199.—A New Gasket for the Valve Caps of the Tylor Engine.

Page 30

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

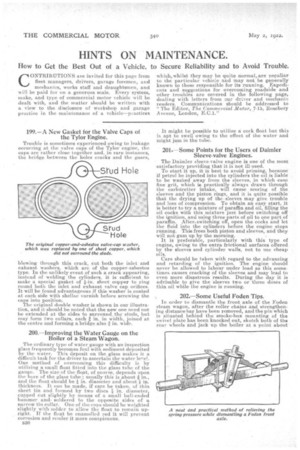

Trouble is sometimes experienced owing to leakage occurring at the valve caps of the Tylor engine, the caps are rather close together and, in rare instances, the bridge between the holes cracks and the gases,

blowing through this crack, cut both the inlet and exhaust washers, which are of the copper-asbestos type. In the unlikely event of such a crack appearing, instead of welding the cylinders, it is sufficient to make a special gasket of 4-in. sheet copper to ring round both the inlet and exhaust valve cap orifices. It will be found advantageous if this washer is coated at each. side with shellac varnish before screwing the caps into position. The original double washer is shown in our illustration, and it should be noted that the new one need not be extended at the sides to surround; the studs, but may form two collars, each .R in. in width, joined at the centre and forming a bridge also in. wide.

200.—Improving the Water Gauge on the Boiler of a Steam Wagon.

• The ordinary type of water gauge with an inspection glass frequently becomes foul with sediment deposited by the water. Tins deposit on the glass makes it a difficult task for the driver to ascertain the water level. One method of overcoming this difficulty is by utilizing a small float fitted into the glass tube of the gauge. The size of the flog, of course, depends upon the bore of the glass tube.; usually this is About in., and the float should be ir in. diameter and about f, thickness. It can be made, if care be taken, of thin sheet tin and formed by two discs in. diameter, cupped cut slightly by means of a small ball-ended hammer and, sold•ered to the opposite sides of a narrow tin collar, One of the eons should be weighted slightly with solder to allow the float to remain upright. If the float be enamelled red it will prevent corrosion and render it more conspicuous.

B30 It might be possible to utilize a cork float but this is apt to swell owing to the effect of the water and might jam in the tube.

201. Some Points for the Users of Daimler Sleeve-valve Engines.

The Daimler .sleeve-valve engine is one of the most satisfactory providing that it is not ill-used. To start it up, it is best to avoid priming, because if petrol be injected into the cylinders the oil is liable to be washed away from the sleeves, in which case fine grit, which is practically always drawn through the carburetter intake, will cause scoring of the sleeves and the piston rings, and it is quite possible that the drying up of the sleeves may give trouble and loss of compression. To obtain an easy start, it is better to try a mixture of paraffin and oil, filling the oil cocks with this mixture just before switching off the ignition, and using three parts of oil to one part of paraffin. After. switching off, open the cocks and let the fluid into the cylinders before the engine stops running. This frees both piston and sleeves, and they will not gum up by the morning.

It is preferable, particularly with this type of engine, owing to the extra frictional surfaces offered by the sleeves and cylinder walls, not to use cheap oils.

Care should be taken with regard to the advancing and retarding of the ignition. The engine should never be allowed to labour under load as this sometimes causes cracking of the sleeves and may lead to even more disastrous 'results. During the day it is advisable to give the sleeves two or three doses of thin oil while the engine is running.

202.—Some Useful Foden Tips.

In order to dismantle the front axle of the Foden steam wagon, after the roller chains and strengthening distance bar have been removed, and the pin which is situated behind the 'smoke-box mounting of the swivel plate has been knocked out, skotch both of the rear wheels and jack up the boiler at a -point about ii ft. from the swivel, and to ,an additional height of about 8 ins. The front wheels and axle can 1113W -be withdrawn from under the boiler. The laminated spring, which is fitted between the swivel and the axle, is constantly compressed, and in order to take it off the device illustrated should be employed. It will be unnecessary to explain this in detail. In order to irnnrove the steering, if there are hard spots the swivel -should be bedded into its mounting and tested with " raddle," a file, scraper or emery cloth being used to remove the hard spots.

A great deal depends upon the way this job is done, and it is advisable to obtain a good bed across the swivel faee, and not on the radius.

After long service the front wheOs will show side

play. This can be cured by fitting steel washers between the collar and each wheel. Do not fit them between the wheel and the radius. The wheels are bushed, and these bushes can be knocked out by means of a mandril. They should be driven out from the inside, The .steering wheel itself should be examined for

play bylifting it. If there is undue lift, a brass washer can be fitted between the steering column collar and the chain roller casting. -The amount of backlash or lead should be about one quarter of a revolution of the steering wheel. Before reassembling the axle and steering, all oil grooves and oil holes should be cleaned out and well supplied with lubricant.