6 tonnes (6.5 tons).

Outwardly the Dodge 566 looks little different from its diesel-engined counterpart except for the low-slung mass of its traction batteries carried evenly on each side of the chassis, which gives the vehicle a considerably lower centre of gravity.

A total of eighty batteries form the 160 volt, 420 ampere per hour, high energy density, lead acid unit which has a total weight of two tonnes (1.9 ton).

The batteries are housed in six separate, rubber lined steel trays and fitted with the Chloride' Autofill automatic filling system which allows for topping up both sides in less than 20 minutes.

Located at the rear of the chassis is the control point for the system, which has no-leak connectors. The system's single breather is located outside the rear of the cab on the passenger's side.

Supplied with each vehicle is a Chloride Spegel SP 80/80 fully automatic charging unit which is so programmed that is is impossible to overcharge the batteries. This is connected quickly and safely to the vehicle for overnight charging via the jack plug located under the bonnet on the left hand bulkhead.

It will recharge the fully discharged batteries in eight hours and when the charger is being disconnected from the vehicle electronic circuitry prevents arcing occurring. By the time our vehicle had covered 80km (50 miles) the needle on the battery condition gauge, which is mounted on the fascia, had reached the red sector and a red light in the top of the gauge blinked its warning that the batteries were down to the last 10 per cent of capacity.

From that point, power seemed to fall off at gradients until the last of the 91km by when I was constantly looking for a safe place to park and await the towing vehicle.

One effect of battery power is that when seemingly exhausted, batteries do in fact recover a small amount of power after standing for an hour, and as a result can move a short distance.

The 91km (56.9 miles) covered required 7 6kw/h units of electricity, which cost 1.9 pence per unit on the national economy 7 tarriff. This equates to an overall fuel cost of £1.44 for the journey or 1.59 pence per km (2.54 pence per mile).

A similar type of vehicle with petrol or diesel engine could not be expected to complete the same journey for the same fuel cost or in a faster time. Our average speed over the 91km was 44.4km/hr or 27.76mph.

Commercial Motor's current Tables of Operating Costs show a fuel cost per mile for a dieselengined vehicle with a comparable payload (30 cwt.) as being 6.00p.

Compared to the earlier electric vehicles built by Dodge, the control system has been totally redesigned with transistorised circuits for improved reliability and reduced size and weight.

The controller is a Chloride Legge electronic type, which also provides regenerative braking from the electric motor and fits neatly beneath the former engine's cowl. It is quieter and smoother than earlier thyristor controllers and is accessible for servicing from inside or outside the cab, or can be removed by one person quite easily.

Operating the vehicle is very similar to one with an automatic gearbox, as the selector offers forward, neutral or reverse.

During journeys the controller, operated by a conventional accelerator pedal, makes very little noise at all except for a whirring sound during braking when the initial brake pedal movement brings in the limited, regenerative braking effect.

When the electrically driven exhauster replenishes the brake vacuum reservoir, it gives off a buzzing noise which seems louder than normal because of the otherwise near-silent running.

The drive motor is the EDC separately excited, compoundwound DC motor rated at 50kW. It is of frameless construction and claimed by Karrier to be 90kg lighter and 40 per cent cheaper than its predecessor in the Silent Karrier.

Karrier Motors claims a speed range of up to 64km/h (40mph) but the vehicle tested reached 80km/h (50mph) and was extremely quiet, registering a maximum in-cab level of 68dB on the noise meter. At 48km/h (30mph) the noise reached 57dB, and the direction indicator raised this by 4dB.

Several pedestians directed mystified glances in our direction as we passed through Burton on Trent's busy town centre, so the silent running of this latest addition to the electric vehicle family could be dangerous for people with poor eyesight or hearing.

Each vehicle costs £14,625, which includes the £4,000 Government subsidy, and has an unconditional warranty of two years on the motive power batteries plus a further two-year period in which the replacement costs are assessed on a sliding scale according to the age of the batteries from new.

Battery leasing will bring the vehicle purchase price down to £8,000, less batteries. The Leasing Company charges eight halfannual rentals of £825 or £905, depending on the tax base of the purchaser, and at the end of four years new batteries may be leased.

The principal advantage of the leasing arrangement is that a large proportion of the initial cost can be spread over four years.

There are other advantages such as the low operating costs, low maintenance costs, no vehicle tax at the moment, no MoT preparation costs (again at the moment) and of course less wear and tear on the vehicle as a result of smooth power delivery and low vibration, which will extend the life of the vehicle.

If the cost of electricity increases apace with petrol and diesel the Dodge S66E will still present lower operating costs.

While the progress made to date has been based on the use of the lead acid battery, Chloride Silent Power Ltd is actively engaged in developing the sodium-sulphur battery for commercial vehicles with a threetonne payload and full-size urban buses.

This is particularly attractive as the basic ingredients are plentiful and comparatively cheap. The problem to be overcome is the high, internal operating temperature required.

Operators should certainly assess the economics of using an electric vehicle if their distribution operation entails a delivery mileage of 45 to 50 miles with a payload up to 11/2 tonnes. Especially where route characteristics are basically high density urban delivery work and delivery points are regular and predictable.