Case-hardening and Annealing Furnaces.

Page 7

Page 8

If you've noticed an error in this article please click here to report it so we can fix it.

Being Notes Made on the Occasion of a Recent Visit to the Premises of Manchester Furnaces, Ltd. They will Serve to Indicate to the User Something of the Processes which are Nowadays Considered Necessary in the Heat Treatment of Steel and Other Metals.

It seems a far cry now to those days of seven or eight gears ago, when, in the course of a series of articles dealing with motorvehicle manufacture, we drew attention to the Methods adopted for the various heat treatments necessary for steel used in construction. At that time, although much was known about steel and its treatment, the methods in use by not a few of our principal manufacturers, to say the least of it, did not correspond with the best ascertained means. The heat treatment of steel, for success and uniform results, depends very considerably upon scientific working, and on operations conducted at temperatures which must be kept within fairly fine limits.

The Personal Element Once a Feature.

Even so short a while ago as that indicated, a great deal of the work was performed by a blacksmith with a, special bent for it ; as a rule, one particular hearth in the smithy was set aside for the work, and the success, or otherwise, was dependent entirely on what we may term the personal element. The actual colour of the metal was taken as a sufficient guide to its temperature, and uniform results were likely to be lacking if only for the reason that the physical condition of the operator might determine his views as to the correct colour : In many works of small capacity such methods will even now be found in operation, but in the case of any firm wishing to continue successfully, these rule of thumb tactics will have to be entirely discarded.

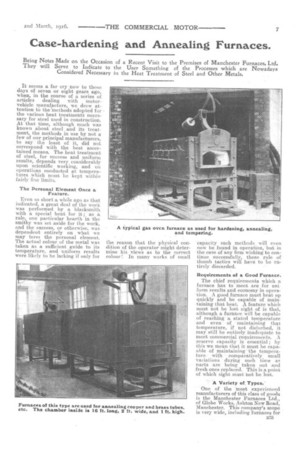

Requirements of a Good Furnace.

The chief requirements which a furnace has to meet are for urn form results and economy in opera'tion. A good furnace must heat up quickly and be capable of maintaining that heat. A feature which must not be lost sight of is that, although a furnace will be capable of reaching a stated temperature and even • of • rffaintaining that temperature, if not disturbed, it may still be entirely inadeqUate to meet commercial requirements. A reserve capacity is essential ; by this we mean that it must be capaable of maintaining the temperature with ,comparatively small variations during such time as Parts are being taken out and fresh ones-re-placed, This is a point of which sight must hot be lost.

• A Variety of Types.

One of the 'most experienced manufacturers of this 'class of goods is the Manchester Furnaces Ltd. of Globe Works, Ashton New Road, Manchester. This company's scope. is very wide, including furnaces for all kinds of work, for forging, casehardening and annealing of all kinds of steel, as well as for the heat treatment of brass, nickel, and the rarer metals. Types are marketed which utilize solid, liquid, or gaseous fuels. In the course of a

stroll round the works, we saw sonic made to burn coal, coke, producer gas, town gas, and oil. The question arises as to the need for all these varieties. The answer is that local conditions very considerably affect the desirability of using either one fuel or another. Of course, economy is a great point, and if cost of fuel only had to be considered, it will very often be found that coal is likely to be the first choice, or possibly coke ; on the other hand, the use of gas or of oil considerably simplifies matters ; the extra labour involved in carting is dispensed with, and these fuels are also worthy of special consideration where economy of space is important. This is a matter, of course, where each decision must be made on the merits of the case. There is another point of view also, concerning the peculiar adaptability of gas and oil fuel for special kinds of work. For example, where the even distribution of heat is all important, there is no doubt whatever that gas takes first place. In round figures the merits of gas, oil and coal in this respect are in a ratio of 4, 2, and 1.

Special Features of the Manchester Furnace.

A special feature of the furnaces made by this company is the uniformity of temperature maintained from front to back. This is due to the arrangement of flues whereby n313 the fire is built under the floor, and the burning gases are then taken up both sides of the furnace ; they then travel to the front, making their exit at the sides just inside the door, and thence by way of flues underneath, to the chimney at the rear, The particular object of this is to prevent the entry of cold air near the door.

Munition Work: Making Six-inch

Shells.

Although, as stated, this company's products are particularly useful in connection with the treatment of automobile parts, it may be more interesting and topical at the present time if we devote some little space to a deseription of their special activities in regard to munition work.

One small order in course of execution on the occasion of our visit was for furnaces to heat 1600 6-in. shell billets a -week. It is interesting to note that the temperature of the furnaces neceSsary for this is 1300 degrees Cent. After the billet has been heated by this type of furnace, it is transferred to the hydraulic press and there forged ; it is . then returned to a Special type of furnace for heating One end so that the nose can be formed. (One of these we illustrate, and it is stated to he capable of fully heating one 6-in. shell per minute) After. boring and finishing, the shells are as a rule subjected to a japanning process, and here again, the assistance of Manchester Furnaces Ltd. is called upon to provide the necessary furnaces.

In fact; there is hardly any process of engineering science involving the application of heat for which the company has not got a suitable furnace.

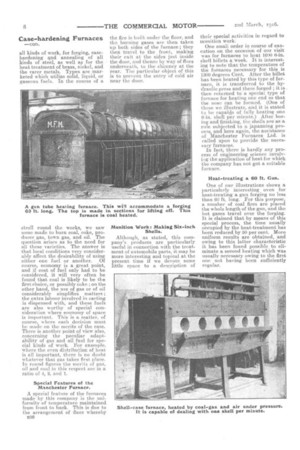

Heat-treating a 60 ft. Gun.

One of our illustrations shows a particularly interesting oven for heat-treating a gun forging no less than 60 ft, long. For this purpose, a number of coal fires are placed the whole length of the gun, and the hot gases travel over the forging. It is claimed that by means of this special process, the time usually occupied by the heat-treatment has been reduced by 50 per cent. More uniform results are obtained, and owing to this latter characteristic it has been found possible to eliminate a second heating which was usually necessary owing to the first one not haying been sufficiently regular.