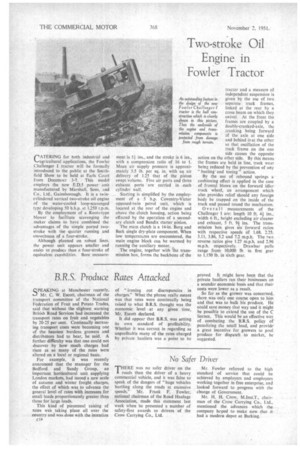

Two-stroke Oil Engine in Fowler Tractor

Page 54

If you've noticed an error in this article please click here to report it so we can fix it.

CATERING for both industrial and —,agricultural applications, the Fowler Challenger I tractor will be formally introduced to the public at the Smithfield Show to be held at Earls Court from Decemoer 3-7. This model employs the new E.D.5 power unit manufactured by Marshall, Sons, and Co., Ltd., Gainsborough. It is a twincvlindered vertical two-stroke oil engine of the water-cooled loop-scavenged type developing 50 b.h.p. at 1,250 r.p.m.

By the employment of a Roots-type blower to facilitate scavenging the maker claims to have combined the advantages of the simple ported twostroke with the quieter running and smoothness of a four-stroke.

Although planned on robust lines. the power unit appears smaller and easiet to produce than a four-stroke of equivalent capabilities. Bore measure ment is 51 ins„ and the stroke is 6 ins., with a compression ratio of 16 to 1. Mean air supply pressure is approximately 3.5 lb. per sq. in. with an air delivery of 1.25 that of the piston swept volume. Five air ports and three exhaust ports are carried in each cylinder wall.

Starting is simplified by the employment of a 5 lup. Coventry-Victor opposed-twin petrol unit, which is located at the rear of the engine and above the clutch housing, action being effected by the operation of a secondary clutch and Bendix starter pinion.

The main clutch is a I4-in. Borg and Reck single dry-plate component. When low temperatures are encountered, the main engine block can be warmed by runniiig the auxiliary motor.

The engine, together with the transmission box, forms the backbone of the

tractor and a measure of independent suspension is given by the use of two separate track frames, linked at the rear by a cross beam on which they swivel. At the front the frames are coupled by a double-cranked-axle, the cranking being forward of the axle at one side and behind it,at the other so that oscillation of the track frame on the one side causes the opposite action on the other side. By this means the frames are held in line, track wear being reduced by the prevention of any "heeling and toeing" action.

By the use of rebound springs a cushioning effect is applied in the case of frontal blows on the forward idlertrack wheel, an arrangement which also provides relief should any foreign body be trapped on the inside of the track and passed round the mechanism.

Over a 11 measurements of the Challenger I are: length 10 ft. 4-/E ins., width 6 ft., height excluding air cleaner and exhaust, 5 ft. 91. ins. The transmission box gives six forward ratios with respective speeds of 1.68. 2.25; 3.11, 3.86, 5.2 and 7.2 m.p.h. The two reverse ratios give 1.27 m.p.h. and 2.96 m.p.h. respectively. Drawbar pulls range from 10,000 lb. in first gear to 1.150 lb. in sixth gear. An outstrmding feature in the design of the new Fowler Challenger I tractor is the hull construction which is clearly shown in this picture. Thus the underside of the engine and transmission components is protected from damage