THE CLOTHES SHOW

Page 51

Page 52

Page 53

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

Operators in the hanging garment sector need rails in their trailers. But, as Tim Maughan finds, they also need to invest in warehouse technology it they are to thrive.

DTS LOGISTICS

Aside from tap water and the air we breathe, road transport operators haul just about everything we need. HGVs carry food, fuel, automotive parts and construction materials.They also shift clothes. Socks and underwear can be easily palletised, but other items of clothing require more specialised treatment: they need to be handled by hanging garment experts.

One of them — and there are only a handful in the country — is Mike Daly, MD of DTS Logistics.The firm turns over £40m a year; impressive by any standards, but all the more notable when you consider Daly is self-made. He has not risen through the family ranks or inherited a depot, trucks, or customer base.

He bought his first CV in 1979,a MercedesBenz panel van when he saw a gap in the market and filled it."Students at Enfield Polytechnic wanted light items moved, as well as heavier items like wardrobes. I bought the little van. and charged by the hour. People didn't pack their clothes. so I put a metal bar at the front of the van. It was all weekend and evening work."

Daly then started to handle props and clothing for Cats, the stage show.The rail in his van was coming into its own."I used it to hang the costumes," he remembers, in 1980 he was approached by a clothing manufacturer,fitted extra bars into his van, and was soon dropping garments to a C-Ar A RDC."The site had 50 loading bays, which was quite advanced for the time.

"I knew this was the business I would go into because I thought clothing was recession proof. From that day on,! started canvassing for work in the hanging garment industry."

Yearly growth

Since it was founded. DTS has enjoyed year-onyear growth of 10-20%. Last year, Daly was approached by Clipper Group Holdings. Chief executive Steve Parkin believed there was a market for medium-size operators, working in niche markets.A commercial merger took place in September 2004.

Daly believes firms go one of three ways: they are passed on to the next generation of the family; they become "old and crippled"; or they are rejuvenated through an "exit strategy".The last option applies to DTS.

Clipper Logistics (part of Clipper Group Holdings) amalgamated its fashion transport services with DTS. CGH turns over £82m; nearly half of it generated by DTS. The merger has benefited both parties, says 3aly."We are making significant economies of cale through insurance, fuel purchasing, nobile phone deals and so on."

As time has passed, this sector has under;one changes. DTS HGVs used to collect suits 'tom UK manufacturers, Now, these garments ire picked up from airport freight handling igents. Increasingly, other operators bring ;lothes to DTS sites.

With warehouses,many fleets claim to have ;omplete national coverage, but sometimes .)bvious geographical gaps appear in their ietworks. Not here. Daly rattles off a list of his )ases.The Enfield site has 23225m2 of hanging arment accommodation.At Milton Keynes the depot we visit) there are 18,000m2, split )etween two sites,The base in north Mancheser is the largest, with 38.000m2 of space. 4dditionally, there are sites in Enfield, ■ Ieweastle-under-Lyme. Glasgow and Bath. These warehouses represent major invest ments, and have changed this sector's working methods.

"In the 1980s and '90s,we used to take clothes to retailers' ADCs. But we reinvented this model. Now we work direct with the retailers, delivering directly to their stores, We are their RDCs."

Daly produces his first company brochure, which hails from 1982. In 2005, it has a certain aged charm about it.

But in its time it was a vital tool in getting the DTS message across in the marketplace.

Market changes

He has kept abreast of market changes. In the 1980s, many garments were made in Portugal, Greece, Malta and Cyprus. When package holidays to these destinations rocketed, the locals switched jobs to the hotel and catering business.The clothing factories were stripped of their personnel — and that impacted on Daly.

He says: The cut, make and trim factories closed down, and the work moved to Turkey, Romania, and Morocco. In the 1990s,we used to bring zips and shoulder pads to the UK.We had 30 trucks on international work,they would go out on a Sunday evening, and be back two weeks later on the Thursday."

Daly's international drivers were paid competitive wages. "They deserved everything they got," he remembers. Nonetheless, overheads like these can be hard for a firm to absorb.

In addition, DTS' international operation was subjected to foreign competition. "Turkish operators got on the bandwagon. Compared with us, they had tiny overheads."

The Continental-bound fleet began to "peter out",he says. Rather than see it slowly die, Daly took action by selling its international division to Dutch company VH Logistics in 2001.

International factors affected the domestic operation too, because work in "primary" transport, that is, from manufacturer to retailer's RDC, dried up."I saw the process as evolution rather than revolution," he says.

In the mid to late 1990s, the big British retailers really started to notice him, and he won business with Liberty,Freemans, Debenhams and C&A.

At one time, DTS Logistics picked up clothes from 250 clothes factories in London's East End. These days, it's a question of collecting garments after they have been imported into the UK.

When you talk to Daly about his business, you immediately sense his energy and enthusiasm. Our conversation covers wider business issues, changing markets, and moves to operational matters. All the time,Daly speaks eloquently and with a sense of purpose.

DTS has 170 trucks: the firm also provides drivers for, and manages, a further 70 customers' HGVs. Stressing that his is an expanding company, he reveals that last year he secured contracts with retailers Harvey Nichols and New Look.

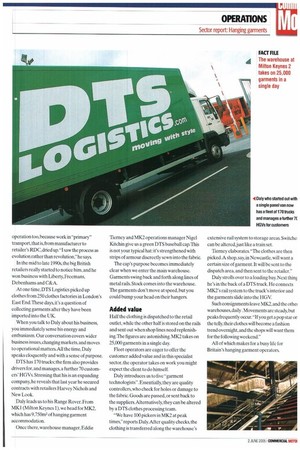

Daly leads us to his Range Rover. From MK1 (Milton Keynes 1), we head for MK2, which has 9,750m2 of hanging garment accommodation.

Once there, warehouse manager, Eddie Tierney and MK2 operations manager Nigel Kitchin give us a green DTS baseball cap.This is not your typical hat: it's strengthened with strips of armour discreetly sewn into the fabric.

The cap's purpose becomes immediately clear when we enter the main warehouse. Garments swing back and forth along lines of metal rails. Stock comes into the warehouse. The garments don't move at speed, but you could bump your head on their hangers.

Added value Half the clothing is dispatched to the retail outlet, while the other half is stored on the rails and sent out when shop lines need replenishing.The figures are astonishing. MK2 takes on 25,000 garments in a single day.

Fleet operators are eager to offer the customer added value and in this specialist sector, the operator takes on work you might expect the client to do himself Daly introduces us to five "garment technologists".Essentially, they are quality controllers, who check for holes or damage to the fabric. Goods are passed,or sent back to the suppliers. Alternatively, they can be altered by a DTS clothes processing team.

"We have 100 pickers in MK2 at peak times," reports Daly.After quality checks,the clothing is transferred along the warehouse's extensive rail system to storage areas. Switche: can be altered, just like a train set.

Tierney elaborates."The clothes are then picked. A shop, say, in Newcastle, will want a certain size of garment. It will be sent to the dispatch area, and then sent to the retailer."

Daly strolls over to a loading bay. Next thinE he's in the back of a DTS truck. He connects MK2's rail system to the truck's interior and the garments slide into the HGV.

Such consignments leave MK2, and the othei warehouses, daily. Movements are steady,but peaks frequently occur."If you get a pop star or the telly, their clothes will become a fashion trend overnight, and the shops will want them for the following weekend."

All of which makes for a busy life for Britain's hanging garment operators.

EXEL LOGISTICS Tibbet & Britten made its name in the fashion sector and first involved itself with hanging garments in 1958. Exel boughtTibbet & Britten in August 2004 and we visit its Daventry site.There, we meet Kim Sainsbury, pictured left. European development director, fashion and home, Mike Speakman, business unit director, and Neil Tooby.operations support manager.

"There is a need to understand this sector. We treat our clothing as we would fresh produce," says Sainsbury. "Our mission is to be the most creative and successful logistics partner, d elivcring new value, flexibility and tailored end-to-end supply chain solutions."

Like DTS, Exel recognises that success lies in pushing the boat out, over and above simply providing transport, "We want to reduce the amount of inventory the customer needs on his own premises," he adds. "House of Fraser in Dublin did not want stock kept on their premises because it took up too much space, so we built a warehouse to take it."

Garments come in a variety of sizes, and retailers take on different clothes. Multiply these with the myriad of retail outlets across the country, and you can see the immense scale of the operation.

Exel's hanging garment customers include Topshop, and Miss Selfridge. Many garments destined for UK shops are made in the Far East.

The firm uses its global muscle to oversee the entire transport process. Staff are placed near production centres, taking care of export paperwork, licences. and so on. Like Daly, Sainsbury says star appearances on television can have an instant effect. He calls this a "speed to market" phenomenon.

The classic image of the tee-shirt label, in which one size fits all, does not apply here, he adds. "One size does not fit all; different customers have different needs."

Take Exel's North African business. Morocco, although a major clothes producer, does not have the raw materials to make garments. To remedy this. Exel imports the produce, either with its own trucks or those of sub-contractors.

To perform operations like these you need the resources, quite literally, of an army. Exel fulfils this requirement with 111,000 personnel and an annual turnover of £6.3bn.

Mothercare contract

Sainsbury. Speakman and Toobey lead us to the main warehouse. Exel has recently signed a five year contract to deliver clothes for Mothercare 14% of the chain's clothing is hanging garments, the remainder is flatpacked.

The Daventry site has four storeys, and each level is connected with a powered rail system. Unmanned lines of garments traverse the rails. This is automation on an impressive scale. "Big lumps go out to the store, at seasonal changeovers," says Sainsbury.

Exel also fields its own quality controllers. Random checks are made on clothing provided by the more established suppliers. New suppliers' wares arc more rigorously scrutinised. Garments pass through a metal detector, which identifies pins and other unwanted items. After checking. stock faults are marked with red arrows.

"We also offer a repricing and relabelling service," says Toobey."And we also export clothes.We have socks fromTurkey that are bound for Kenya, Ghana, Qatar, and Latvia."

The Daventry unit serves 246 British stores. "We deliver to 140 stores a day. with each trucl delivering to two stores," says Toobey.The site also exports to 230 shops in 38 countries.

Sainsbury talks of company aims."AtTibbe & Britten I was managing director of the UK textile business, with responsibility for development.We want to develop existing business, or grow into new markets."

Other firms. such asTNT, Christian Salvesen and Gist, are involved in the hanging garments sector. "But nobody has the scale and the capabilities that we have," says Sainsbury.

-The way business is acquired is varied. There can be an invitation to tender, or there i! the opportunity to expand on existing work. Or Exel may identify new opportunities to work with customers."

The key to success is flexibility and quality o service."Different customers have different requirements.-saysToobey."There is a lot of emotion around clothes," reports Sainsbury. "You don't get that with a bottle of waterretail is about detail." •