THE INFLUENCE OF •TREAD ION ON TYRE PERFORMANCE

Page 26

Page 27

Page 28

Page 29

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

A Close Investigation .of the Reasons For and Against the Adoption of Particular Tread Patterns, and Their Influence on Tyre Life

By E. C. Woods, B.Sc.

(Henley's Tyre and Rubber Co., Ltd.)

DURING recent years, the study of the characteristics of pneumatic-tyretreads, at various professional institutes, universities and works laboratories, has led to the publication of a considerable amount of information on the technical aspects of tread design.

The properties in an ideal tyre-tread pattern should provide for: (1) Long life; (2) non-skid under all conditions; (3) quiet running; (4) capabilities of transmitting evenly distributed stsesses to the carcase; (5) assisting easy and safe steering; (6) freedom from incidental faults,ssuch as cracking in grooves and throwing up stones, etc.; (7) even wear; (8) appearance.

With the exception of the last-named, all are of a technical nature. In what follows, each feature is discussed and its inter-relation in respect to other features is cons sidered because, what may be ideal for one may be detrimental in another. Hence, in finalizing a tread design, it is necessary to strike some sort of an average to secure the best all-round performance of the tyre.

(1) Long Life . The life of pneumatic tyres, during recent years, has greatly improved in spite of the fact that average speeds of vehicles have considerably increased. As will be pointed out later, this is probably due to the aim, in designing the tyre, of satisfying the customers' ultisnate demands. It is, however, considered by some writers, that users are apt to exaggerate the importance of mileage and to overlook safety.

Points that must not be forgotten in comparing mileages of different tyres used under varying conditions, have been defined by observations made by various investigators,1 and here are some of them:—(a) Increasing the average speed of a vehicle from 30 to 50 m.p.h. doubles tyre wear; (b) in dry weather wear may be 10 times as great as in wet weather; (c) in the summer, wear may be three times greater than in the winter; (d) it has beers found that differences in driving technique can account for variations from 8,000 miles to 33,500 miles in the life of similar covers; (e) the wear which takes place when acceleration or retardation forces are applied may be five times as great as when coasting the same distance.

Effect on Tyre Life of Contact Area Friction There is no question that tyre wear must be linked up with the coefficient of friction between the tyre and the road, and that efforts made to improve the friction will result in decreased tyre life. A study of frictional phenomena between tyres and roads, has come in for considerable' attention. There is no question that, under normal running, all parts of the tyre tread, while in contact with the road, do undergo varying forces in the plane of the road which result in creepage phenomena, and hence wear characteristics are affected.

Dr. C. Schmid2 has examined the effects of the rolling of a tyre on a road and has shown that, as the tread enters the contact ellipse, it compresses and recovers again on leaving it. Actually, with a tread pattern, as the tread leaves the contact surface, it springs back into position and thus causes wear on the following edges of the pattern (Fig. 1).

This compression and recovery of the tyre tread results in creepage, and Schuster and Weichsler3 have determined, from theoretical considerations, that the range of creepage within which conditions of adhesion between the tyre and the road obtain, is of the older of 15 per cent, lag or lead. If higher peripheral forces be transmitted then slide or slip occurs, The creepage which takes place accounts for relative movements in various parts of the tyre tread within the contact ellipse, hence there is a certain amount of wear while in actual contact with the road. ,

E. A. Roberts4 has carried out experiments by depositing a coating of silver on a glass plate; then sprinkling the surface with an abrasive and afterwards driving over it with a tyre. In this way, the movement of the tyre elements within the contact area is clearly shown by linos caused by the movement of the abrasive particles on the silver coating.

It was found that the actual movement consisted of small curved paths (Fig, 2), and that these paths ware of the order of five times as -large for an accelerating wheel as for coasting conditions.

Following the theory that wear takes place by the action of the tread elements leaving contact, with the road, it is clear that dividing the pattern into small blocks, as in the case of slotted treads, will, because of the large number of flexible elements, lead to rapid wear.

(2) Non-skid Under All Conditions

In the first place, a tread design is

required to improve the non-skid properties. Many investigators have compared plain-treaded tyres svith patterned tyres and are unanimous in stating that, when the roads are wet, the friction between wheel and road is increased to something like 50 per cent, by a pattern. When roads are dry, measurements show improvement to vary from a very • small value to 40 per cent. with the wheels rolling, and 28 per cent, when the wheels are locked.4

The ordinary mechanism of a sliding body on a stationary one is well known, and the coefficient of friction is less in the case of a body moving than for a body on the point of moving. The theories concerning tyres are based on the assumption that the broken pattern wipes over the surface of a slippery road and this enables the following tread elements to remain substantially in static contact with the road and thus allow of tractive efforts being transmitted.

Against the advantages of a patterned tread must be set the disadvantages, that slipping on a road gives rise to a shrieking noise and power, consumption of the tyre is also greater, For general road purposes, the ratio of solid surface to a void surface in a tread pattern is ustially of the

order of 65 per cent. '

A tyre company in the U.S.A. has recently conducted a large-scale experiment on the design of tyre treads and has measured the frictional properties for a number of standard tread designs.

From the results obtained the concern drew the conclusion that the function of a tread, in preventing skidding, is to wipe the road free of lubricant, and an effective design must allow the quickest possible flow of water. from under the tyre. The company found that, as the speed of rolling increases, the coefficient of friction decreases.

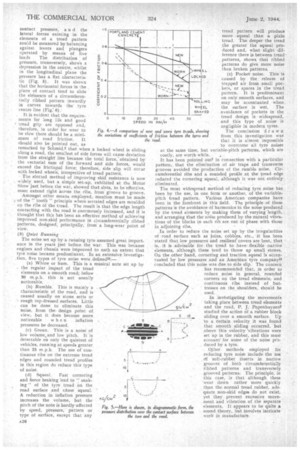

Actualresults, reported by J. M. Lesse115,5 showed that both the rolling and static friction increased for a plain

circumferential rib design as the ribs were, reduced in width and their number increased. This was much greater for grooves 0.080-in. oxide than for grooves 0.20-in. wide. At the same time, the rolling coefficient increased approxirnately twice as much as the sliding coefficient.'

Using transverse ribs, the rolling friction was found to be but little higher than the sliding friction, and both coefficients passed through a maximum as the width of the ribs was 'reduced from 1 in. to 0.2 in. Actually, in the case of ribs ir in. wide the coefficients of friction were about 60 per cent, greater than for a smooth tyre with grooves 0,80-in, wide and, in this case, widening the grooves between the ribs to 0.2 in resulted in a further 10 per cent improvement.

When using angular ribs, both rolling and sliding friction were found to be high. In the case of bars at 45 degrees to the centre line, an increase in width from 0.25 in. to 0.5 in.resulted in a drop from a coefficient of friction 100 per cent. better ttan a smooth tyre, to 75 per cent, better than asmooth tyre after passing through maximum. It was found that good values of friction were obtainable for angles greater than 30 degrees to the centre line of the pattern. In order to obtain the hest wiping action it was concluded that a minimum width of 0.35 in. was necessary for ribs at

Very good

45 degrees and in the carter of 0.5 in. for transverse ribs.

The optimum wiping action occurs when the ratio of bar-width to groove-width is 0.25 to 0.35. A summary of the results is given in Fig. 3. Conclusions were, that the best all-weather skid-resisting pattern would consist of bars 0.33-in, wide with Fin, grooves at an angle of 30 degrees to the centre line of the tread, and the adopted pattern involved ribs to these dimensions inclined on both sides of the centre line.

The investigations of Dr. Schmid2 have already been mentioned, artd he deterinined that a drawn or braked wheel lags„ whilst a driven wheel leads when tractiVe forces exist between the wheel and the road. If higher peripheral forces be transmitted, so that slide or slip occurs, it is evident that the limit of static friction between the tyre and the track has been exceeded.

Dr. Schmid Pointed out that, with a tread of crosscountry design, the pattern forms a rack and pinion and transmitted tractive forces are, therefore, limited by the shearing strength of the track material. In this case there is no actual frictional force between the road and the tread. Schmid also mentions measurements made by Weil and Knipping, who found that high frictional forces are obtainable only with greater than 18 per cent, lag for conditions of retardation.

Improving Tyre Grip on Unstable Road Surfaces

In order to improve grip on wet and slippery roads, it was stated tha: finely cut patterns are the only solution. Various theories have been put forward for this, and they are summarized by Schmid as follow:—

(a) Due to Sommer. Intermediate material is squeezed away from the road surface by the elements of the tread pattern. This fluid is taken up by the transverse grooves, whence it is carried away from the contact ellipse, either by centrifugal forces or by pumping action of the tread. The sharp corners of the tread pattern are then able to exert a grip on the road surface.

(b) Alternatively, it has been stated that, assuming the creepage phenomena exerts itself in relative movement of the various tyre parts within the contact surface, this gives rise to frictional forces when. the tyre surface is divided up: then the stresses between the individual parts of the pattern are diminished and greater elasticity is obtained, Hence, each part of the tread can accommodate itself to its relative road-contact surface.

The theory that the transverse grooves form essential parts of a non-skid pattern for providing outlets for the road water and mud, has also been referred to by A. Healey.°

It is considered that road-holding properties are enhanCed by flexible extreme ribs of the tread pattern. These ribs are not in contact with the road surface in straightforward driving but, when braking, accelerating or cornering occurs, the additional deflection of the tyre brings the ribs into contact, and they act as squeegees and wipe away any film of water or mud.7

Holt and Cook° have also carried out determinations of the tread movement during the running of a tyre on the road, and they found that the elements of rubber undergo both lateral and rlongitudinal movements resulting in creepage.

P. J. Papenhuyzen,9 again, investigated the phenomena and found that, on wet surfaces, frictional forces are sometimes greater when lateral mtwements take place. At low speeds, however, the effect of the lateral displacements is to reduce the coefficient of friction and, as the displacements of worn tyres are less than with new tyres, the coefficient, in a longitudinal dieection, is greater in the case of an old tyre than in a new tyre. At high speeds, however, the opposite effect takes place and, therefore, the new tyre shows' better characteristics. The curves stated by Papenhnyzen to have been obtained by Stinson and Robertsi° are given in Fig. 4. Herbert Martini' developed an .apparatus in which the

contact pressure, a n d the lateral forces existing in the elements of a tread pattern could be measured by balancing against levers and plungers operated by means of live loads The distribution of pressure, transversely, shows a depression in the centre, whilst in the longitudinal plane the pressure has a flat characteristic (Fig. 5). It was shown that the horizontal forces in the plane of contact tend to slide the elments of a circumferendaily ribbed pattern inwardly in curves towards the tyre centre line (Fig." 6),

, It is evident that the requirements for long life and good

e tread grip are opposed and, therefore, in order for wear to be slow there should be a minimum of road friction. It should also be pointed out, as remarked by Schmid,2 that when a locked wheel is sliding along a road, the smallest of side forces will cause deviation from the straight line because the total force: obtained by the vectorial sum of the forward and side forces, would exceed the frictional force; therefore, side slip will occur with locked wheels, irrespective of tread pattern.

• The slotted method of improving skid resistance is now widely used, but a simple set-up, exhibited at the Motor Show just before the war, showed that slots, to be effective, must extend right across the ribs, from groove to groove. -Amongst other means employed, mention must be made

• .( of the " tooth " principle where serrated edges are moulded on the ribs of the tread. The result is that the edge length contacting with the road is enormously increased, and it is thought that this ha:s been an effective method of achieving improved non-skid performance in circumferentially ribbed patterns, designed, principally, from a long-wear point of view.

(3) Quiet Running

The noise set up by a running tyre assumed great importance in the years just befoie the war: This was because engines and chassis were improved to such an extent that tyre noise became predoniinant. In an extensive investigation, five types of tyre noise were definet112:—

(a) Whine or hum. This is a musical note set up by the regular impact of the tread elements on a smooth road; below 30 m.p.h. this is not usually noticeable. • (b) Rumble. This is mainly a characteristic of the road, and is caused usually on stone setts or rough top-dressed surfaces. Little can be done to eliminate this noise. from thedesign point of view, but it does become more noticeable when inflation pressures be decreased.

(c) Groan. This is a noise of low volume‘and low pitch. It is

detectable on only the quietest of vehicles, running at speeds greater • than 25 m.p.h. The use of continuous ribs on the extreme tread edges and rounded tread profiles hi this region do reduce this type of noise.

(d) Squeal. Fast cornering and fierce braking lead to " snak ing " of the tyre tread on the

road surface and cause squeal. A reduction in inflation pressure

increases the volume, but the pitch of the note is hardly affected by speed, pressure, pattern or type of surface, except that any tread pattern will produce more .-squeal than a plain tread. The deeper the tread the greater the squeal produced and, what slight difference there is between tread patterns, shows that ribbed patterns do give more noise than broken patterns.

(e) Pocket noise. This is caused by the release of trapped air from small pockets, or spaces in the tread • pattern. It is predOminant on only smooth surfaces, and may be accentuated when. the surface is wet. The avoidance of pockets in the tread design is widespread, and this type of noise is negligible in modern tyres.

The conclusion drawn from this investigation was that it is almost impossible to overcome all tyre noises at the same time, but variable-pitch patterns, which are costly, are worth while.

It has been pointed out7 in connection with a particular pattern, that the elimination of air traps and transverse grooves avoided the production of the rumble noise. Circumferential ribs and a rounded profile at the tread edge reduced the cornering squeal, although it was not entirely eliminated.

The most widespread method of reducing tyre noise has been by the use, in one form or another, of the variablepitch tread pattern. Various American companies have been in the forefront in this field. The principle of these patterns is the avoidance Of harmonics in the noise produced by the -tread elements by making them of varying length, and arranging that the noise produced by the natural vibra: tions of the blocks in each rib are out of phase with those

in adjoining ribs. _

In order to reduce the noise set up by the irregularities of road surface such as joins, cobbles, etc., it has been stated that low pressures and resilientecovers are best, that is, it is advisable for the tread to haveflexible -narrow elements, although these tend to throw up small stones. On the other hand, cornering and traction squeal is accentuated by low pressures and an American tyre company'3 concluded that this noise was due to side slip. The concern

has recommended that, in order to reduce noise in general, rounded corners on the tread elements, and continuous ribs instead of buttresses on the shoulders, should be used.

In investigating the movements

taking place between tread elements and the road, P. J. Papenhuyzens studied the action of a rubber block

5 io sliding over a smooth surface. Up to a certain velocity it was found that smooth sliding occurred, but above this velocity 'vibrations were set up in the rubber, and this must account' for some of the noise produced by a tyre. • 1.-*

A • 0.ther methods employed foi

reducing tyre noise include the use crf soft-rubber inserts in narrow grooves of both circumferentially ribbed patterns and transversely grooved patterns. The principle, in this case, is that although these 'wear down rather more quickly than the normal tread rubber, ade.

quate non-skid edges do not 'exist, yet they prevent excessive movement and vibration of the separate elements. It appears to be quite a sound theory, but involves intricate work in manufacture. (4) Even Distribution of Stresses to Carcase If is evident that an ideal tread pattern is useless if it leads to serious trouble in the carcase, and the design of the tread must, therefore, take this point into account. The most recently designed covers of various manufacturers have all changed to the use of a bi-radius tread, so that shoulder buttresses are rounded off and, as a result, any severe road shock which causes deflection of the tyre beyond the tread edge, does not cause rapid change of curvature in the carcase material.

For normal road operation a pattern, such as has been generally adopted for cross-country work, with prominent 'transverse strakes, would lead to early trouble ia the shoulder region.

(5) Easy and Safe Steering

The pattern of a tyre tread does affect the riding characteristics of a vehicle, although in only a small degree; by this is meant that the ability to absorb road irregularities is influenced by the pattern. This property is affected mainly by design details other than the tread, but it has been found that the use of a light, open, tread-pattern design is advantageous, afthough it may have a short life.

From the safety point of view, cornering ability is important, and here the use of small elements, particularly with deep pattern thickness, are not advisable.

(6) Incidental Faults, Such as Cracking in Grooves, etc. Flexible treads Which are advantageous from the road. friction point of view, tend to throw up small stones and suffer irregular chipping on the road. Patterns incorporating narrow grooves are objectionable on account of -the small stones that are picked up and retained.

Before the war, when highgrade natural-rubber compounds were used for treads, tread cracking was not very serious, but, unquestionably, it was more predominant in circumferentially grooved patterns. The use of saw-cuts in the mould ribs, to assist tread flow, has been found to commence tread cracks and in recent years there has been a noticeable .change to drilled vents, although these are less effective in moulding.

Whilst circumferential-rib patterns lead to cracking, they are free from faults of tread tearing in mould extraction. Care must be taken in designing tread patterns to avoid the use of elements with complicated shapes which tend to be held in the mould and cause tearing when tyres are extracted. This aspect is of more importance with lowgrade rubber compounds and synthetic rubbers than with high-grade compounds. A. W. Grote14 has listed the nonskid tread design as being first in order of importance of the factors affecting flex cracking.

Various unusual designs, to avoid incidental faults, have been used 'from time to time, but do not appear to have achieved popularity. These include the employment of grooves just below the shoulders to provide cooling of the shoulder regions. On the other hand, "tie-in blocks," of approximately half the depth of the pattern at vulnerable points, are included in nearly all patterns to avoid " patchy " wear and groove cracking.

(7) Even Wear Uneven wear is not, in itself, a disadvantage when it is due. to the pattern alone but, in practice, it is synonymous with rapid tread wear and can often be avoided by modifications to the pattern.

To some extent, uneven wear is associated with variation in contact pressure and, as pointed out by Healey,6 the presence of grooves in the pattern does not affect the general elliptical shape of the contact surface, but it does result in the remaining rubber bearing greater loads and an increase in the average, pressure. Hence, from this point of view, it is advisable for grooves to be as narrow as possible.

Tests on small model solid tyres have been carried 'out by Dr. H. P. Zoeppritz and L. Huber,16 to investigate the cause of wear in saw-tooth and wave formation. It was C-TsC) .al 2 3 4 $ KG/CM2 found that tyres with smooth surfaces and those with plain ribbed designs showed practically no saw-tooth or wave shape wear. On the other hand, tyres with block patterns commenced to wear as a saw-tooth which later developed into waves. These phenomena were explained in this way:— There is little deflection of the tread elements in the line of travel until the blocks enter the stressed portion, that is the zone of contact which is already deflected when there is a tractive effort present. As the tread elements pass through the zone of contact, the stress varies until the friction force is less than the initial stress, when individual blocks slip, or spring back, into position. Therefore, the last part of the tread block,or the following edge, suffers abrasion in leaving the surface (see Fig. I). Evidence of similar effects can be observed after tyres have been Used. on wheels which do not ran true.

Tests carried out on pneumatic tyres on the road confirm both the laboratory results and the explanation. The following edges of the tread blocks are, first; worn away much quicker than are the leading edges and, after nearly all the pattern has been worn away, the wear cleVelops into wave formation.

Some tests were carried out with plain rib-patterned treads, but buttress blocks and saw-tooth wear occurred on the buttresses. Parallel tests were also carried out by the Adler-Werke, of Frankfurt-on-Maine, which confirmed the foregoing results. It was concluded that uneven wear was chiefly due to tread pattern, although in practice, mechanical considerations also have to be taken into account.

Experiments carried out by Professor Hans Kluge and Egon Hass16 showed that, in tyres running at high speeds, standing waves formed in the tread surface immediately behind the contact area. No mention is made as to whether it was observed that these occurrences caused unusual tread wear, but it was noted that a rapid increase to slip, or creepage, coincided with the formation of the waves at high speeds. The chief property affected by the formation of the standing waves appears to be the power consumption of the tyres, with which we are not at the moment concerned.

As previously mentioned, " tie-in blocks " are a recognized means for combating uneven wear when incorporated in the pattern at the correct places.

(8) Appearance It is interesting to note that, whilst a consumer will almost certainly 'make purchases on appearance, he will, ultimately, assess his judgment on the mileage which has been obtained from the tyres. Very often, it is a case that, in the early days of the use of a new set of tyres, an operator or driver will complain, for example, of the poor non-skid properties of a particular make. When, however, the tyres are ultimately worn out he has forgotten the shortcomings he noticed in the early days and before replacing the tyres is more concerned with the number of miles per unit cost.

Although it is necessary for a tyre to have a pleasing appearance, and to look as though it had all the properties of long life, good road-holding, quiet running and so on, it is a quality which, obviously, cannot be put down on .paper. It is interesting to note, however, that users appeal to be impressed by buttress and side wall designs, although it is doubtful whether these contribute anything to theproperties of the tyre.

The value of appearance is probably more greatly appreciated in the United States than in this country, as is shown by the popularity of white side wall tyres before the war. Elaborate side wall designs have also been used to attract the customers' attention, and there is no doubt that the appearance is probably improved by ribbed low walls, etc. In summarizing the foregoing, it is dear that the research carried out by each investigator on different subjects has led to confirmatory results, and the following is deduced from observations and conclusions of the various investiga

(Th

CENTR LINE

tons which have been refereed to, in which the basic prin. ciples in tread design are set out for each property:—

(a) To reduce wear to a minimum, it is advisable to avoid block edges which contact with the road within the contact ellipse, and spring back on leaving it. Circumferential ribs appear the most advantageous, (b) For the best forward-skid resistance, transverse ribS are recommended, but it has been stated that, for all-round performance, ribs at 30 degrees to the centre line are best. The use of finely cut patterns (slotted) greatly improve all designs, and serrated edges have proved advantageous on patterns with otherwise normal non-skid properties.

(c) Regular tread patterns must be avoided where it is required that the production of noise be at a minimum. Continuous ribs on the shoulders are a help, and the avoidance of " pockets " in the pattern is recognized as essential. It has been found that round corners on tread elements are also helpful from the point of view of reducing noise.

(d) Narrow grooves, rounded shoulders and the avoidance of isolated tread ,elements, are desirable to prevent localized stresses on the carcase.

(e) To assist easy steering a light, open-tread pattern is required.

(f) Circumferential grooves, small flexible elements, narrow grooves, saw-cut mould vents, and complicated moulding shapes all lead to _faults classed as "incidental," (g) To avoid uneven wear it is desirable to use ribbed designs with narrow grooves. (h) The appearance of a tyre is important, and operators are apt to be attracted by patterns appearing to possess certain properties which any amount of technical data might prove they have not. The eesthetics of side wall design appear to have passed

• from tendencies of prominent looking rugged buttresses through a preference for sleek, clean-looking surfaces— as found on many covers of immediate pre-war design —to highly decorated side walls apparent in designs of

• more recent innovation.

On account of the differing requirements to obtain the various characteristics, it is clear that all the conclusions cannot be applied in one tread design. To some extent, also, new designs must be dependent upon the trend of opinion. Just before the war, for example, the elimination of noise came to the forefront, but it would not be advisable for manufacturers to follow this trend to the detriment of other properties, unless it be found that users be of one mind in objecting to the noise made by current designs.

REFERENCES 1. '' The Effect of Speed ii Tyre Wear." The technical editor— "The Motor," June 24, 1942. 2. C.. Schmid. "Frietiona Forces Between Tyre And Road." A.T.Z., vol. 41, 1938, pp. 392-398. 3. Schnster-Weichsler. A.T.Z. (1935). p. 499.

4. E. A. Roberts. , ' Designing the Tyre for the Car." EI.A.E. Journal, vol. 44, June, 1939, p. 243,

5. J. M. Lessens. "A Rational Approach to Tyre Tread Design?' Mech. Eng., February, 1939, pp. 125-130.

6. A. Healey. " The Tyre as Part cl the Suspension System." I.R.J., vol. 68 (1924), P. 1200.

7. "The Motor," May 16, 1939, p. 577.

8. Holt and Cook. "Measurement of Tread .Movement of Pneumatic Tyres and a Discussion of the Probable Relation to Tyre Wear," "Rubber Age,' vol. 19, November, 1928, pp. 324-328. 9. P. J. Papenhuyzen. "Friction Tests in Connection with Motor Tyre Slip." "tie Ingenieur," November 11, 1938, pp. 75-87:

10. Stinson and Roberts. "Coefficient of Friction Between Tyres and Roadway." 11. H. Martin, " Pressure...Distribution in the Contact Surface Between Tyre and Road." Kraftfahrtechnische Forschungsarbeiten, vol. 2, pp. 6-14.

12. C. D. Law "Pyre Requirements for Modern Transport.'' Jnl, A.E. Proceedings, vol. 3.3, November, 1938, pp. 211-274.

13. W F. Busse. "Physios of Rubber as Related to the Automobile." Jot. of Applied Physics, July, 1938, Vol. 9, pp. 438-451. 14. A. W. lirote. "Factors Affecting Flex Cracking in Tyre Treads." "The Rubber Age," N.Y., vol. 38, March, 1936, p. 15. H. T. Zoeppritz and L. Huber. " Wave-shaped Tyre Wear." D. Eraftfahrforsch, No, 15, 1938.

16. Hans Kluge and Egon 1Tass. D. Kraftfahrtforsch., No. 26, 1939.