IN_ THE WORKSHOP.

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

Fittings and Methods Used by Some of Our Driver and Mechanic Readers.

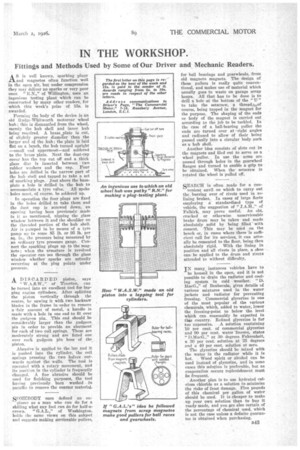

As is well known, sparking plugs and magnetos often function well in the open air, but under compression they may deliver no sparks or very poor ones. "R.N.," of Willington, uses an ingenious testing plant which can be constructed by many other readers, for which this week's prize of 15s. is awarded.

Forming the body of the device is an old Rudge-Whitworth motorcar wheel hid); this is dismantled from the wheel, merely the hub shell and inner hub being required. A brass plate is cut, of slightly greater diameter than the larger end of the hub ; the plate is laid flat on a bench, the hub turned upright —small end uppermost—and soldered to the brass plate. Next the dust-cap cover has the top cut off and a thick glass disc is inserted between two. rubber washers and the cap. Four holes are drilled in the narrow part of the hub shell and tapped to take a set of sparking plugs. J'ust above the baseplate a hole is drilled in the hub to accommodate a tyre valve. All spoke holes must, of course, be soldered up.

In operation the four plugs are fixed in the holes drilled to take them and the dust cap is screwed down, an opening having been previously Made in it as mentioned, nipping the glass

• window between it and the shoulder on the threaded portion of the hub shell. Air is pumped in by means of a tyre pump up to some 85 lb. or 95 lb. per sq. in., the pressure being measured by an ordinary tyre pressure gauge. Connect the sparking plugs up to the magneto; when the armature is revolved the operator can see through the glass window whether sparks are actually occurring at the ping points under .pressure.

A DISCARDED piston, says "W.A.S.W.," of Tiverton. can be turned into an excellent tool for lapping engine cylinders. After splitting the piston vertically through the centre, by sawing it with two hacksaw blades in the frame in order to remove a -fair amount of metal, a handle is made with a hole in one end to fit over the gudgeon pin. This end should be considerably larger than the gudgeon pin in order to provide an abutment for each of two coil springs. These are moderately strong and are fitted one over each gudgeon pin boss • of the piston.

Abrasive is applied to the lap and it is pushed into the cylinder, the coil springs pressing the two halves outwards against the walls. The tool is operated with a rotary movement, and its position in the cylinder is frequently changed. A fine abrasive should be used for finishing purposes, the tool • having previously been washed in paraffin to remove the coarser material.

SOMEBODY once defined an engineer as a man who can do for a shilling what any fool can do for half-a crown. " G.A.L.," of Washington, holds the same views an this subject and suggests making serviceable pullers, for ball bearings and gearwheels. from old magneto magnets. The design of these pullers is really quite conventional, and makes use of material which usually goes to waste on garage scrap heaps. All that has to be done is to drill a hole at the bottom of the "

to take the setscrew, a threadAr,,of course, being tapped in the magnet for the purpose. The shaping of the ends or body of the magnet is carried out according to the job to be tackled. In the case of a ball-bearing puller the ends are turned over at ,right angles and radiused to allow of their being passed easily into a circular body such as a hub shell.

Another idea consists of slots cut in the magnets and filed out to serve as a wheel puller. In use the arms are passed through holes in the gearwheel flanges and turned to enable a grip to be obtained. When the setscrew is rotated the wheel is pulled off.

SEARCH is often made for a con

venient anvil on which to carry out the, burring over of rivets used in relining brakes. In cases of large fleets employing a standardized type of vehicle, the suggestion of " j.A.H.," of Falkirk, may prove useful. .An old, cracked or otherwise unserviceable brake drum may be taken and made absolutely solid by -being filledwith cement. This may be used on the bench or, in cases where there is sufficient call for its services, it can actually be cemented to the floor, being then absolutely rigid. With the lining in position and all rivets in place, a shoe can be applied to the drum and rivets attended to without difficulty.

IN many, instances vehicles have to be housed in the open, and it is not Possible to drain the radiator and cooling system in cold weather. "D. MacG.," of Benbecula, gives details of various mixtures used in the water jackets and radiator for preventing freezing. Commercial glycerine is one of the most popular of the various chemicals, which, added to water, lower the freezing-point to below the level which can reasonably be expected in this country. Refined glycerine is far too expensive. A solution containing 10 per cent. of commercial glycerine and 90 per cent. water freezes, states " D.hiacG.," at 30 degrees Fahrenheit, a 30 per cent, solution at 25 degrees and a 40 per cent. solution at zero.

The glycerine should be mixed with the water in the radiator while it is hot. Wood spirit or alcohol can be used instead of glycerine, and in some cases bbie solution is preferable, but as evaporation occurs re,plenishment must be frequent.

Another plan is to use hydrated calcium chloride as a solution to minimize the risks of frost damage. Five pounds of this chemical per gallon of water should be used. It is cheaper to make up your own solution than to buy it ready made, and you are also certain of the percentage of chemical used, which is not the case unless a definite guarantee is obtained when purchasing.