This Lad3

Page 96

Page 97

Page 98

Page 103

If you've noticed an error in this article please click here to report it so we can fix it.

No Tramp

Says John F. Moon,

A.M.I.R.T.E. ALTHOUGH carrying a standar , model name, the Leyland Super Comet has little in common with the 12-ton-gross Comet which was in production at the time of the introduction of the Super Comet (September. 1958). It has been designed from the start as a genuine 14-ton-grass chassis.

I have carried out the first full-scale road test of a Super Comet, and find it an outstanding vehicle in all respects. The Super Comet is destined to be as popular—if not more so—as the Comet range over the past 11 years.

The Super Comet has many features which will appeal to both home and overseas operators. These include the attractive, comfortable and well-laidout cab; a good turn of speed; useful acceleration and hill-climbing performance; well-balanced suspension; light steering; and powerful, fade-free brakes.

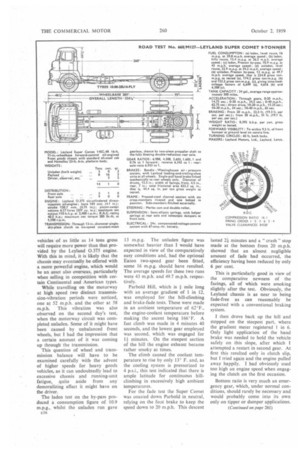

Five Types Offered At the time of its introduction the Super Comet range, which was fully described in The Commercial Motor on September 19, 1958, consisted of four basic types, but an additional model, a 9-ft. 10-in.-wheelbase dumper chassis, has since been introduced. The four original chassis, all of which are available with leftor right-hand drive and widths of 7 ft. 6 in. or 8 ft., have wheelbases of 16 ft. 11 in., 14 ft. 8 in., 12 ft. 6 in. and 8 ft. 1 in. The shortest is intended for tractor use at a gross train weight of 18 tons.

The 16-ft. 11-in.-wheelbase test chassis had the standard Leyland Vista-Vue all-steel, cab made by Motor Panels, Ltd., and Homallony 23-ft 6-in. platform body with light-alloy under frame, side raves and headboard, and timber decking. The chassis specification was standard, one of the few items of additional equipment being the sixth-speed overdrive ratio in the Albion-Leyland five-speed constantmesh gearbox.

An Albion-designed double-reduction real-axle was fitted; it had a ratio of 6.933 to 1, one of five optional finaldrive ratios. As an alternative axle a Leyland case incorporating an Eaton 18800 spiral-bevel two-speed driving head can be supplied.

The kerb weight of the complete vehicle, with full fuel tank, was 5 tons + cwt. and iron weights totalling 8 tons 16+ cwt. had been placed aboard. The distribution was such that the rear axle loading was exactly 9 tons, which is both the British legal and Leyland limit.

Good retardation figures Were obtained with. the foot brake, a commendable characteristic being the lack of grab or surge. When braking from 20 m.p.h. no wheel-locking occurred, but full-pressure stops from 30 m.p.h. caused the near-side rear wheel to lock. The maximum Tapley meter reading during these tests was in the

region of 80 per cent., approximately 20 per cent. higher than the average retardation efficiency indicated by the measured stopping distances.

Good figures were obtained also with the hand brake when applying it from 20 m.p.h., an average efficiency of 29 per cent. being obtained without difficulty. The single-pull hand-brake design is a particular feature of the Super Comet. The lever is cranked and placed to enable a strong pull to be obtained with a minimum of stretching and without it obstructing the driver when it is either released or applied. These are characteristics all too frequently missing from forward-control vehicles. Ls the chassis had covered only ut 2,500 miles before I tested it, likely that, after about 5,000 miles, better braking figures would be tined, because the facings would be -e evenly bedded-in.

,ntirely satisfactory acceleration res were recorded, second, third, rth and fifth gears being used for runs made from a standstill up to m.p.h. There was slight transmist rattle at 12 m.p.h. when making direct-drive tests between 10 m.p.h: 40 m.p.h., but generally the vehicle ed away from as low as 8 m.p.h. his ratio in an acceptable manner. LS the data panel shows, direct,e acceleration was not quite con

it, the acceleration rate dropping as the speed increased. This is mai with commercial vehicles when ;Ierating above 30 m.p.h. and the res indicate that the engine torque lighest where it counts most—at iparatively low speeds.

hree sets of fuel-consumption res were taken laden. The first over a hilly, twisting, 10-mite between Euxton and Langton )ass, taking in some of the mitts of Leyland. This is a particuf difficult route on which to keep a good average speed, but the rse was completed in 22 minutes teconds.

he consumption rate was 12.4 .h., which is acceptable in view of conditions. During the run the veh;cte was brought to rest four times in traffic and third gear was necessary for a couple of minutes on one of the hills.

By way of a routine check, a 5.9-mile circuit of the Southport road at Tarleton was made at an average speed of 29.8 m.p.h. In direct contrast to the conditions appertaining on the first test, when overdrive ratio was hardly ever used, this gear was employed for the complete circuit. The result was a consumption rate of 16 m.p.g.

Combination of the two figures indicates that under normal main-road conditions—which would be less severe than those occasioned by the hilly route, but not so easy as those found on the Tarleton circuit—a laden fuel figure of at least 14 m.p.g. should be returned if intelligent use is made of the overdrive. The rate would be in the region of 12-13 m.p.g. if the overdrive ratio were not fitted.

In view.of the proximity of Preston by-pass, Britain's only motorway on which commercial vehicles can travel at art unlimited pace, I made one fast run up and down this road, starting from a point ahead of the by-pass, at the northern end, so that the round trip totalled 17 miles.

This was completed at an average speed of 43 m.p.h. The speed would

have been higher had it not been necessary to slow down to 25 m.p.h. because of road works on one section of the north-bound carriageway, and the need to come to a complete standstill at the bottleneck caused by the Broughton roundabout.

Maximum speed observed on the speedometer during this run was appreciably above the highest marking on the dial, which is 60 m.p.h., whilst, except at the road works, the minimum speed occasioned by gradients when heading north was 27 m.p.h.fourth gear engaged—and that when heading south, 22 m.p.h.—third gear —on the hill at the Broughton end.

Even the comparatively slight gradients on the by-pass at least halved vehicle speed, consequently for efficient operation on motorways

vehicles of as little as 14 tons gross will require more power than that provided by the Leyland 0.375 engine. With this in mind, it is likely that the chassis may eventually be offered with a more powerful engine, which would be an asset also overseas, particularly when selling in competition with certain Continental and American types.

While travelling on the motorway at high speed two distinct transmission-vibration periods were noticed, one at 52 m.p.h. and the other at 58 m.p.h. This vibration was also observed on the second day's test, when the motorway circuit was completed unladen. Some of it might have been caused by unbalanced front wheels, but I had the impression that a certain amount of it was coming up through the transmission.

This question of wheel and transmission balance will have to be examined carefully with. the advent of higher speeds for heavy goods vehicles, as it can undoubtedly lead to excessive chassis and running-unit fatigue, quite aside from any demoralizing effect it might have on the driver.

The laden test on the by-pass produced a consumption figure of 10.9 m.p.g., whilst the unladen run gave 13 m.p.g. The unladen figure was somewhat heavier than I would have expected in view of the comparatively easy conditions and, had the optional Eaton two-speed gear been fitted, some 16 m.p.g. should have resulted. The average speeds for these two runs were 43 m.p.h. and 49.7 m.p.h. respectively.

Parbold Hill, which is 3 mile long with an average gradient of 1 in 12, was employed for the hill-climbing and brake-fade tests. These were made in an ambient temperature of 62°F., the engine-coolant temperature before making the ascent being 166°F. A fast climb was made in 4 minutes 40 seconds, and the lowest gear employed was second, which was engaged for 13 minutes. On the steepest section of the hill the engine exhaust became rather smoky at times.

The climb caused the coolant temperature to rise by only 13° F. and, as the cooling system is pressurized to 4 p.s.i., this test indicated that there is ample latitude for continuous hillclimbing in excessively high ambient temperatures.

For the fade test the Super Comet was coasted down Parbold in neutral, relying on the foot brake to keep the speed down to 20 m.p.h. This descent lasted 23 minutes and a " crash " stop made at the bottom from 20 m.p.h. showed that an almost negligible amount of fade had occurred, the efficiency having been reduced by only 6 per cent.

This is particularly good in view of the comparative newness of the facings, all of which were smoking slightly after the test. Obviously, the Leyland chassis is as near to being fade-free as can reasonably be expected with a conventional braking system.

I then drove back up the hill and stopped on the steepest part, where the gradient meter registered 1 in 6. Only tight application of the hand brake was needed to hold the vehicle safely on this slope, after which I attempted a restart in second gear. At first this resulted only in clutch slip, but I tried again and the engine pulled away happily. I had obviously used too high an engine speed when engaging the clutch on the first occasion.

Bottom ratio is very much an emergency gear, which, under normal conditions, should rarely be necessary and would probably come into its own only on tipper or dumper applications. .2-to-1, or even the 555540-1, ild beneficially be employed aal road haulage: certainly, for use, one of these high-ratio ith the overdrive-top gearbox ive an that any operator would in respect of maximum speed. the load removed, two unladen sumption tests were conone on the motorway (as detailed) and the other on the irt road at Tarleton. This test gave a fuel figure of 23.9 it an average speed of 34.2

the figures obtained suggest der main-road haulage condihen the vehicle has to return an overall fuel figure in the ,f 17 m.p.g. should be obtained ators.

ad the Comet handled excepwell, both laden and unladen. eering is remarkably light :h not dangerously so), partly of the use of a 21-in.-diameter wheel and low gearing. Power is offered but this should e necessary, except for off-theplications. Over some surfaces ring wheel tended to kick a id this effect was accentuated mn shake, the upper end of ering column being unsup ways, the Albion gearbox was it to use, the clutch being virnnecessary for normal chang:I entirely superfluous when changes from fifth to sixth. the original forward-control which had a remotely mounted rer, the Super Comet and the Comets have the gear lever directly on the box.

Easy Gear Changes

L this arrangement results in d gear changing, but not so in of the Leyland, although careagement of first, third, fifth or can occasionally result in the anging his elbow on the back ab.

le noise is by no means pro f and all the controls are well I cannot pretend to be entirely ibout the central speedometer, nowledge this as being a short .andardization on leftor rightive chassis.

suspension behaved well, it occasionally I noticed that it springs gave a slightly harsh ['here was commendably little ce between the suspension .ristics whether laden. or , which justifies the Leyland rs' decision to employ highm springs at both axles. Maxi:fiection is about 41 in. in each

The Super Comet corners like a sports car, and the wide range of (vision should enable drivers to take advantage of this fact.

Braking effect is entirely proportional to pedal travel and the remotely mounted DI valve, which is controlled by a conventional pedal, gives progressive characteristics. Because the pedal travel is fairly long, there is little fear of a driver employing excessive braking power when travelling empty.

The cab is good for a quantity-production all-steel design and there is plenty of room for a driver and mate to sit in comfort. The roof and upper half of the rear panel have glass-fibre insulation, and ventilation is provided by swiveling quarter-lights and winddown windows in the doors, and large scuttle ventilators.

Provision is made for the installation of heating and demisting equipment, which is housed between the inner and outer front panels. The cab has a three-point rubber mounting the two rear mountings being widely spaced and incorporating rebound springs.

Maintenance Tests

With what time there was remaining at the end of the second day's testing, I conducted a few maintenance tasks to assess the general accessibility of those items likely to be serviced during normal operations. Level checks were made first, including the water (15 seconds); engine oil (I minute); gearbox oil (55 seconds); rear-axle oil (1 minute 10 seconds); air-cleaner oil (I minute 20 seconds); and batteries (3 minutes 15 seconds).

Dealing with these points separately, the times quoted for the engine oil and air-cleaner oil checks include removal and replacement of the main enginecowl panel, which is secured by two simple clips. The time for the inspection of the battery levels includes removal of the passenger seat and displacement of the driving seat.

The range of adjustment of the driving seat allows it to be moved sufficiently for the battery-cell levels to be seen. The rear axle is unusual for a current design in having separate filler and level plugs.

There are two fuel filters in the system, a primary felt-element unit mounted on the near-side side member immediately ahead of the fuel tank, and a main paper-element filter carried on the near side of the engine ahead of the air cleaner. I was able to remove and replace the element of the primary filter ..in 1 minute 34 seconds, whilstthe element of the second filter was taken out and put back in 2 minutes 20 secOnds: This time again .includes removal and replacement, of the cowl—tasks which add up to 20 seconds by themselves.

Fuel-injector removal proved to be not as difficult as would appear, although it is necessary to take off the valve-gear cover to gain access to the injectors. All the injectors are then equally accessible, and from start to finish the removal of No. 3 injector. occupied 101 minutes. The fuel system was next bled at the injection

pump in 1 minute 20 seconds. • Because of the worm-type slack adjusters, which are standard equipment on the Super Comet, brake adjustment was particularly easy. The front brakes were reset in 21 minutes and the rear brakes in 11 minutes, all the wheels being jacked up.

Awkward Carrier I then tackled what was obviously going to be a heavy job—removal and replacement of the spare wheel. This is made particularly awkward because the carrier is tucked well under the chassis fret& and the wheel is tight up against the side members.

In the case of the test vehicle, manceuvring room was further restricted by the long body rear overhang. The wheel is secured by four nuts, which have to be loosened from underneath, but single-handed I managed to get the wheel off its carrier and on to the ground in 1 minute 37 seconds.

Short of using a complicated layout of jacks and planks, I doubt whether anybody could replace the wheel single-handed: it was difficult enough with assistance, and at the end of 34 minutes, a Leyland engineer and I had finally got it in place, after which we both felt completely exhausted. With this type of carrier for a 10.00-20-in. tyre and wheel, a driver might have to leave the wheel on the road after a single-handed change.

Attending to the electrical system, I found that I required just over 61 minutes to change a fuse wire. The wire itself took only 1 minute 55 seconds to change, but I spent 2 minutes 5 seconds removing the panel behind which the fuse box is. located and 21 minutes in replacing it, there being six bolts to remove and.refit.

The Leyland Super Comet 14SC.4R 16-ft. 11-in.-wheelbase chassis and cab, as tested, is listed at £2,266 for sale in Great Britain. The optional twospeed axle costs a further £75, and power-assisted steering—if it is really thought to be necessary—can be obtained for an extra £88 5s. All this adds up to good value for money, and I confidently expect to see Leyland Super Comets on British and overseas roads for many years to come.