Wire Mesh for Poultry Carrier

Page 75

If you've noticed an error in this article please click here to report it so we can fix it.

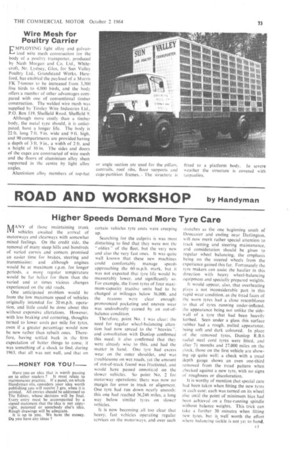

EMPLOY1NG light alloy and galvanized wire mesh construction for the body of a poultry transporter, produced by Nash Morgan and Co. Ltd., Whitecroft, Nr, Lydney, Clos, for Sun Valley Poultry Ltd., Grandstand WOrks, Hereford, has enabled the payload of a Morris FK 7-tonner to be increased from 3,300 live birds to 4.000 birds, and the body offers a number of other advantages compared with one of conventional timber construction. The welded wire mesh was supplied by Tinsley Wire Industries Ltd., P.O. Box 119, Sheffield Road, Sheffield 9. Although more costly than a timber body, the metal type should, it is anticipated, have a longer life. The body is 22 ft. long 7 ft. 9 in. wide and 9 ft. high, and 90 compartments are provided having a depth of 3 ft. 9 in., a width of 2 ft. and a height of 10 in. The sides and doors of the cages are constructed of wire mesh and the floors of aluminium alloy sheet supported in the centre by light alloy angles.

Aluminium alloy members of top-hat

or angle section are used for the pillars. cantrails, roof ribs, floor supports and cage-partition frames. The structure is

fitted to a platform body. In severe weather the structure is covered with tarpaulins.