OIL-FIRED STEAM• WAGON BOILERS.

Page 10

Page 11

Page 12

If you've noticed an error in this article please click here to report it so we can fix it.

A Description of the Scarab Method of Utilizing Heavy Oils for Steam Wagon • Fireboxes, and the Results of a Test Run.

THE COAL STRIKE, whether it be finished before this article appears in print or continues for some Considerable time after, will turn the attention of many users of steam road vehicles to the question of utilizing other fuels to replace the coal or coke at present: required. Even before the strike, one of the greatest difficulties in the efficient running of steam wagons and .tractors was the problem of obtaining good quality fuel. When a wagon commenced a journey with its bunker full of good steam coal, it often had to 'purchase coal of inferior quality en route to continue the journey, or to return, and many 'complaints have been lodged against the owners of these vehicles because of the excessive amount of smoke produced ; fortunately, it has been realized that this smoke is due to the impossibility of obtaining suitable fuel at all times.

The possibility of using heavy oil as a fuel for steam wagons and tractors has been favourably commented upon in the pages of this journal from time to time, and it would appear that the Scarab Oil Burning Co., Ltd., of 28, Charles Street, London, S.W. I, have achieved this object. At present only one road vehicle in London is fitted with the Scarab patent burners and oil-burning system, but it has been rimning. in a most satisfactory way during the past six weeks. The system was developed in Mesopotamia for military purposes, and since then has been applied to almost every •type of furnace. Complete installations have been supplied to the leading Tailway companies in England, Egypt, and Mesopotamia, and some hundreds are at present in use on kitchen ranges, heating installations, stationary boilers, ete.,, so that the system is by no means an experimental one, but has achieved considerable success before its application to a commercial motor vehicle in service. Provided that special arrangements can be made for starting the burners from cold and for keeping them in operation without undue attention on the part of the driver, liquid fuel has many advantages over coal. The vehicle using it has greater fuel-carrying capacity, and, consequently, greater radius of action; the steam-raising capabilities are exceptionally good; there is no clinkering or wear and tear of firebars; and, if the fuel is burnt with its correct proportion of air, no sparks, dust, or smoke are produced, and no cleaning of flues, fireboxes, and smokeboxes is required.

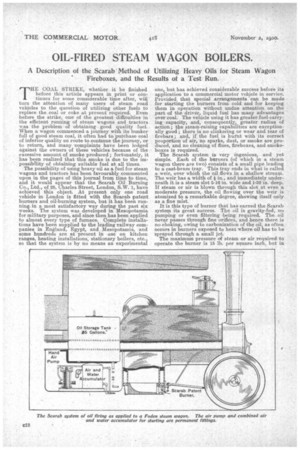

The Scarab system is very ingenious, and yet simple. Each of the burners (of which in a steam wagon there are two) consists of a small pipe leading to a cast-brass tray. This tray ends in what is called a-weir, over which the oil flows in a shallow stream. The weir has a, width of â in., and immediately underneath it is a steam slot 5-16 in. wide and 1-.32 in. deep. If steam or air is blown through this slot at even a moderate pressure, the oil flowing over the weir is atomized to a remarkable degree, showing itself only. as a fine mist.

It is this type of burner that has earned the Scarab • system its great success. The oil is gravity-fed, no pumping or even filtering being required. The oil never passes through fine orifices, and hence there is no. choking, owing to carbonization of the oil, as often occurs in burners exposed to heat where oil has to be sprayed through a small jet. The maximum pressure of steam or air required to operate the burner is 15 lb. par square inch, but in actual practice perfect atomization is obtained with pressures as low as 5 lb. per square inch. Each nozzle is 'contained in a cast-iron casing, and projects into the firebox from 1 in. to 1i in. The air necessary for combustion passes between the casing and the nozzle. The steam necessary for atomizing the oil is obtained from the wagon boiler, and it will be readily understooa that this steam not being available when the boiler is cold some method of starting and. keeping the burners in operation until the necessary head of steam is generated in the boiler is essential.

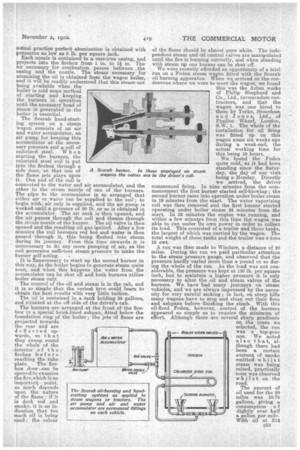

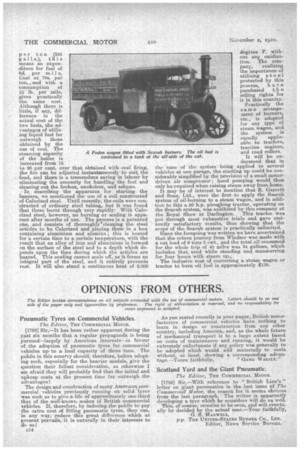

The Scarab hand-starting system on a steam wagon consists of an air and water accumulator, an air pump for keeping this accumulator at the necessary pressure and a coil of colorized steel. When starting the burners, the oalorized steel coil is put into the firebox through a side door, so that one of the flame jets plays upon it. One end of the coil is connected to the water and air accumulatoi'y and the other to the steam nozzle of one of the burners. The pipe to the accumulator is so arranged that either air or water can be supplied to the coil ; to begin with, air only is supplied, and the air pump is worked until a pressure of 20 lb. or so is obtained in the accumulator. The air cock is then 'opened, and the air passes through' the coil and thence through the steam nozzle of the burner. , The oil valve is then, opened and the resulting oil gas ignited. After a few minutes the coil becomes red hot and water is then passed through it, this being flashed into steam during its journey. From this time onwards it is unnecessary to do any more pumping of air, as the coil generates sufficient steam pressure to make the burner self-acting. It is unnecessary to start up the second burner in this way, as the boiler begins to generate steam quite soon, and when this happens the water from the accumulator can be shut off and both burners utilize boiler steam only. • The control of the oil and steam is in the cab, and it is so simple that the veriest tyro could learn to obtain the best results with very little tuition.

The oil is contained in a tank holding 35 gallons, and situated at the off side of the driver's cab.

The burners are arranged at the front of the firebox in a special brick-lined _ashcan, fitted below the foundation ring of the boiler ; the jets of flame are projected towards the rear and are deflected upwards, so that they sweep round the whole of the -interior of the, firebox before reaching the tube plate. The fire

box door can be aapump OTER NEEDLE

A Scarab burner. In those wagons the valves are in of the flame should be almost pure white. The independent steam and oil control valves are manipulated until the fire is burning correctly, and when standing with steam up one burner can be shut off. We were recently afforded an opporttinity of a trial run on a Fed en steam wagon fitted with the Scarab oil-burning apparatus. When we arrived at the rendezvous where we were to meet the wagon, we found

this was the Acton works of Philip Shepherd and Co., Ltd., tarmacadam contractors, and that the wagon was one hired to them by Yorke, Stoneham and Jones, Ltd.' of Pimlico Wharf, London, S.W. 1. The whole of the installation for oil firing was fitted up on this wagon some six weeks ago during a week-end, the actual working time for this being 16 hours.

We found the Foden

quite cold, as it had been standing since the Saturday, the day of our visit being a Monday. Directly we, arrived, the driver commenced firing. In nine minutes from the commencement the first burner started self-blowing; the second burner came into operation under boiler steam in 19 minutes from the start. The water -vaporizing coil was then removed and the first burner started operating under boiler steam 24 minutes from the start. In 32 minutes the engine was running, and within a few minutes from this time the wagon was able to run under its own power in order to collect its load. This -consisted of a trailer and three tanks, the largest of which was carried by the wagon. The total weight of these tanks and the trailer was 4 tons 15 cwt.

A run was then made to Windsor, a distance of 20 miles. During the run we paid particular attention to the steam pressure gauge, and observed that the pressure hardly varied more than a pound or so during the whole of the run. As the load was not considerable, the pressure was kept at 130 lb. per square inch, but to maintain a higher pressure it is only necessary to alter the oil and steam valves of the burners. We have had many journeys on steam vehicles, and we are always impressed by the necessity for very eareful stoking ; in fact, on steep hills ' many wagons have to stop and clean out• their fires and ashcans before finishing the climb. With this oil-fired Foden, however, control of the burners appeared so simple as to require the minimum 01 effort. Although there are several sharp gradients on the route we selected, the run was a. top-gear one. We noted also that, although there had been a certain amount of smoke emitted whilst steam was being raised, practically none was observed whilst on the road. employed on steam the driver's cab,

-4.BOILER STERN valves

The amount of

oil used for the 20 miles was 10.75 gallons, giving a consumption o f dightly over half a gallon per...mile. With oil at £12

per ton (240

galls.), this means an expenditure for fuel of 61. per mile. Coal at 70e. per ton, and with a. Consumption of 15 lb. per mile, gives practically the same cost. Although there is little, if any, difference in the actual cost of the two fuels, the advantages of utilizing liquid fuel far outweigh those obtained by the use of coal. The steaming capacity of the boiler is increased from 15 to 20 per cent. over that obtained with coal firing, the fire can be adjusted instantaneously tosuit the load, and there is a tremendous saving in labour by eliminating the necessity for handling the fuel and cleaning out the firebox, smokebox, and ashpan. In describing the apparatus for starting the burners, we mentioned the use of a coil constructed of Calorized steel. -Until recently, the coils were constructed of ordinary steel tubing, but it was found that these burnt through very rapidly: With Calorized steel, however, no burning or scaling is apparent after months of use. The process is a patented one, and consists of thoroughly•cleaning the steel articles. to be Calorized and placing them in a box containing aluminium and alumina ; this is heated for a certain time to a certain temperature, with the result that an alloy of iron and aluminium is formed on the surface of the steel and to a depth which depends upon the time during which the articles are heated. This coating cannot scale off, as it forms an integral part of the steel, and it entirely prevents rust. It will also stand a continuous heat of 2,000 degrees F. without any oxidization. The company, realizing the importance of utilizing steel protected by this process, h a. v e purchased t h e selling rights for it in this country.

Practically the sam e arrangement of burners, etc., is adopted for any type of steam wagon, and the system • is equally applieable to tractors, traction engines, and road rollers.

It will be understood that in the case of the system being applied to several vehicles at one garage, the starting up could be considerably simplified by the provisibn of a small motordriven air compressor ; hand pumping would then only be required when raising steam away from home. It may be of interest to mention that R. Garrett and Sons, Ltd., were the first to apply the Soarab system of oil-burning to a steam wagon, and in addition to this a 50 h.p. ploughing tractor, operating on the Scarab system, was exhibited by this company at the Royal Show at Darlington. This tractor was put through most exhaustive trials and gave eminently satisfactory results, thus showing that the scope of the Scarab system is practically unlimited. Since the foregoing was written we have ascertained that the return journey from Windsor was made with a net load of 9 tons 5 cwt., and the total oil consumed for the whole trip of 40 miles was 24 gallons, which includes that used while standing and manoeuvring for four hours with steam up.

The inclusive cost of converting a. steam wagon or tractor to burn-oil fuel is, approximately £118.