An Improved Engine Mounting by Austin

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

•

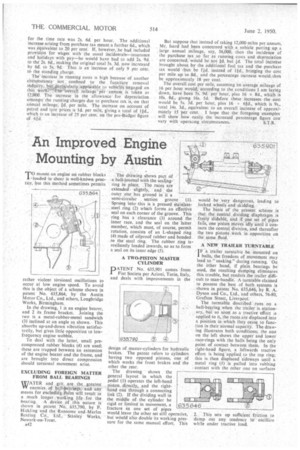

-ro mount an engine on rubber blocks The drawing shows part of -loaded in shear is well-knOwn praca ball-journal with the sealing-' tice, but this method sometimes permits ring in place. The racesare extended slightly, and the

rather violent torsional oscillations to occur at low engine speed. To avoid this is the object of a scheme shown in patent No. 635,864, by the Austin Motor Co., Ltd. and others, Longbridge Works, Birmingham.

In the drawing, 1 is an engine bearer, and 2 its frame bracket. Joining the two is a metal-rubber-metal sandwich (3) inclined at an angle as shown. This absorbs up-and-down vibration satisfactorily, but gives little opposition 'tolowfrequency, engine wobble.

To deal with the latter, small precompressed rubber blocks (4) are used; these are trapped between an extension of the engine bearer and the frame, and are brought into direct compression should torsional movement arise.

EXCLUDING FOREIGN MATTER FROM BALL BEARINGS WATER and grit are the greatest W enemies. of ball4te4ririgs,• and any means for excluding iliem will resillt in a much logger workin4 life for the

bearing. A ,device of this nature is shown in patent. No... 635,790, by F. Hickling and the Ransome and-Marks Bearing Co., 'Ltd.,' StarileY' Works. Newark-on-Trent.

A42 035,864 outer one has ground in it a .

semi-circular section groove (1). semi-circular section groove (1).

• Sprung into this is a pressed staiiilesssteel ring (2) which forms an effective seal on each corner of the groove. This ring has a clearance (3) around the inner race, and the seal on the latter, member, which must, of course, permit rotation, consists of an L-shaped ring (4) made of oilproof rubber and bonded to the steel ring. The rubber ring is resiliently loaded inwards, so as to form

a seal on its inner edge (5).

A TWO-PISTON MASTER CYLINDER PATENT No. 635,901 comes from Fiat Societa per Azioni, Turin, Italy, and deals with improvements in the

design of master-cylinders for hydraulic brakes. The patent refers to cylinders having two opposed pistons, one of which works the front brakes arid the other the rear.

The drawing shows the general layout in which the pedal (0 operates the left-hand piston directly, and the righthand one through a connecting link (2). If the dividing wall in the middle ofthe cylinder be rigid or limited in movement, a fracture in one set of pipes would leave the other set still operative, but would also double-its working pressure for the same manual effort. This

would be 'very dangerous, leading to locked wheels and-skidding.

The basiS of the present scheme is that the central dividing diaphragm is freely slidable, and if one set of pipes fails, one 'piston moves idly until it contacts the central division, and thereafter the two pistons work in opposition on the same fluid.

A NEW TRAILER TURNTABLE IF a trailer turntable be mounted on

balls, the freedom of movement may lead to" snaking" during running. On the 'other hand, if plain bearings be used, the resulting damping eliminates this trouble, but renders the trailer difficult to man-handle: A turntable claimed to possess the best of both systems is shown in patent No. 635,646, by R. A. Dyson and Co., Ltd., and others, 76-80, Grafton Street, Liverpool.

The turntable described runs on a ball-bearing .when the trailer is stationary, bur so soon as a tractive effort is applied to it, the races are displaced into a position in which they cease to function in their normal capacitY. The drawing illustrates both conditions; the one on the left shows the upper and lower race-rings with the balls being the only point of contact between them. In the right-hand figure, a leftwards tractive effort is being applied to the top ring; this is then displaced sideways until a metal ring (1) is pulled into rubbing contact with the other one on surfaces