• The cab floor and engine A.4 hump was

Page 70

Page 71

Page 72

Page 73

If you've noticed an error in this article please click here to report it so we can fix it.

• designed to

;4. • accept the larger

275hp 10-litre Cummins or the 301hp

12-litre Perkins Tx Eagle engines as alternatives to the more powerful C-Series unit. It was uprated to 26 tonnes from May 1992 and Euro-1 engines were introduced in August 1993.

Purpose-built specifications include 6x2, 6x4 and even 6x6 chassis with rust-free GRP composite day or sleeper cabs; constant-mesh and synchromesh transmissions; rubber, air or steel suspensions; power options from 240375hp (179-2801(W); and a whole range of linefit chassis options.

• OPERATORS

Douglas Holdings has played a significant role in the building of the UK motorway network, starting with the Ml and doing its bit on the M5. M6. M40 and M42. Douglas Concrete was the smallest company in a group which, back in the sixties, ran around 1,000 vehicles. Today, it is once again an independent family firm with its base at Barton and nine depots throughout the Midlands.

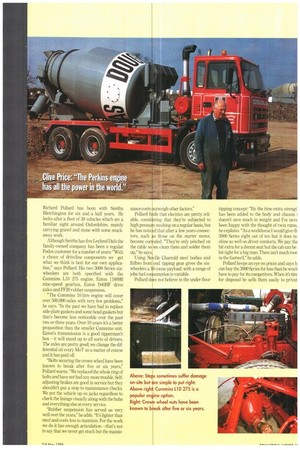

Concrete production and transport director Clive Price has worked for Douglas Concrete for some 25 years.

He has a hands-on approach to running the fleet of 41 six-wheel mixers, two six-wheel tippers, 10 eight-wheel tippers and the odd tanker; 23 of them are Kxlens.

"When I joined the company we ran Commers," he recalls. "We moved on to AECs and then Leylands with the 511 engine. W. restricted engine speed to 2,400rpm, down from 2,600rpm, and had one do over 500,000 miles. The IL, II was also good for us and when Daf took control we moved on again with their 11A-litre engine.

"I have always believed in having a motor that is bigger than what the job requires," he adds. "When the 75-Series came along we were told to take it with the Daf engine or leave it—so we went to Foden.".

Two and a half years ago Price settled for the 3000 Series but Foden's build flexibility allowed him to specify a vehicle that suits the idiosyncrasies of concrete mixer operation.

"All our drivers are employees and so they need to make a fast turnround on site," he explains. "If they get stuck they usually get the one chance to pull out, otherwise they just dig in deeper. Over the past two and a half years I've only had to recover two so [think we have it about right."

The formula consists of a 12-litre Perkins' Eagle Tx335 engine driving through a 15.5in Spicer twin-plate clutch to a Fuller RTX 116098 nine-speed box, 1760 Series propshaft and Eaton axles with Rockwell hubs and brakes.

Initially Price asked for steel springs at the rear but he settled for the FF20 rubber suspension even though it offered less articulahon. The 75-tonne front axle is supported by a two-leaf spring on the nearside and a stiffer three-leaf spring on the offside to counteract the load, which tends to move up the side of the drum. Foden assured him that its 9mmthick chassis would never break but even a slight bend could cause loss of drive for the roller path on the mixer drum, so a 6mm flitch was added from the back of the chassis through to the gearbox. A Knowles PTO, sandwiched between the engine and the bell housing, is ideally placed for short, neat plumbing to the mixer drive. The result is a mixer chassis with a shortened 3.91m wheelbase plated at 25 tonnes and able to carry 6m3 of concrete.

"The cost was less than we were quoted for the 75 Series," says Price, "and we pay for them over three years through Paccar finance. The engine has all the power in the world and, although it runs all the time turning the mixer, it does 8.5mpg. We had a fiveyear replacement plan with the Leylands but I expect these Foclens to last longer. They're all sold to one dealer who retails them out of the area.

"A Cummins L10 would have given us similar power to the Perkins," he accepts, "but it's less suited to our operation at tickover. We did have one engine go down and Foden changed it right away—its air filter wasn't fitted right from new and it let in dirt. Drain intervals have been increased from 12,800km to 16,000km by using a premium quality oil from Morris of Shrewsbury. The twin-plate clutch gives us three years' trouble-free service while a single plate wouldn't last out 12 months. We specify a 4.56:1 final drive and the transmission's low crawler gear gives us good performance on-site.

"The dust cover on the diff-lock switch didn't function very well until Foden modified it," he reports. "Our trucks go through the wash twice every load so they get a lot of water thrown at them—we had some trouble with relays until we damp-proofed them. Automatic lubrication on the chassis uses soft grease. With the water the GRP cab is a bonus; it will never rust.

"Occasionally a steel bumper gets a knock on site and steps sometimes get bent but they are easy enough to put right.

Chris Hodge:

"We haven't wanted many bits," Price adds. "Charnvaiod Trucks provides what we need. When we had a problem with the power steering they didn't have the part we wanted but got one from the factory by the time we brought the truck back in to our workshop. It's a strong truck, very well built, and we don't get any complaints from the drivers.

"The top radiusrod bearings on the rear suspension might give us a bit of a problem if they need replacing," he concludes, "the mixer drum is in the way."

Fleet engineer Richard Pollard has been with Smiths Bletchington for six and a half years. He looks after a fleet of 30 vehicles which are a familiar sight around Oxfordshire, mainly carrying gravel and stone with some muckaway work.

Although Smiths has five Leyland Dafs the family-owned company has been a regular Foden customer for a number of years: "With a choice of driveline components we get what we think is best for our own application," says Pollard. His two 3000 Series sixwheelers are both specified with the Cummins L 10 275 engine, Eaton 1160913 nine-speed gearbox, Eaton D4OHF drive axles and FF20 rubber suspension.

"The Cummins 10-litre engine will cover over 500,000 miles with very few problems," he says. "In the past we have had to replace side-plate gaskets and some head gaskets but that's become less noticeable over the past two or three years. Over 10 years it's a better proposition than the smaller Cummins unit. Eaton's transmission is a good tipperman's box—it will stand up to all sorts of drivers. The axles are pretty good; we change the differential oil every MoT as a matter of course and it has paid off.

"Bolts securing the crown wheel have been known to break after five or six years," Pollard warns. "We replaced the whole ring of bolts and have not had any more trouble. Selfadjusting brakes are good in service but they shouldn't put a stop to maintenance checks. We put the vehicle up on jacks regardless to check the linings visually along with the hubs and everything else at every service.

"Rubber suspension has served us very well over the years," he adds. "It's lighter than steel and costs less to maintain. For the work we do it has enough articulation—that's not to say that we never get stuck but the mainte nance costs iutweigh other factors."

Pollard fi ds that electrics are pretty reliable, consi i ring that they're subjected to high-press washing on a regular basis, but he has nob that after a few years connec tors, such those on the starter motor,

become co aed. "They're only pinched on the cable so we clean them and solder them up," he says

Using N ille Charrold steel bodies and Edbro front end tipping gear gives the sixwheelers a • tonne payload: with a range of jobs fuel co umption is variable.

Pollard di s not believe in the under-floor

tipping concept: "By the time extra strengt: has been added to the body and chassis i doesn't save much in weight and I've neve been happy with the thought of twin rams, he explains. "As a workhorse I would give th 3000 Series eight out of ten but it does ric shine as well on driver comforts. We pay tha bit extra for a decent seat but the cab can be bit tight for a big man. There isn't much root in the footwell," he adds.

Pollard keeps an eye on prices and says h can buy the 3000 Series for less than he wouli have to pay for its competitors. When it's tim for disposal he sells them easily to privet buyers: "We got £6,000 recently

A for a B-reg it) ....-.-"=" '""' Gardner-pow _ ered eight-wheel

l3 I er".

He reckons that Foden's parts prices are good and proprietary parts can be obtained outside of the Foden network. The main dealers provide a good backup service but because of the diversity of component options they can't carry everything in stock all of the time. His most serious complaint is that Foden doesn't always notify operators of modifications it has made to overcome small problems, but this did not stop him ordering three new six-wheelers and an eight-wheeler on the very day we spoke to him.

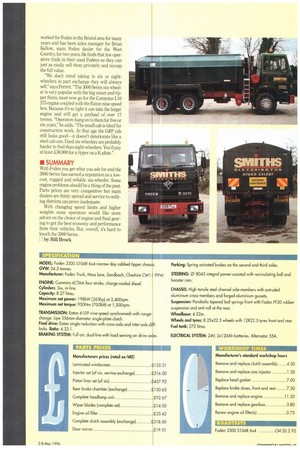

CW Griffiths and Sons is based at Old Radnor on the Welsh borders. Clarence Griffiths started the business in 1959. Now, aged 66, he still takes an interest but son Paul oversees the day-to-day running of the company and also finds time to drive himself.

He runs five Fodens and four Leyland Dafs on contract with Nash Rocks, delivering building and road-making materials over a 30-mile radius. All the vehicles are 6x4s which, he says, are best suited to narrow roads and difficult access to many of the building sites and farms in the area. Four of his Fodens are 3000 Series but while earlier models were specified with the Cummins 275 C-Series the latest one, bought in March, is fitted with a Euro-1 Cummins L10 325.

"We had the second narrow-cab 3000 Series off the line," he says. "It was registered in August 1991 and has covered 450,000 miles. The C-Series had its problems: warped blocks allowed number five cylinder liner to drop and

caused the head gasket to leak. We had to replace a few engines on different trucks but Cumrnins at West Bromwich stood by us. We need the power to work in the hills and on difficult sites. With the extra tonne of payload at 26 tonnes we decided to go for the bigger engine this time which has the advantage of being fitted with a Jake brake. It's good on journey times but fuel consumption is not so good. The C-Series gives us 10mpg and we only get eight with the L10, which is heavier and cost us an extra £6,500.

"To keep life simple all the trucks are spec ified with nine-speed transmissions," he adds. "I don't like the cable linkage. It has a vague feel and needs replacing after three to four years, The parts cost £250 and it's expensive in time as well. The chassis is very rugged and the driveline is second to none. The rubber suspension gives us five years' maintenance-free operation. It tends to scuff tyres more than a steel suspension and it doesn't offer the same articulation as we get with the Leylands but it's pretty good on site.

"I preferred the manual adjusters for the brakes," he says. "We were kept more aware of how quickly they were wearing. Electrics are not bad but can suffer from damp. There's no alternative to steel bumpers for site work; they carry the headlight so if they get bent they need to he straightened at the time. Although mirrors rattle and bits break off inside I like the cab. It's big enough and we have air suspended seats in all of them."

Griffiths likes to keep his vehicles for between five and seven years. He finds they are easy to resell and he gets a better price for the Fodens than he does for the Leylands Dafs.

"Foden's new vehicle prices are among the cheapest around and parts are about one third of what we pay for our Leylands," he reports. "But for me Foden has a real problem with maintenance backup. Our nearest main dealer is 90 miles away at Swansea and they only offer a twice-weekly parts delivery service. We carry some stock but if something unexpected lets us down the vehicle could be off the road for days."

Independent London dealer Chris Hodge has a stock of about 600 vehicles on his four sites at Blackwall Lane, Greenwich but when we talked to him, there were no Foden 3000s among them. "We are looking at low volume for salts of new models," he says. "A lot of them go to the large fleets such as Wimpey and ARC where they may work for up to 10 years before coming on to the used truck market. I haven't seen or heard of any decent examples being offered at auction.

"We get a lot of enquiries for sixwheelers in the London area and we would have no trouble selling Foden 3000 6x4s if we were offered any. It has a good spec which offers a choice of engines and transmissions. The rubber suspension does not suit everyone but it's reliable and overall the truck is light, robust and cheap to repair."

Ian Perrett has worked for Foden in the Bristol area for many years and has been sales manager for Brian Kellow, main Foden dealer for the West Country, for two years. He finds that few operators trade in their used Fodens as they can just as easily sell them privately and recoup the full value.

"We don't mind taking in six or eightwheelers in part exchange they will always sell," says Perrett "The 3000 Series six-wheeler is very popular with the big mixer and tipper fleets: most now go for the Cummins LIO 275 engine coupled with the Eaton nine-speed box. Because it's so light it can take the larger engine and still get a payload of over 17 tonnes. "Operators hang on to them for five or six years," he adds. "The small cab is ideal for construction work. At that age the GRP cab still looks good—it doesn't deteriorate like a steel cab can. Used six-wheelers are probably harder to find than eight-wheelers. You'd pay at least £30,000 for a tipper on a K-plate."

II SUMMARY

With Foden you get what you ask for and the 3000 Series has earned a reputation as a lowcost, rugged and reliable six-wheeler. Some engine problems should be a thing of the past. Parts prices are very competitive but main dealers are thinly spread and service to outlying districts can prove inadequate.

With changing speed limits and higher weights some operators would like more advice on the choice of engine and final gearing to get the best economy and performance from their vehicles. But, overall, it's hard to knock the 3000 Series.

17, by Bill Brock