Evaluating washers

Page 124

Page 125

If you've noticed an error in this article please click here to report it so we can fix it.

IN Washing is a dirty word when it comes to any type of commercial vehicle. Nobody likes doing it and a lot of money is involved, but it is necessary and, because of the amazing ability of lorries in particular to get dirty on the shortest of runs, must be carried out with monotonous regularity.

Vehicles delivering foodstuffs to high street stores must be kept clean, and they may even get washed twice a day in the winter. The image of a luxury coach costing over £100,000 can be ruined if it arrives at a pick-up point in a dirty condition.

A lot of time and money is spent each year on keeping vehicles clean; manpower, vehicle downtime, equipment, chemicals and water add up to a significant proportion of fleet maintenance costs. After all, a truck, say, may be serviced once every six weeks, but it is probably washed half a dozen times in that period.

While there are several ways to wash vehicles, from using a bucket and brush to automatic roll-over gantry brush systems, the small fleet owner could not hope to justify the purchase of a gantry wash system but it is impracticable to keep a large fleet clean by any other means.

Indications of quality

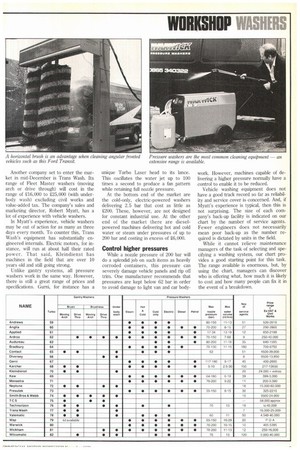

With such a demand for washing and a variety of ways to do it, there will be no surprises in the fact that we found 24 companies offering such equipment — there are probably others. On the following page we print a table of the companies, an indication of the range of equipment they offer, the size of their service operation and the price range. While care has been taken compiling this table, corn plete accuracy cannot be guaranteed and anyone wishing to purchase equipment should check all details for themselves.

When looking for a washing system, as with most other tasks, the price is not the only indication of a product's quality and reliability or even that it is the correct equipment for your situation. How many washes per week are required before the higher capital investment of a gantry system (some capable of cleaning an articulated vehicle in less than one minute) outweighs the time taken by a pressure washer? Can any gantry, with or without brushes, clean a tanker properly? Answering these questions and specifying the correct washing system for any fleet must be dealt with on an individual basis.

However, there are a few generalities and exceptions worth a mention. For instance, a gantry system with a horizontal brush may be favourable when cleaning vehicles with an angled front like the Optare City Pacer or the Ford Transit. Contact will shape the brushes in its washers to clean road tankers, but this may become detrimental when cleaning other vehicles.

Brushless systems will clean all shapes of vehicle but they use more water and, some would argue, they do not clean the majority as well as those with brushes. Ardrox makes a system that combines brushes with the brushless water jets.

Where space is at a premium, a drivethrough system has the advantage over a moving-gantry one. If pushed still further, the two gantries on a brushless system can be sited close to each other with the vehicle making two passes, but this negates much of the time saved by using a drive-through washer.

An interesting development in gantry washers is soon to be offered by Transport Cleaning Services (TCS). This is a portable system mounted on a dedicated semi-trailer, carrying enough water for 15 washes and its own generator for power. Once the semi-trailer is on site, the gantry is swung out and travels along the trailer during washing.

When these units become available next year they will be offered as a franchised operation, probably on a lease arrangement, and will cost around £58,000. A further use of this system is to permanently mount it flush onto. a wall and swing it out when requiring to wash a vehicle — a massive space saving.

Another company set to enter the market in mid-December is Trans Wash. Its range of Fleet Master washers (moving arch or drive through) will cost in the range of £16,000 to £25,000 (with underbody wash) excluding civil works and value-added tax. The company's sales and marketing director, Robert Myatt, has a Lot of experience with vehicle washers.

In Myatt's experience, vehicle washers may be out of action for as many as three days every month. To counter this, Trans Wash's equipment has substantially engineered internals. Electric motors, for instance, will run at about half their rated power. That said, Kleindienst has machines in the field that are over 10 years old and still going strong.

Unlike gantry systems, all pressure washers work in the same way. However, there is still a great range of prices and specifications. Gurni, for instance has a unique Turbo Laser head to its lance. This oscillates the water jet up to 100 times a second to produce a fan ,pattern while retaining full nozzle pressure.

At the bottom end of the market are the cold-only, electric-powered washers delivering 2.5 bar that cost as little as £200. These, however, are not designed for constant industrial use. At the other end of the market there are dieselpowered machines delivering hot and cold water or steam under pressures of up to 200 bar and costing in excess of 26,000.

Control higher pressures

While a nozzle pressure of 200 bar will do a splendid job on such items as heavily corroded containers, this pressure can severely damage vehicle panels and rip off trim. One manufacturer recommends that pressures are kept below 62 bar in order to avoid damage to light van and car body work. However, machines capable of delivering a higher pressure normally have a control to enable it to be reduced.

Vehicle washing equipment does not have a good track record so far as reliability and service cover is concerned. And, if Myatt's experience is typical, then this is not surprising. The size of each company's back-up facility is indicated on our chart by the number of service agents. Fewer engineers does not necessarily mean poor back-up as the number required is dictated by units in the field.

While it cannot relieve maintenance managers of the task of selecting and specifying a washing system, our chart provides a good starting point for this task. The range available is enormous, but, by using the chart, managers can discover who is offering what, how much it is likely to cost and how many people can fix it in the event of a breakdown.