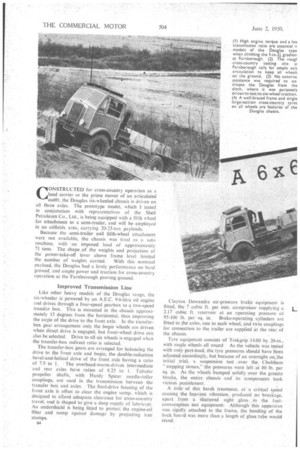

C ONSTRUCTED for cross-country operation as a load carrier or the

Page 38

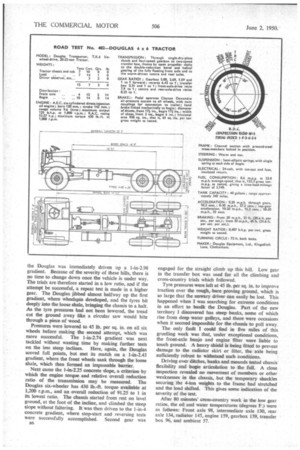

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

prime mover of an articulated outfit, the Douglas six-wheeled chassis is driven on all three axles. The prototype model, which I tested in conjunction with representatives of the Shell Petroleum Co., Ltd., is being equipped with a fifth wheel for attachment to a semi-trailer, and will be employed in an oilfields area, carrying 20-25-ton payloads.

Because the semi-trailer and fifth-wheel attachment were not available, the chassis was tried as a solo machine, with an imposed load of approximately 71 tons. The shape of the weights and projection of the power-take-off lever above frame level limited

the number of weights carried. With this nominal payload, the Douglas had a lively performance on hard ground; and ample power and traction for cross-country operation at the Farnborough proving ground.

Improved Transmission Line

Like other heavy models of the Douglas range, the six-wheeler is powered by an A.E.C. 9.6-litre oil engine and drives through a four-speed gearbox to a two-speed transfer box. This is mounted in the chassis approximately 15 degrees from the horizontal, thus improving the angle of the drive to the front axle. In the transferbox gear arrangement only the bogie wheels are driven when direct drive is engaged, but front-wheel drive can also be selected. Drive to all six wheels is engaged when the transfer-box indirect ratio is selected. "

The transfer-box gears are arranged for balancing the drive to the front axle and bogie, the double-reduction bevel-and-helical drive of the front axle having a ratio of 7.9 to 1. The overhead-worm-driven intermediate and rear axles have ratios of 8.25 to 1. Tubular propeller shafts, with Hardy Spicer needle-roller couplings, are used in the transmission between the transfer box and axles. The final-drive housing of the front axle is offset to clear the engine sump, which is designed to afford adequate clearance for cross-country travel, and is shaped to give a deep supply of lubricant. An undershield is being fitted to protect the engine-oil filter and sump against damage by projecting tree stumps.

azt Clayton Dewandre air-pressure brake equipment is fitted, the 7 cubic ft. per min. compressor supplying a 2.17 cubic ft. reservoir at an operating pressure of 95-100 lb. per sq. in. Brake-operating cylinders are fitted to the axles, one to each wheel, and twin couplings for connection to the trailer are supplied at the rear of the chassis

Tyre equipment consists of Trakgrip 14.00 by 20-in., with single wheels all round As the vehicle was tested with only part-load, the tyre pressures should have been adjusted accordingly, but because of an oversight onithe initial ,trial, a suspension test . over the, Chobham "stepping stotes," the pressures were left at 80 lb. per sq. in. As the wheels bumped solidly over the granite blocks, the entire chassis and its components took vicious punishment.

A mile of this harsh treatment, at a critical spied causing the heaviest vibration, produced no breakage, apart from a shattered sight glass , in the fuelconsumption test equipment. Although this apparatus was rigidly attached to the frame, the bending of the back board was more than a length of glass tube would stand. the Douglas was immediately driven up a 1-in-2.98 gradient. Because of the severity of these hills, there is no time to change down once the vehicle is under way. The trials are therefore started in a low ratio, and if the attempt be successful, a repeat test is made in a higher gear. The Douglas jibbed almost halfway up the first gradient, where wheelspin developed, and the tyres bit deeply into the loose shale, bringing the chassis to a halt. As the tyre pressures had not been lowered, the tread cut the ground away hie a circular saw would bite through a piece of wood.

Pressures were lowered to 45 lb. per sq. in. on all six wheels before making the second attempt, which was more successful. The 1-M-2.74 gradient was next tackled without wasting time by making further tests on the less steep inclines. Here, again, the Douglas scored full points, but met its match on a 1-in-2.43 gradient, where the front wheels sank through the loose shale, which then formed an impassable barrier.

Next came the 1-in-2.25 concrete slope, a criterion by which the engine torque and relative overall reduction ratio of the transmission may be measured. The Douglas six-wheeler has 430 lb.-ft. torque available at 1,200 r.p.m., and an overall reduction of 91.25 to 1 in its lowest ratio. The chassis started from rest on level ground, at the foot of the incline, and climbed the steep slope without faltering. It was then driven to the 1-in-4 concrete gradient, where stop-start and reversing tests were successfully accomplished. Second gear was engaged for the straight climb up this hill. Low gear in the transfer box was used for all the climbing and cross-country trials which followed.

Tyre pressures were left at 45 lb. per sq. in. to improve traction over the rough, bare proving ground, which is so large that the unwary driver can easily be lost. This happened when I was searching for extreme conditions in an effort to baulk the Douglas. Part of the new territory I discovered has steep banks, some of which rise from deep water gulleys, and there were occasions when it seemed impossible for the chassis to pull away.

The only fault I could find in five miles of this gruelling work was that, under exceptional conditions, the front-axle banjo and engine filter were liable to touch ground. A heavy shield is being fitted to prevent damage to the radiator skirt or filter, the axle being sufficiently robust to withstand such conditions.

Driving over ditches, banks and mounds tested chassis flexibility and bogie articulation to the full. A close inspection revealed no movement of members or other weaknesses in the chassis, but the temporary shackles securing the 4-ton weights to the frame had stretched and the load shifted. This gives some indication of the severity of the test.

After 80 minutes' cross-country work in the low gear ratios, the oil and water temperatures (degrees F.) were as follows: Front axle 98, intermediate axle 130, rear axle 134, radiator 145, engine 159, gearbox 139, transfer box 96, and ambient 57. Tyre pressures were readjusted to 80 lb. per sq. in before returning to the road. Here the fuel consumption was measured over a 10-mile course on the A30 road, the test finishing on the outskirts of Staines. As only a partial load was carried, the performance was exceptional and, apart from two involuntary stops, little demand was made on the indirect ratios. A result of 8.6 m.p.g. was obtained at an average speed of 23.8 m.p.h., the vehicle being driven at maximum governed speed wherever conditions permitted.

In the short performance trials, I was fortunate in locating a newly surfaced level stretch of road, where all six tyres took a good grip during the braking trials, which produced a stopping distance of 45 ft. from 30 m.p.h. There was slight wheel locking, but the addition of full load would improve the adhesion between the tyres and the road.

Acceleration tests showed that to reach 30 m.p.h. from rest would occupy 37.2 secs. when moving away in second gear. Top-gear performance from 10-30 m.p.h. was equally as brisk, and without noisy resentment from the transmission.