SIMPLICITY .

Page 86

Page 87

Page 88

Page 91

If you've noticed an error in this article please click here to report it so we can fix it.

1111 THE SEGAS

SYSTEM

THE South Eastern Gas Board operates a fleet of more than 1,400 licensed vehicles over an area of 3,300 square miles in Kent, Surrey, Sussex and London south of the Thames. The fleet, which is over 90 per cent Ford, consists mainly of 350 cars and some 750 light vans of up to one ton capacity. The remainder are commercial vehicles with payloads of two tons and upwards. In general, gas is sold only where there are people and therefore the vehicles tend to operate in towns and villages throughout the area, with a large concentration in South London.

Supervision of the transport is maintained from a central transport office in South East London. The transport manager is responsible for all vehicles from purchase through maintenance, repairs, licensing and accident repairs—all their working life— including preparation and submission for sale. He is also responsible for technical advice on types and design of all vehicles as well as keeping officers up to date with regulations and legislation which affect them. He is responsible for the supply but not for the use of vehicles.

In the days before nationalization, each gas works, large or small, had its own transport section and workshop. By the progressive closing down of the smaller uneconomical works the need for these small maintenance units had to be balanced against the relatively high cost of running them, especially as there were no longer any items of works' plant needing "on the spot" attention. In many cases, also, the land has been either sold or converted to other uses.

The position today is that our workshops are reduced to five in number, located at large production works or at consumer service centres in heavily populated areas. These five transport workshops maintain approximately half the fleet. The others are serviced and repaired by selected contractors—widely scattered so that generally speaking no vehicle has to travel more than six miles for attention.

To supervise and check the work done by contractors, and also to afford liaison between them and the transport manager, a number of motor vehicle examiners are employed. These have staff status, with individual transport, and all have workshop background. They are at liberty to call at contractors' premises whenever they choose, and to spot-check or thoroughly examine any vehicle either on the road or undergoing maintenance. They are in daily telephone contact with head office and can get an immediate reply to any matters not within their jurisdiction or of an emergency nature. They are in fact workshop foremen without staff or premises apart from their own small regional office which they use as a centre. With the use of telephone answering machines, messages can always be left in their absence.

Servicing

Two standard types of servicing sheets (differently coloured) are used both in the Board's workshops and by contractors. They cover all types of servicing, and entries by mechanics are made against appropriate items by placing a tick in a box—each type of service having a vertical line of boxes, so that they can be checked by a quick glance. Provision is made for entering non-scheduled repair works—such, as drivers' complaints—and for Tapley brake readings on road tests. Each form is in duplicate and signed by the person in charge on completion—the top copy being sent to head office for scrutiny and filing.

Copies of servicing sheets are retained by foremen or motor vehicle examiners for local information. All forms, advices, etc„for each vehicle are kept in one pocket file at the central office so that its maintenance history is immediately available from first registration to disposal. One important factor of this system is that it conforms to the requirements of the Ministry of Transport by showing that correct maintenance has been carried out.

Paperwork to cover all servicing and repairs, including accidents, licences, etc„ is standardized whether a vehicle is repaired in our own workshops or outside and emphasis is laid on a rapid turnround of vehicles. Servicing of semi-trailers for articulated units is also covered by these sheets—there are two trailers per unit and these are brought in alternately with the tractive unit.

Latest techniques and equipment are used to deal with servicing which is carried out to makers recommendation but for set periods rather than on a mileage basis. The schedules for each type are, however, streamlined into two main groups–cars and light vans (which are similar mechanically) and heavy commercial vehicles which have chassis /cabs as a basis. Where differences occur in servicing periods these are always "closed up" to the shortest, so that some maintenance is done rather more often than recommended. This procedure has paid off in comparative freedom from breakdowns and a simplified servicing system.

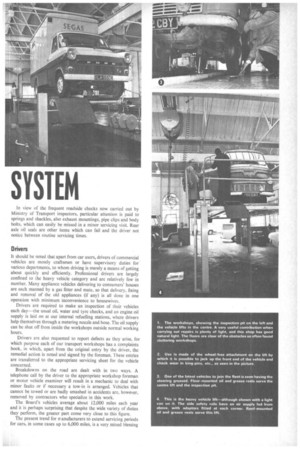

In view of the frequent roadside checks now carried out by Ministry of Transport inspectors, particular attention is paid to springs and shackles, also exhaust mountings, pipe clips and body bolts, which can easily be missed in a minor servicing visit. Rear axle oil seals are other items which can fail and the driver not notice between routine servicing times.

Drivers

It should be noted that apart from car users, drivers of commercial vehicles are mostly craftsmen or have supervisory duties for various departments, to whom driving is merely a means of getting about quickly and efficiently. Professional drivers are largely confined to the heavy vehicle category and are relatively few in number. Many appliance vehicles delivering to consumers' houses are each manned by a gas fitter and mate, so that delivery, fixing and removal of the old appliances (if any) is all done in one operation with minimum inconvenience to housewives.

Drivers are required to make an inspection of their vehicles each day—the usual oil, water and tyre checks, and an engine oil supply is laid on at our internal refuelling stations, where drivers help themselves through a metering nozzle and hose. The oil supply can be shut off from inside the workshops outside normal working hours.

Drivers are also requested to report defects as they arise, for which purpose each of our transport workshops has a complaints book, in which, apart from the original entry by the driver, the remedial action is noted and signed by the foreman. These entries are transferred to the appropriate servicing sheet for the vehicle concerned.

Breakdowns on the road are dealt with in two ways. A telephone call by the driver to the appropriate workshop foreman or motor vehicle examiner will result in a mechanic to deal with minor faults or if necessary a tow-in is arranged. Vehicles that cannot be towed or are badly smashed in accidents are, however, removed by contractors who specialize in this work.

The Board's vehicles average about 12,000 miles each year and it is perhaps surprising that despite the wide variety of duties they perform, the greater part come very close to this figure.

The present trend for rranufacturers to extend servicing periods for cars, in some cases up to 6,000 miles, is a very mixed blessing

for fleet owners, and is one aspect in which we depart from their, recommended schedules. This can in our own experience mean that they may not receive scheduled attention for periods of up to six months, by which time, brakes, clutches and the ignition systems are usually overdue for adjustment and sundry items like silencers are liable to shake loose. We have adopted an "intermediate" service for cars at two-monthly intervals which appears to meet the problem satisfactorily.

There are, of course, exceptions which cannot be disregarded; some light vans on messenger work, cars used by officers and representatives who cover the whole area of the Board in their duties, and some heavy tippers on trunking work—for these servicing schedules are specially drawn up to accommodate the extra heavy wear and tear. In the case of very low mileage vehicles, usually confined to specialist 'units and those on seasonal or emergency work, the standard servicing periods are followed, as it is so easy to overlook a vehicle that has spent a part of its time just waiting.

Modernization A programme of workshops' modernization was started a few years ago and is now completed. To get the best for our particular needs, a number of contemporary installations were examined and advice sought from experts in this field. One major decision made was to use electric vehicle hoists rather than pits. The Board inherited a number of pits in the workshops—some of which were no more than dirty holes in the ground and little used because of the unsatisfactory working conditions. The only means of lighting was usually a wandering lead lamp—at 240 VI A few pits, already sited in our remaining workshops, have been retained, but have been very much improved. Walls have been lined, sumps constructed and duck-board flooring fitted, shatterproof permanent lighting is provided, high-pressure lubricating equipment installed in proper bays with recesses for tools, etc, and proper oil draining facilities operated by compressed air are installed and have replaced the previous tins and jugs.

Apart from these, all our inspection bays are equipped with Laycock heavy, or light hoists—four-post models with plated tracks, some being special gallery types with facilities for working above and below simultaneously. They are provided with "wheelfree" elevating equipment as well as high pressure grease, oil, air and 110 V plug-in points for hand tools together with special lighting. A stock of fast moving items such as filters and gaskets, etc., is kept adjacent to each servicing hoist. Every mechanic, electrician and greaser is provided with a portable tool storage unit with lockable drawers and a smail work-top. In addition the men have fixed wall cupboards for items not in regular use and their personal "bits and pieces". An important point is that each man has his cupboard, portable unit and tools all painted in a distinctive individual colour—there is then no question of what belongs to whom!

Special tools are kept in a wired compound, clipped to labelled backboards and issued by the foreman on request against a signature.

Crypton engine tuning equipment is standard in all workshops and new Motorscope units are on order to replace Motormaster sets which have done good service. Our belief is that such apparatus is only as good as the person using it, and therefore advantage is taken of the special instruction courses provided by the suppliers.

Because each workshop undertakes both servicing and repairs, the staff at the larger ones work in teams which are changed around at intervals thus sharing "dirty" and "clean" work. An electrician, plus an assistant where necessary, is on call to any team and is otherwise engaged on routine work such as battery charging and checking electrical equipment. No major overhauls of electrical components are undertaken, these being changed by a service replacement scheme. Similarly, major mechanical cornponents—engines, gearboxes and rear axles, etc., are exchanged for reconditioned units as a general rule, but the wide variety of engines and components used on mobile plant are sometimes overhauled by our own staff when there is no reasonable alternative. No bodywork repairs are undertaken in our workshops, which means that by and large all accident repairs are carried out by contractors who specialize in this work.

Spares To keep capital invested in stores and spare parts to a controlled minimum, use is made of various factors' and manufacturers' agents to make daily delivery against demand.

Small stocks of fast moving consumables such as wiper blades, plugs, filters, etc, are held in stores at workshops controlled by the foreman and to avoid unnecessary accounting these costs are spread over all vehicles.

Tyres are supplied and fitted by factors and apart from a few complete spare wheels no tyres are held in stock. "On the road" service for punctures, etc, is also covered by these factors. Batteries are dealt with on a similar basis. Brake shoes are on exchange from strategically sited firms giving immediate service. Electrical components are on an exchange basis from national firms and stock depletion arrangements are used. In general, all spare parts used are either as supplied by the vehicle manufacturer or recommended by him.

Vehicles, particularly those in a known livery, have consumer appeal as well as an advertising value and it is most important to keep them clean to maintain a good image.

Arch-type washing plants are installed at the main depots. A system of bodywork renovation and painting is carried out as required, not on a time basis since the condition of vehicles varies widely with different uses.

The gas industry, being concerned with the production and distribution of gas and its wide sales and service to the public and industrial users, makes use of many special vehicles, constructed and equipped to perform functions not encountered in other spheres.

In the case of the South Eastern Gas Board, the design of such vehicles and their equipment has been achieved by co-operation between the various departments and the transport manager and his immediate staff at the central office. Two technical assistants operate from here and assist with the designing and equipping of vehicles, investigate special or repetitive troubles and generally assist in the smooth running of all technical functions of the department.

Servicing and repairs present problems over and above those usually met in the maintenance of some transport fleets.

Radio Many of the cars and vans carry two-way radio, so that particular attention has to be paid to batteries and charging systems—several hundred alternators have been purchased and fitted in place of dynamos, but fortunately many of the newer vehicles have these fitted as standard equipment.

Mobile pumping and generating equipment is serviced in our own workshops, together with hydraulic or electric lifting gear fitted to some vehicles. Cookers and other appliances are delivered in a pre-assembled condition, calling for special cradles and attachments and a large number of the delivery vehicles are purpose-built low-load articulated outfits quite different in construction to the usual types encountered.

Mobile showrooms, both large and small, are of our own design and need particular attention because of the heavy lighting load and the need for extra smartness. Works plant, while for the most part similar to that used in other branches of civil engineering, is subject to very rapid deterioration due to corrosive conditions, calling for extra careful inspection when being serviced.

Several hundred trailers are in constant use, ranging from small tool carriers to caravans for mainlaying personnel, and a wide variety of mobile air compressors, with their high rate of wear and tear, have to be kept in good working order.

Most of the outside garages are only equipped to deal with straightforward transport vehicles, so the maintenance of these "specials" falls upon our own workshop staff, backed up by service from the makers when needed.

One other form of servicing is provided by an independent section oi the transport workshop at Old Kent Road, to which all new vehicles—numbering from 250 to 300 each year, are delivered from the dealers. Each one is inspected and checked and bins, racks or other equipment fitted, faults are notified to the supplier and any necessary adjustments made before issue to the driver. Old vehicles for disposal are. also received there, any usable equipment is removed and the bodywork of goods vehicles sprayed over to cover the distinctive livery before sale.