TYRES AND WHEELS.

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

Some Interesting Features of the New Wheel Designs with Large Pneumatics in View.

HE IMPORTANT question of tyre and wheel

arrangeinent an commercial and publie-service

vehicles is one winch is still in the melting pot. There is some difficulty in deciding at the moment what will be the ultimate trend of the tyre and wheel problem.

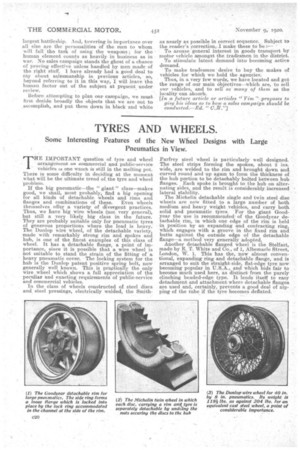

If the big pneumatic—the " giant " class—makes good, we shall, most probably, find a big opening for all kinds of detachable wheels and rims and flanges and combinations of these. Even wheels themselves offer a variety of lAvergent practices. Thus, we have big wire wheels (not very general), but still a very likely big class in the future. They are probably suitable only for pneumatic tyres of generous proportions where the load is heavy. The Dunlop wire wheel, of the detachable variety, made with remarkably strong rim and spokes and hub, is one of the finest examples of this class of wheel. It has a detachable flange, a point of importance, since it is possible that a wire wheel is not suitable to stand the strain of the fitting of 'a heavy pneumatic 'cover. The locking system for the hub is the Dunlop patent positive spring bolt, now generally well known. This is practically the only wire wheel which shows a full appreciation of the peculiar and exacting requirements of public-service and commercial vehicles.

In the class of wheels constructed of steel discs and steel pressings, electrically welded, the Smith

Parfrey steel wheel is particularly well designed. The steel strips forming the spokes, about 2 ins. wide, are welded to the rim and brought down and curved round and up again to form the thickness of the hub portion to be detachably bolted between hub flanges. Each spoke is brought to the hub on alternating sides, and the result is considerably increased lateral stability.

The Michelin detachable single and twin steel disc wheels are now fitted to a large number of both medium and heavy weight vehicles, and carry both solid and pneumatic tyres. For the giant Goodyear the use is recommended. of the Goodyear detachable rim, in which one edge of the rim, is held in position by an expanding and contracting ring, which engages with a. groove in the fixed rim and butts against the 'outside edge of the detachable flange—a method very generally adopted. i

Another detachable flanged wheel s the Stelfast, made by E. T. White and Go. of 1, Albemarle Street, London, W. 1. This has the, now almost conventional, expanding ring and detachable flange, and is arranged to suit the straight-side, flat-edge tyre now becoming popular in U.S.A.' and which bids fair to become much used here, as distinct, from the purely clinching beaded-edge type. It lends itself to easy detachment and attachment where detachable flanges are used and, certainly, prevents a good deal of nip-, ping of the tube if the tyre becomes deflated.

Another detachable wheel is that used by the A.E.C., where the wheel of steel is detachable from the fixed hub, the wheel hub being provided with dog slots to take the drive, and the fixed and detachable hubs being parallel sliding fits upon each other and locked by four bolts with the Ross double self-locking nut. It is a simple and effective method of attachment and detachment.

In the solidor semi-solid type of tyred wheels, the Macintosh N.A.P. (normal air pressure) tyre and rim form a combination very suitable for commercial purposes. Here, two detachable flanges, bolted through a wooden felloe, hold a hollow tyre in position by beaded edges at the foot of the tyre. A plate of steel between the two inside edges of the tyre, and having a bevelled edge, causes the tyre inside edges to be sealed.

The Nobby, cord tyre and detachable flange and rim offers a solution to three problems. The first is the inaking of a stout cover of the non-beaded variety which will be quite firm and yet easily detachable. The foot of the aides of the tyre are built up of cord layers around two independent sets of inextensible Seel-cable wire, which keep the inner periphery of he tyre dead down en the seat. The Type E rim is arranged to allow of the detachmelt of the tyre complete and inflated on the rim, or the detachment of the tyre deflated from the rim —a combination which adds immeasurably to the utility of the device. The detachable flange is held in position by a spring ring, which, when sprung out, allows the rim to be drawn off in the usual way, the novelty here being not so much in the application of the ring as in its shape.

,Theitrim beds up on one side on a taper seat on the fixed rim on the felloe. At the other side a wedge ring wedges between the rim and the wheel, aud is held in position by bolts and nuts and specially-shaped lock plates, which are anchored against the wheel rim at one end and are forced against the V-ring at the 'other.

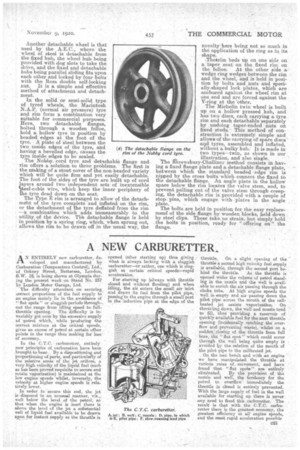

The Michelin twin wheel is built up on a hollow pressed hub, and has two discs, each carrying a tyre rim and each detachable separately by undoing taoier-ended nuts on fixed studs. This method of construction is extremely simple and allows of the carrying of spare discs arld tyres' assembled and inflated, without abulky hub. It is made in two types—twin, as shown in our illustration, and also single.

The Shrewsbury-Challiner method consists in having a fixed flange plate and a, detachable flange plate, between which the standard beaded edge rim is nipped by the cross bolts which connect the fixed to the detachable flange. An angle plate in the hollow space below the rim locates the valve stem, and, to prevent pulling out of the valve stem through -creeping, the detachable rim is. provided with a couple of stops pins, which engage with plates in the angle , plate.

The bolts are held in position for the easy replacement of the side flange by wooden blocks, held down by steel clips. These take no strain, but simply hold the bolts in position, ready for "offering on' the the flange.