Volvo laps it up

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

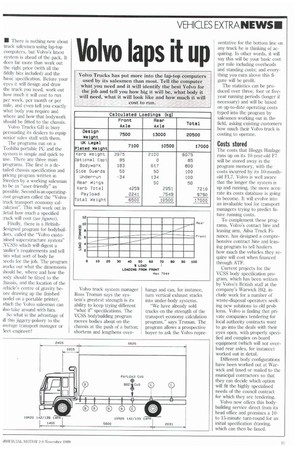

Volvo Trucks has put more into the lap-top computers used by its salesmen than most. Tell the computer what you need and it will identify the best Volvo for the job and tell you how big it will be, what body it will need, what it will look like and how much it will cost to run.

Volvo truck system manager Ross Troman says the system's greatest strength is its ability to keep trying different "what if' specifications. The VCSS bodybuilding program moves bodies about on the chassis at the push of a button; shortens and lengthens over hangs and can, for instance, turn vertical exhaust stacks into under-body systems.

"We have already sold trucks on the strength of the transport economy calculation program," says Troman. The program allows a prospective buyer to ask the Volvo repre sentative for the bottom line on any truck he is thinking of acquiring. In other words, it will say this will be your basic cost per mile including overheads and standing costs; and everything you earn above this figure will be profit.

The statistics can be produced over three, four or fiveyear running periods (longer if necessary) and will be based on up-to-date operating costs typed into the program by salesmen working out in the field, asking existing customers how much their Volvo truck is costing to operate.

Costs stored The costs that Bloggs Haulage runs up on its 10-year-old F7 will be stored away in the program memory, with the costs incurred by its 10-monthold FI,7. Volvo is well aware that the longer the system is up and running, the more accurate its costs database is going to become. It will evolve into an invaluable tool for transport managers trying to predict future running costs.

To complement these programs, Volvo's contact hire and leasing arm, Ailsa Truck Finance, has designed a comprehensive contract hire and leasing program to tell hauliers how much the vehicles they require will cost when financed through ATF.

Current projects for the VCSS body specification program, which has been written by Volvo's British staff at the company's Warwick 1-1Q, include work for a number of waste-disposal operators seeking new solutions to old problems. Volvo is finding that private companies tendering for local authority contracts want to go into the deals with their eyes open, with properly specified and complex on-board equipment (which will not overload rear axles, for instance) worked out in detail.

Different body configurations have been worked out at Warwick and faxed or mailed to the municipal contractors so that they can decide which option will fit the highly specialised needs of the council contract for which they are tendering.

Volvo now offers this bodybuilding service direct from its head office and promises a 10to 15-minute turn-round for an initial specification drawing, which can then be faxed.