CHASSIS SELECTION:

Page 16

Page 17

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

-ANCE A VITAL FACTOR. A FEW weeks ago we dealt editorially with the .C1 difficulties experienced by some manufacturers through the insistence by potential buyers on small deviations from standard practice. Our remarks were chiefly confined to those small and worrying details which are often of very little importance, but we concluded by saying that we did not suggest that potential buyers should altogether refrain from asking for special types of vehicle, as it is often through such insistence that new and important designs are evolved.

Following up this line of argument, it will be of interest to consider a specific instance where a buyer has ordered a number of vehicles only upon the condition that they embodied certain important features in their construction following upon conclusions arrived at after many years' expesience with vehicles of an sizes and types. We refer to Selfridge and Co., Ltd., who, on purchasing a dozen chassis of Star manufacture between June and December last year, commenced by buying one standard 25-cwt., and after considering certain points in its design, ordered the remaining 11 on the condition that they were so modified as to embody, so far as possible, the features which were favoured by the Selfridge transport department.

Following Theory by Practice.

The whole matter may be considered as the follow-up of a paper which was read in February, 1924, by Mr. A. E. Cowper, a director of Selfridge and Co., Ltd. In this he drafted a specification in which he centred his consideration on three points:

(1) simplicity of construction to give the driver every facility for carrying out minor running adjustments; (2) the ease with which the various wearing parts can be replaced or attended to when the Car is in the garage ; (3) economy as regards actual 'running cost. In addition to these main points, he asked for a chassis which would carry a maximum load, including the body, of 30 cwt., which should not exceed from 17 cwt. to 20 cwt. bare ; should have an engine of approximately 15 h.p. by R.A.O. rating ; a gearbox giving four speeds and with -right-hand change, and a fully floating rear axle with adjustable roller bearings ; where a transmission brake is employed, it should be controlled by hand, whilst the foot brake should always act on large drums on the rear wheels.

532 Many other smaller details were mentioned, including more convenient oil fillers, but we have not the space at our disposal to deal with these Individu ally. • At this point, it may be as well to consider this matter of meeting the requirements of the user. In designing a chassis, the manufacturer has many points to take into account. Possibly the primary one. is cost and, in conjunction with this, there are, naturally, ease of manufacture and rapid assembly, and sometimes perhaps too little thought is given to the nuestions of accessibility and ease of maintenance once the vehicle .is on the road. Take, for instance, unit construction. From the manufacturing point of view, this is almost an ideal arrangement. The alignment when new can he made • almost perfect and the whole unit forms a neat job which can be dropped into the chassis without any great difficulty, but when it comes to maintenance the user is not always so pleased with this form of construction. If, for instance, trouble is experienced with the clutch, the whole .unit may have to be dismantled, as it is seldom possible to remove a clutch cone, say, for refacing without SO doing. Likewise the alignment, although perhaps perfect when the vehicle is new, may be upset if the main bearings be taken up, a point which does not always receive the consideration which it merits.

Users in a big way have many opportunities of testing out the merits of various forms of construction and, consequently, their opinions should bear .very considerable weight with the manufacturer. In the case of the Star chassis purchased by Selfridge and Co., Ltd., the company were quite satisfied with the quality of the standard Star, but it is doubtful whether they would have ordered more if their requirements had ht been met by the makers in the handsome way in which they were.

In the standard Star 25-cwt. model there is an engine of 20.1 h.p. with its four cylinders cast en block and with detachable heads. The magneto is mounted at the near side well forward, allowing an easy view of the make-and-break, one of the features mentioned by Mr. Cowper. The clutch however, is of the single dry-plate type, and the four-speed gearbox is bolted direct to the crankcase enclosing the flywheel, clutch and withdrawal gear, whilst the rear axle is of the semi-floating type driven by an overhead worm.

The Modified Star.

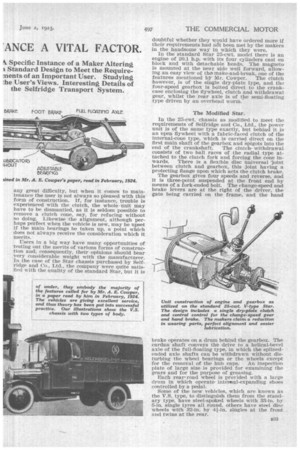

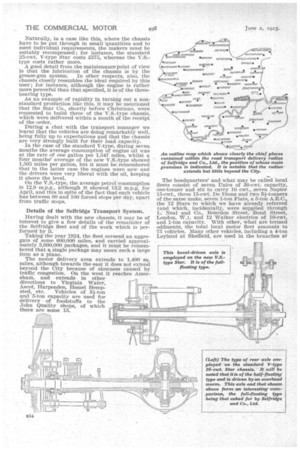

In the 25-cwt. chassis as modified to meet the requirements of Selfridge and Co., Ltd., the power unit is of the same type exactly, but behind it is an open flywheel with a fabric-faced clutch of the internal-cone type, which is carried direct on the first main shaft of the gearbox and spigots into the end of the crankshaft. The clutchwithdrawal consists of two ball races of the radial type attached to the clutch fork and forcing the cone inwards. There is a flexible disc universal 'joint between clutch and gearbox, this Joint having a protecting flange upon which acts the clutch brake.

The gearbox gives four speeds and reverse, and it is three-point suspended at the front end by means of a fork-ended bolt. The change-speed and brake levers are at the right of the driver, the gate being carried on the frame, and the hand brake operates on a drum behind the gearbox. The cardan shaft conveys the drive to a helical-bevel axle of the full-floating type, in which the splinedended axle shafts can be withdrawn without disturbing the wheel bearings or the wheels except for the removal of the hid) caps. An inspection plate of large size is provided for examining the gears and for the purpose of greasing. Each rearroad wheel is provided with a large drum in which operateinteonal-expanding shoes controlled by a pedal. Some of the new vehicles, which are known as the V.S. type, to distinguish them from the standary type, have steel-spoked wheels with 33-in. by 5-in, single tyres all round, others have steel disc wheels with 32-in. by 41-in. singles at the front and twins at the rear. Naturally, in a case like this, where the chassis have to be put through in small -quantities and to meet individual requirements, the makers must be suitably recompensed ; for instance, the standard 25-cwt. V-type Star costs £375, whereas the V.5.type costs rather more.

A good detail from the maintenance point of view is that the lubrication of the chassis is by the grease-gun system. In other respects, also, the chassis closely resembles the ideal required by this user ; for instance, although the engine is rather more powerful than, that specified, it is of the threebearing type.

As an example of rapidity In turning out a nonstandard production like this, it may be mentioned that the Star Co., shortly before Christmas, were requested to build three of the V.S.-type chassis, which were delfvered within a month of the receipt of the order.

During a chat with the transport manager we learnt that the vehicles are doing remarkably -well, being fully up to expectations and that the chassis are very strongly built for their load capacity.

In the case of the standard V-type, during seven months the average consumption of engine oil was at the rate of one gallon per 1,547 miles, whilst a four months' average of the new V.8.-type showed 1,505 miles per gallon, but it must be remembered that in the latter case the engines were new and the drivers were very liberal with the oil, keeping it above the level.

On the V.S.-type, the average petrol consumption is 12.9 m.p.g., although it showed 13.2 m.p.g. for April, and this in spite of the fact that each vehicle has between 90 and 100 forced stops per day, apart from traffic stops.

Details of the Selfridge Transport System.

Having dealt with the new chassis, it may be of interest to give a few details of the remainder of the Selfridge fleet and of the work which is performed' by it.

Taking the year 1924, the fleet covered an aggregate of some 600,000 miles, and carried approximately. 3,000,000 packages, and it must be remembered that a single package may mean such a large item as a piano.

The motor delivery area extends to 1,400 sq. miles, although towards the east it does not extend beyond the City because of slowness caused by traffic congestion. On the west it reaches Amersham, and and extends in other directions to Virginia Water, Ascot, Harpenden, Hemel Hemp sted, etc. Vehicles of 3i-ton and '5-ton capacity are used for delivery of foodstuffs to the John Quality shops, of which there are some 15. The headquarters' and what may be called local fleets consist of seven Unics of 30-cwt. capacity, one-tonner and six to carry 10 cwt., seven Napier 15-cwt., three 15-cwt. De Dions and two 3i-tonners of the same make, seven 1-ton Fiats, a 5-ton A.E.C., the 12 Stars to which we have already referred (and which, incidentally, were supplied through L. Neal and Co., Bourdon Street, Bond Street, London, W.), and 12 Walker electrics of 10-cwt. and 1-ton capacity. With other, what are termed oddments, the total local motor fleet amounts to 75 vehicles. Many other vehicles, including a 4-ton Leyland at Sheffield, are used in the branches at Liverpool, Brighton, Leeds, Northampton, Gloucester, Dublin, etc., these branches operating under their original trading names. The work in the London area is graded according to the type of transport. For instance, for the horses, of which a number is still employed, the limit of delivery is within a two-mile radius, for the electric vans four miles, and beyond that the petrol vehicles are employed.

In view of the controversy which had been raging for some time in connection with the use of pneumatic tyres on heavy vehicles, it is of interest to note that the company are fully convinced that pnetLmatic tyres are infinitely better, even for vehiTles of 31-ton capacity. This is well shown by the experience with their two 3i-ton De Dions, one of these running on solids and the other on prieu-ma tics.

Considering the tyres alone, pneumatics are naturally Considerably more expensive, but this is more than offset by what is gained by the reduction in the cost of overhauling and by obtaining better running from every point of view. In the case of the De Dior's, both of which were put into service at the same time, these were stripped after running for three years. In the case of the pneumatictyred vehicle, replacements costing D. 8s. 8d. were fitted, and this more because the opportunity was a favourable one than by reason of real necessity. In the case of the solid-tyred vehicle, the cost of replacements amounted to 125, and apart from this the body was badly shaken, costing an additional £10 for repair. Besides this there was actually a difference of £30 to the advantage of the pneumatictyred vehicle in the cost of dismantling and fitting, and it was proved that the stripping of the latter vehicle need not have been carried out before a: further considerable period of use.