For DRIVERS, MECHANICS & FOREMEN.

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS is paid to the sender of any letter which we publish on this page, and an. EXTRA FIVE SHILLINGS to the sender of the one which we select as being the best each week. All notes are edited before being published. Mention your employer's name, in. confidence, as eoidenc,e of good faith. Address, D., Al. and F., "The pornmercial Motor," 7-15, Bosebery Avenue, London, E.G. 1.

Lamps Alight.

On Saturday, March 6th, light your lamps at 6.17 in London, 6.8 in Edinburgh, 6.6 in Newcastle, 6.18 in Liverpool, 6.38 in Birmingham, 6.27 in Bristol, and 7.4 in Dublin.

A Broken Stud Shaft.

The sender of the following communication has been awarded the extra payment of 5s. this week.

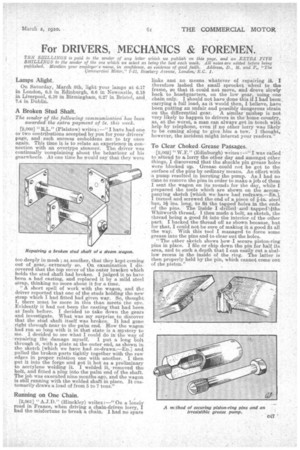

[2,060] " R.L." (Plaistow) writes :—" I have had one or two contributions accepted by you for your drivers' page, and such success emboldens me to try once again. This time it is to relate an experience in connection with an overtype steamer. The driver was continually complaining about the behaviour of his gearwheels. At one time he would say that they were too deeply in mesh ; at another, that they kept coming out of gear, orvnearly so. On examination I dis• covered that the top cover of the outer bracket which holds the stud shaft had broken. I judged it to have been a bad casting, and replaced it by a mild steel strap, thinking no more about it for a time.

"A short spell of work with the wagon, and the driver reported that one of the studs holding the new strap which I had fitted had given way. So, thought I, there must be more in this than meets the eye. Evidently it had not been the casting that had been at fault before. I decided to take down the gears and investigate. What was ray surprise to discover that the stud shaft itself was broken. It had gone right through near to the palm end. How the wagon had run so long with it in that state is a mystery to ine. I decided to see what I could do in the way of repairing the damage myself. I put a long bolt through it, with a plate at the outer end, as shown in the sketch [which we have had re-drawn.—En.] and, pulled the broken parts tightly together with the, raw edges in proper relation one with another. I then put it into the forge and got it hot as a preliminary to acetylene welding it. I welded it, removed the bolt, and fitted a plug into the palm end of the shaft. The job was executed nine months ago, and the wagon is still running with the welded shaft in place. It cue-. tomarily draws a load of from 6 to 7 tons.

Running on One Chain.

[2,061] " A.J.D." (Hinckley) writes :—" On a lonely road in France, when driving a chain-driven lorry, I had the misfortune to break a chain. I had no spare links and no means whatever of repairing it. I therefore lashed the small sprocket -wheel to the frame, so that it could not move, and drove slowly back to headquarters, on the low gear, using one chain only. I should not have done this if I had been carrying a full load, as it would then, I believe, have been putting an unfair and possibly dangerous strain on the differential gear. .A similar mishap is not very likely to happen to drivers in the home country, as, at the worst, a man can always get in touch with help by telephone, even if no other lorry wag likely to be coming along to give him a tow. I thought, however, the incident might interest your readers."

To Clear Choked Grease Passages.

[2,O62j "W.F." (Edinburgh) writes :—" I was called to attend to a. lorry the other day and amongst other things, I discovered that the shackle pin grease holes were blocked up. Grease could not be got to the surface of the pins by ordinary means. An effort with a pump resulted in bursting the pump. As :I had no time to remove the pins in order to make a job of them I sent the wagon on its rounds for the day, while I prepared the tools which are shown on the accompanying sketch [which we have had redrawn.—Enl. I turned and screwed the end of a piece of i-ina steel bar, ins, long, to fit the tapped holes in the ends of the pins. The inside I drilled and tappecllths Whitworth thread. I then made a bolt, as sketch, the thread being a good fit into the interior, of the other part. I backed the 'thread off as shown because, but for that, I could not be sure of making it a good fit all the way. With this tool I managed to force some grease into the pins and to clear out the holes. "The other sketch shows how secure piston-ring pins in place. I file or chip down the pin for half its area, and to such a depth that I can easily cut a shallow recess in the inside of the ring. The latter is then properly held by the pin, which cannot come out of the piston."