THE MANUFACTURE AND USE OF SMALL TOOLS.

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

Designs and Methods Suggested by Our Driver and Mechanic Readers.

ASCREWDRIVER fixture for attachment to a bench may be of considerable assistance to those whose work necessitates constant use of such a tool for assembly or repair purposes. " C4.A.L.," of Washington, D.C., to whom this week's prize of 15s. has been awarded, submits a design —which appears to be practical and may interest many of our readers whose daily work lies in the shops.

A steel plate is taken and bent to foriu a" foot" for attachment to the bench, the upper end being curved round to act as a bearing for the spindle of the device. Three bolts fix the " foot " to the bench and two bolts or rivets ensure rigidity for the spindle bearing. The spindle has two collars, one at each end, and there is a recess in each collar to accommodate the handle in one case and the detachable screwdriver blade in the other. The handle, of course, may be permanently fixed, but provision should be made for making the blades removable in order that various sizes of screws may be dealt with.

In operation all that the mechanic has to do is to turn the handle with one hand and press the work up against the rotating blade with the other, the screw being started previously a matter of two or three turns.

AFTER an engine overhaul a mechanic has little means of telling whether his work is of a lasting nature, and the use of a combined pressure and vacuum gauge for compression testing and so forth is well worthy of consideration. " H.E.S.," of Holbeck, finds that a second-hand combined steampressure and vacuum gauge, screwed into an old sparking plug body, is a serviceable instrument.

In the first instance, the body of the plug must have a suitable thread to fit into the sparking plug holes of the engine in question, the inside of the body being tapped out to receive the gauge. It will be quite sufficient for a reading of 100 lb. per square inch to be obtained on the pressure side.

By applying the gauge to each cylinder in turn, the condition of valve seats, piston rings, pistons, and the various joints may be verified.

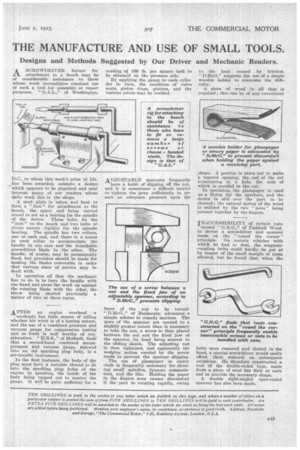

ADJUSTABLE spanners frequently have a habit of slipping off the nut, and it is sometimes a difficult matter to tighten the jaws sufficiently to ensure an adequate pressure upon the faces of the nut to be turned. "D.McG.," of Benbecula, advocates a simple scheme to remedy matters. The jaws of the spanner are opened to a slightly greater extent than is necessary to take the nut, a screw is then placed between the nut and the fixed jaw of the spanner, its head being nearest to the sliding shank. The adjusting nut is then tightened, and apparently the wedging action exerted by the screw tends to prevent the spanner slipping.

The use of glasspaper or emery cloth is frequently necessary for cleaning small spindles, dynamo commutators, and the like. Holding the paper in the fingers soon causes discomfort if the part be rotating rapidly, owing

to the heat caused by friction. "D.MeG." suggests the use of a simple wooden holder to overcome the difficulty.

A piece of wood is all that is required ; this can be of any convenient

shape. A portion is sawn out to make -a tapered opening, the end of the cut terminating in a hole, the axis of which is parallel to the cut.

In operation, the glasspaper is used as a lining for the aperture, and the device is slid over the part to be cleaned ; the natural spring of the wood is utilized by the two " jaws " being pressed together by the fingers.

INACCESSIBILITY of certain nuts caused " G.N.G.," of Paddock Wood, to devise a screwdriver and spanner made on the "round the corner" principle. On certain vehicles with which he had to deal, the magnetocoupling bolts could hardly be got at by reason of the small margin of room allowed, but he found that when the

bolts were removed and slotted in the head, a special screwdriver would easily effect their removal on subsequent occasions. He therefore constructed a tool of the double-ended type, made from a piece of steel bar Sled at each end to provide the necessary shape.

A double right-angled open-ended spanner has also been made.