GREASED

Page 31

Page 32

Page 33

Page 34

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

LIGHTNING

Exceptional performance, a highly competitive price and a top-of-the-class payload will make ERF's E14.465 a tempting prospect for the discerning owner-driver. • How fast do you want to go? In theory, about the only restriction on ERF's E14.465 flagship seems to be its driver's desire to avoid speeding fines.

Its charge-cooled Cummins engine is designated E465: in fact it develops a 'mere' 429 horses (320kW) at just 1,900rpm. If left unchecked the big 14-litre lump would be capable of propelling a fully freighted E14 along at more than 80mph (130km/h). In fact ERF has specified a road speed limiter as standard, keeping one jump ahead of the proposed legislation which is due to introduce mandatory limiters on all new vehicles over 7.5 tonnes from next April.

The problem is, while few laden vehicles are capable of speeding uphill, even the most gutless gaffer's motor will need to be restrained running downhill if the gradient is long enough and steep enough. So, in the wake of underrun bumpers, side guards and spray suppression equipment, hauliers are once again facing politically motivated legislation which will boost their vehicle costs without solving the problem.

If we were evaluating a sports car this would be praise indeed. But do you really need this level of performance from a 38-tonne artic? Fire-breathing tractors certainly make life easier for the driver, but given the congested state of Britain's motorways, all the power in the world isn't likely to shave much time off a run from Sandhach to Stevenage.

• DRIVELINE

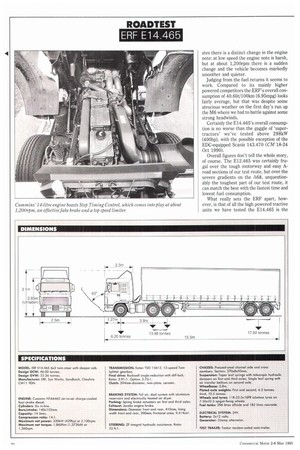

Despite a brief appearance at the NEC Motor Show last September, Cummins' fully electronic fuel injection CELECT system is not expected to join its UK range yet awhile. But the E465 does have Cummins' Step Timing Control (STC), which is now standard on selected high-power engines.

For a system designed to optimise performance and improve fuel efficiency, the STC theory is pretty straightforward. A hydraulic tappet mounted at the top of a top stop injector controls the fuel-injection timing to suit the load on the engine.

During start up, idling and light-load operation a low-pressure' signal from the fuel pump causes the control valve to pass sump oil to the STC tappet, which advances the injection timing. This allows a longer period for combustion, generating the higher cylinder pressures which benefit cold weather idling, cut down white smoke, improve light load fuel economy and reduce injector carbonisation.

At medium to high engine loads the fuel injection timing returns to normal, avoiding the build-up of extreme internal cylinder pressures. The system works hydromechanically so there is no need for extra gears, cam followers, or electrical connections.

When STC oper ates there is a distinct change in the engine note: at low speed the engine note is harsh, but at about 1,200rpm there is a sudden change and the vehicle becomes markedly smoother and quieter.

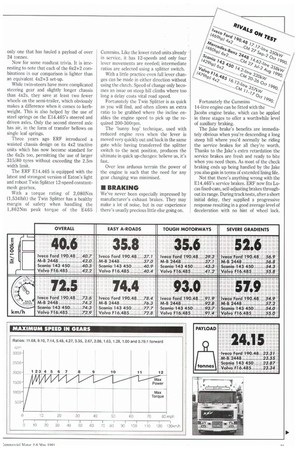

Judging from the fuel returns it seems to work. Compared to its mainly higher powered competitors the ERF's overall consumption of 40.6lit1100km (6.95mpg) looks fairly average, but that was despite some atrocious weather on the first day's run up the M6 where we had to battle against some strong headwinds.

Certainly the E14.465's overall consumption is no worse than the gaggle of 'supertractors' we've tested above 298kW (400hp), with the possible exception of the EDC-equipped Scania 143.470 (CM 18-24 Oct 1990).

Overall figures don't tell the whole story, of course. The E12.465 was certainly frugal over the tough motorway and easy Aroad sections of our test route, but over the severe gradients on the A68, unquestionably the toughest part of our test route, it can match the best with the fastest time and lowest fuel consumption.

What really sets the ERF apart, however, is that of all the high powered tractive units we have tested the E14.465 is the only one that has hauled a payload of over 24 tonnes.

Now for some roadtest trivia. It is interesting to note that each of the 6x2+2 combinations in our comparison is lighter than an equivalent 4x2+3 set-up.

While twin-steers have more complicated steering gear and slightly longer chassis than 4x2s, they save at least two fewer wheels on the semi-trailer, which obviously makes a difference when it comes to kerbweight. This is also helped by the use of steel springs on the E14.465's steered and driven axles. Only the second steered axle has air, in the form of transfer bellows on single leaf springs.

Three years ago ERF introduced a waisted chassis design on its 4x2 tractive units which has now become standard for the 6x2s too, permitting the use of larger 315/80 tyres without exceeding the 2.5m width limit.

The ERF E14.465 is equipped with the latest and strongest version of Eaton's light and robust Twin Splitter 12-speed constantmesh gearbox.

With a torque rating of 2,080Nm (1,534lbft) the Twin Splitter has a healthy margin of safety when handling the 1,862Nm peak torque of the E465 Cummins. Like the lower rated units already in service, it has 12-speeds and only four lever movements are needed; intermediate ratios are selected using a splitter switch, With a little practice even full lever changes can be made in either direction without using the clutch. Speed of change only becomes an issue on steep hill climbs where too long a delay costs vital road speed.

Fortunately the Twin Splitter is as quick as you will find, and often allows an extra ratio to be grabbed where the incline enables the engine speed to pick up the required 200-300rpm.

The 'bunny hop technique, used with reduced engine revs when the lever is moved very quickly out and back in the same gate while having transferred the splitter switch to the next position, produces the ultimate in quick up-changes: believe us, it's fast.

Over less arduous terrain the power of the engine is such that the need for any gear changing was minimised.

• BRAKING

We've never been especially impressed by manufacturer's exhaust brakes. They may make a lot of noise, but in our experience there's usually precious little else going on. Fortunately the Cummins 14-litre engine can be fitted with the Jacobs engine brake, which can be applied in three stages to offer a worthwhile level of auxiliary braking.

The Jake brake's benefits are immediately obvious when you're descending a long steep hill where you'd normally be riding the service brakes for all they're worth. Thanks to the Jake's extra retardation the service brakes are fresh and ready to bite when you need them. As most of the check braking ends up being handled by the Jake you also gain in terms of extended lining life.

Not that there's anything wrong with the E14.465's service brakes. ERF now fits Lucas fixed-cam, self-adjusting brakes throughout its range. During track tests, after a short initial delay, they supplied a progressive response resulting in a good average level of deceleration with no hint of wheel lock.

• CAB COMFORT

From the outside ERF's steel-framed/SMCpanelled SP4B single-bunk sleeper cab looks much as it did when the E Series was unveiled back in 1986. Out on the road, however, interior noise levels are noticeably lower.

ERF has added deeper inner-wing valances; these and the chassis-mounted rear noise reduction shield are the total extent of engine encapsulation. Most of the noise reduction has been achieved with the use of a 35% larger exhaust silencer. Simple, but effective.

Cab access is via three wide steps but these have a smooth surface which does not offer too much grip.

The modern dog-legged dashboard incorporates a clear instrument display housing an electrically driven instrument pack. The electrical system has been revised using printed circuit boards: virtually all electrical functions are now protected by a new design of mini circuit breakers.

A comfortable high-backed air-suspended driver's seat is easily adjusted for individual preference. The single bunk is mounted relatively high, leaving plenty of stowage space below it in two compartments behind the seats.

Three-axle tractors always seem to be comfortable mounts and the E14.465 twinsteer is no exception. It provides a stable ride with little sign of pitch and only slightly more roll. The power-assisted steering makes light work of driving, even when turning on full lock, but offers plenty of feel, leaving you in no doubt as to where the front wheels are pointing.

The SP4 cab may not quite have the same aura as a big Scania or Volvo but the interior is comfortable and the practical two-tone brown colour scheme shouldn't show the dirt.

• SUMMARY

Whether high-powered trucks like the E14.465 can be justified financially is a moot point, but they certainly make life a lot easier for the driver.

On paper the ERF E14.465 looks like a good buy, either as a 4x2 or a twin steer: the difference in price is £5,000-7,000. As a six-wheeler it offers exceptional value, even though the specifications may not be directly comparable.

Everybody knows ERF offers competitive prices, and the E14.465 twin-steer actually costs less than some other manufacturer's

high powered 4x2s. In our sample it is almost 28% cheaper than the heavier Iveco

Ford 260.48 tag-axle Turbostar; £.12,000 less than the Mercedes-Benz 2448; £11,000 less than the Scania 143 450, and nigh on £10,000 less than the Volvo F16.

To be fair, however, when you start matching like for like these price differen tials do start to close as the ERF does not include many of the extras that most of its direct competitors offer as standard no tably an anti-lock braking system and full air suspension. But it meets two of the main criteria of a premium tractor: it is quiet and it is comfortable.

What's more important, in these recession-hit days, its payload capacity is hard to beat. Combine that with excellent journey times and it has the potential for praiseworthy productivity, particularly if its fuel consumption fulfils its promise under less adverse operating conditions.

ERF has assembled a package using proprietary components that matches the best in Europe, at substantially less expense. If our test is anything to go by those operators who have previously bought Swedish vehicles would do well to try the truck from Sandbach.

El by Bill Brock