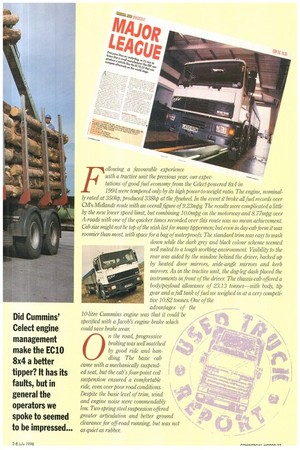

Did Cummins' Celect engine management make the EC10 8x4 a

Page 39

Page 38

Page 40

Page 41

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

better tipper? It has its faults, but in general the operators we spoke to seemed to be impressed...

• When it comes to new technology, road hauliers are notoriously conservative: they are naturally reluctant to pick up and run with anything that might prove unreliable unless there is at least the promise of some financial advantage. The growth of electronic management/diagmostic systems is a case in point Many operators held back, partly because of a fear of the unknown—and the prospect of having to run back to the main dealer every time a minor problem manifested itself.

Before ERF started to enjoy its present success with the Cummins 11-litre engine it introduced a 350hp version of the 10-litre L10 with Cummins' Celect engine management system, which would be needed further down the line to conform to emission regulations.

• EVOLUTION

In a tipper environment the 325hp version of the L10 engine had long been appreciated for its high power, light weight, longevity and Following a favourable experience with a tractive unit the previous year, our expectations of good fuel economy from the Celect-powered 8x4 in 1994 were tempered only by its high power-to-weight ratio. The engine, nominally rated at 350hp, produced 338hp at the flywheel In the event it broke all fuel records over CM's Midlands route with an overall figure of 9.23mpg The results were complicated a little by the new lower speed limit, but combining 10.0mpg on the motorway and 8.77mpg over A-roads with one of the quicker times recorded over this route was no mean achievement. Cab size might not be top of the wish list for many tippennen; but even in day-cab form it was roomier than most, with space for a bag of waterproofs The standard trim was easy to wash down while the dark grey and black colour scheme seemed well suited to a tough working environment. Visibility to the rear was aided by the window behind the driver, backed up by heated door mirrors, wide-angle mirrors and kerb mirrors. As in the tractive unit, the dog-leg dash placed the instruments in front of the driver The chassis-cab offered a body/payload allowance of 23.13 tonnes—with body, tip gear and a full tank of fuel we weighed in at a very competitive 10.82 tonnes One of the

advantages of the 10-litre Cummins engine was that it could be specified with a Jacob's engine brake which could save brake wear

On the road, progressive braking was well matched by good ride and handling The basic cab I i came with a mechanically suspendf ed seat, but the cab's four-point coil 1 suspension ensured a comfortable ride, even over poor road condition& Despite the basic level of trim, wind and engine noise were commendably low Two-spring steel suspension offered \ greater articulation and better ground clearance for off-road running, but was not as quiet as rubber litre unit without sacrificing some reliability, but early in 1993 Cummins introduced a 350hp variant which combined electronically controlled injectors with a full engine management system.

With a number of sensors placed around the engine, the Celect system was not only able to give early warning of impending problems; it also served as a speed limiter and cruise control while adjusting the amount of fuel injected to suit engine load.

The system had been in operation for some time in the US where any bugs had long been sorted. ERF certainly had few doubts about it, and the Euro-1 350hp unit made an ideal high-power option for ERF's newly introduced EC range.

The EC cab was constructed in a similar manner to the earlier E-Series, using sheet moulded compound (SMC) panels on a steel frame. But the new design, with its deeper laminated windscreen, was heavier than the E-Series. So although operators may have wanted the extra power, they were not prepared to sacrifice too much payload.

Along with the improved trim, instrumentation included a Road Relay display which provided the driver with real-time engine performance data, including an instantaneous

fuel-consumption readout. Transmissions included a choice of synchromesh, constantmesh and even a semi-automatic gearbox.

There was also a choice of suspensions, but it soon became clear that the low-maintenance qualities of the rubber suspension would prove popular for on/off-road operations with the double-drive axles at the rear of the chassis.

• OPERATORS

Adrian Watt, commercial director for Kenny Transport of Peterborough, runs a mixed fleet of about 85 artics and rigids including 11 8x4 tippers. The company was a founder-member of Palletline, a consortium of more than 40 hauliers which operates a national network for palletised goods in a shared-user multi-drop operation.

"The eight-leggers work on a dedicated contract for 13ardon Aggregates," he says. "Most are Fodens with Cat or Cummins L10 325 engines. We have just one ERF 8x4, and that is powered by the Cummins 350 Celect engine. We bought it almost three years ago; at the time the price was a bit better than Foden's. ERF uses the same major components, and unladen weight is about the same. I believe ERF still offers a price advantage. They are plated at 31 tonnes, which gives us a payload of 20.2 tonnes. As most mad gangs order in 20-tonne increments this suits our operation."

Watt keeps comprehensive operational records. At the touch of a button he shows us that the EC10 350 averaged 8.5mpg over the past 12 months, compared with 8.12mpg from the 325 Cummins powered Fodens. "They all cover about 100,000km a year and over that distance any difference in the work evens out," he points out. "That's a saving of 340 gallons so there's no doubt that the electronic engine is more economical than the 325, but it's matched by trucks fitted with the 270 Cat engine. Mechanical injection can give good results for set load conditions but the electronics adapt to whatever the load conditions are. We run fully laden for about two-thirds of the time.

"The in-cab display can act as a driving coach to improve driving style and reduce fuel consumption," he adds. "I encourage my drivers to keep engine speed within the sweet spot and avoid idling for excessive periods. In the past we have held onto our eight-wheelers for 10 years—that is most definitely more economical than changing them at an earlier stage. However, our purchasing policy is under review as our customer has a preference for newer vehicles. The proposal is to replace after six years and we are considering whether to lease or buy outright.

"Residuals are sound for ERF," Watt reports. "They're on a par with the Fodens. We normally sell privately through the pages of CH we expect to get between £7,000 and £8,000 for an 11-year-old Foden we currently have for sale.

"Our next new tipper is a Daf C85 CF with the new 12-litre mechanical-injection engine," he says. "Reports are very good so it's time to try it out We're also taking three ERF 6x2 EC tractive units with the 02 Cat engine. We run

on Michelin and Bridgestone tyres which are no problem: we regularly get 100,000km from the drive axles and 120,000km from those on the steer axles. With experienced drivers the Twin Splitter gearbox is the best there is, but there is a downside if we have to use agency drivers. Rubber is specified at the rear. We have never had a problem from the Foden's suspension so we expect the same for the ERR If Autolube isn't fitted as standard we fit it ourselves—it keeps maintenance costs down to the minimum. Our own workshops are open for 20 hours a day. The trucks get an inspection every 7,000km, which is important, especially with regard to the brakes. Only the later ones have automatic adjusters, but even they need to be kept free.

"The cab is standing up to the wear well," he says, "but the seats are rubbish. The covers are poor quality and only lasted just beyond the two-year warranty period. ERF parts prices are cheaper than most and we source some for our MANs, Dafs, Renaults and Fodens through the local ERF dealer. Some last longer than others so parts costs on an annual basis is the truer measure. The EC10 350 works out about the same as for the Foden 8x4s."

Richard Lineker has been an owner-driver for six years and works under contract to La Farge Ennemix. "I had a Mercedes-Benz 3229K for the first three years," he says. "It was too heavy on fuel, weighed over 11 tonnes and was always breaking down. Parts were expensive too. I needed to change it and Ennemix had a policy of buying ERFs at the time. The other lads on the contract spoke well of their trucks. The electronic engine management could have put me off the 350 but in fact it was the reverse. The price of the ECM worked out a little bit dearer than the equivalent Scania, Volvo or Daf, but I felt it gave value for money.

"We deliver aggregates over a 90-mile radius from Nottingham," says Lineker. "My truck was specified with a Wilcox alloy body with Edbm tipping gear, which gives me a payload of 21.4 tonnes running at 32 tonnes gross. I have no trouble getting 9.5mpg and, depending on the terrain and wind conditions, I can get as much as 10.5mpg. The fuel-consumption gauge on the Road Relay display certainly helps to keep running costs down.

"I have it on a five-year lease-purchase agreement so I'm looking to keep it for six. ERFs hold their price better than MercedesBenz," he adds. "I've had my share of troubles, but tyre life is excellent. The rears lasted for 125,000km and the fronts were changed at 75,000km. The linings came away from the shoes on both rear and the second steer axles but the fronts are still original at 352,000km after two-and-a-half years.

"When the engine fuel shut-off valve packed up I couldn't shut down the engine on the switch so I just stalled it," he recalls. "The viscous coupling locked up and I have had the odd bolt drop out of the manifold. The salesman gave me a crash course on the Twin Splitter and I thought it was a real bitch for the first month, but now I wouldn't want anything else. ERF had to replace the fourth axle because the welding cracked around the rear casing. They tried to weld it up at first but it kept leaking oil. The window lift switches last about five months before they burn out. They're £16 a time but I carry a spare with me so I don't get drenched in the wash on the way out of the quarry. It's on its fourth radio. The Clarion just wasn't man enough—I've got a Phillips now. Bushes in the A-frame over the rear axles disintegrated after two years and two months. The parts cost £721 and it was just out of warranty. They should be good for at least six years so lam still talking to Toptrux about it.

"The base to the seat wears quickly," says Lineker. "I've already replaced one cover. The front bumper got damaged when a fork lift

backed into it. 40 The replace

ment is painted, but not very well as it's peel ing after just one month. The main sup

port tube on the Eminox vertical exhaust stack is forever breaking It's made of cast alloy and doesn't last more than a month. Eminox says it must be fitted wrongly but all the other lads have the same problem. The replacement kit with all the brackets is £80. Nevertheless fuel consumption and payload make it a good truck to run and it's cheaper to buy parts from ERF than a factor.

"The rubber suspension doesn't articulate as well as a steel-sprung bogie," he adds, "but with cross-lock and inter-axle locks the EC10 goes in and out of places that I couldn't have taken the 3229K. Mirrors get filthy on rainy days and 1 am for ever wiping them. One thing that really annoys me is the passenger door. It doesn't have an external lock so I have to climb over the engine when I want to open it to let someone in."

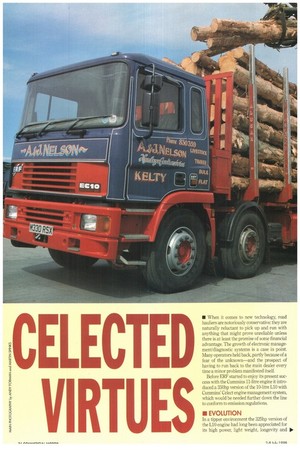

Sandy Nelson might be described as a committed ERF man: 46 of his 50 trucks come from Sandbach. There are 36 tippers, working mainly on bulk grain, agricultural and forestry operations from AJ Nelson's base at Kelty, just north of the Fourth of Firth. Four of Nelson's eight-wheelers are equipped with Cummins 350 Celect engines.

"I started with one Gardner-powered ERF back in 1970," he says. "I've stayed mainly with them ever since. The EC10 350s are two to three years old and have averaged about 65,000 miles a year. Two of them, used on logging, have a lot of standing time. They load and unload themselves so they use the most fuel, between 6.7 and 7.2mpg. One's a bulker with a blower, and that returns about 8.2mpg. The fourth is a general-purpose vehicle with removable body side panels so it can be used as a flat or cattle float as well as a tipper. It's under-loaded more often than not, and it's the best at 8.7mpg.

"Generally I have been extremely pleased with reliability, although ERFs can be hard on brakes," Nelson adds. "The Twin Splitter transmission is first class. We have rubber suspension on almost all of our eightwheelers and it does well in most respects. Elephant feet need replacing now and then but they never just go like steel springs. They're not difficult to change and are not too expensive. The bushes on the A-frame are not bad. Again, we get the odd one going, but we expect them to last three years on logging.

"The chassis has never been a problem for us, but if the EC cab has a fault it is with the mountings—they don't stand up as long as they should," he says. "Door locks have been a painful item over the years; they fill with dirt and stick. Cab seats are not the best either. I've had a couple of the tractive units where the looms have been replaced, but the electrics haven't been any trouble on these eight wheelers. Back-up from my local dealer is first class. Parts prices keep creeping up, but they're still competitive.

"I'm going to try the 12-litre Cat engine

in my next eight-wheeler," Nelson remarks. "We like to keep them for about six years but second-hand sales have not been good lately so we still have one or two older ones. There are a lot of trucks for sale out there; not just ERFs but all makes. Discounting and guaranteed buy-back schemes initiated by the manufacturers have increased the number of younger used vehicles coming into the market place at a lower cost, and this is depressing the sales of older vehicles. Residual values are definitely down."

• DEALERS

Dave Allen is sales director for used trucks at the Toptrux ERF franchise in Nottingham. The used-truck division was set up to handle the resale of vehicles taken in part-exchange by the company's ERF and Mercedes-Benz outlets. Toptrux has a turnover of some 250 used vehicles a year, covering most makes and models ranging from 3.5-tonne vans to 38tonne tractive units.

"The EC was only in production for a couple of years with Cummins' L10 engine from 1994 before it was replaced with the M11," says Allen. "The L10 325 was much more commonly found in the eight-wheeler, and although the 350hp Celect engine was more popular in the EC tractive units it was pretty rare in the 8x4 rigid chassis. The eight-wheeler market for new vehicles as a whole has been at a low ebb for quite a few years."

ERF was fourth strongest in the four-axle market in 1994; it took just over 10% with 264 units. "Tipper operators buying new trucks tend to keep them for longer than operators of tractive units do," he points out. "Five to eight years is not unusual. Combine that with the low numbers sold initially and you can see there are not going to be many EC10 350 Celect 8x4s available in the used truck market.

I can't say that I've seen one, although we have sold a few with the 325hp engine. The EC cab is excellent for tipper work. Rubber suspension was the popular choice for the EC 10 8x4; it's cost-effective with low maintenance costs. Autolube is a popular option for the same reason.

"A lot of new trucks are being sold today for less than they were three to five years ago," says Allen. "That's having a serious knock-on effect on the value of five and six-year-old vehicles, although the market for specialised vehicles is holding up better. We've just sold a 12-month-old EC11 340 for £50,000, while an M-reg 1995 EC10 325 8x4 sold for £32,000. If you can find one, expect to pay about £2,500 more for the 350hp Celect."

II INSURANCE

Roberts Davis of Norwich gives an insurance quote of £733 based on UK-only hire-andreward for a mature owner-driver with maximum no-claims discount. This cover does not include tipping risks.

• SUMMARY

For two years the EC10 350 took the minor share of 8x4 production. The Celect was the first of ERF's electronic management engines and is the forerunner to the M11: it gave good fuel economy. No commercial vehicle, particularly one working in a rugged off-road environment, is going to be fault-free. But even users who have encountered problems remain impressed with this model's productivity The cab is certainly comfortable and practical, though there may be doubts over the life expectancy of the trim.

The Cummins Celect engine has proved itself more than capable of surviving and thriving in a rugged tipping environment; dealer back-up and spares prices earned widespread praise.

Used examples are thin on the ground, and residuals are strong, but if one comes your way it's definitely worth a second look.

0 by Bill Brock

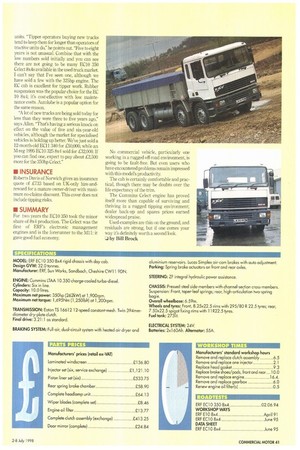

SPECIFICATIONS

MODEL: ERF EC 10 350 8x4 rigid chassis with day cab. Design GVW: 32.0 tonnes.

Manufacturer: ERF, Sun Works, Sandbach, Cheshire CW11 9DN.

ENGINE: Cummins LTAA 10.350 charge-cooled turbo-diesel. Cylinders: Six in line.

Capacity: 10.0 litres.

Maximum net power: 350hp (262kW) at 1,900rpm. Maximum net torque: 1,69.5Nm (1,250Ibft) at 1,200rpm.

TRANSMISSION: Eaton TS 16612 12-speed constant-mesh. Twin 394mmdiameter dry-plate clutch. Final drive: 3.21:1 as standard.

BRAKING SYSTEM: Full-air, dual-circuit system with heated air dryer and

aluminium reservoirs. Lucas Simplex air-cam brakes with auto adjustment, Parking: Spring brake actuators on front and rear axles.

STEERING: ZF integral hydraulic power assistance.

CHASSIS: Pressed-steel side-members with channel-section cross-members. Suspension: Front, taper-leaf springs; rear, high-articulation two-spring bogie.

Overall wheelbase: 6.59m.

Wheels and tyres: Front, 8.25x22.5 rims with 295/80 R 22.5 tyres; rear, 7.50x22.5 spigot fixing rims with 11R22.5 tyres. Fuel tank: 273Iit.

ELECTRICAL SYSTEM: 24V.

Batteries: 2x160Ah. Alternator: 55A.

PARTS PRICES

Manufacturers' prices (retail ex-VAT) Laminated windscreen £136.80 Injector set (six, service exchange) £1,121.10 Piston liner set (six) £533.75 Rear spring brake chamber £58.90 Complete headlamp unit £64.13 Wiper blades (complete set) £8.46 Engine oil filter £13.77 Complete clutch assembly (exchange) £413.25 Door mirror (complete) £24.84

WORKSHOP TIMES

Manufacturers' standard workshop hours Remove and replace clutch assembly 6.5 Remove and replace one injector 2.1 Replace head gasket 9.3 Replace brake shoes/pads, front and rear....10.0 Remove and replace engine 16.4. Remove and replace gearbox 6.0 Renew engine oil filter(s) 0.5

ROADTESTS

ERF EC10 350 8x4 02.06.94 WORKSHOP WAYS ERF El0 8x4 April 91 ERF EC10 8x4 June 95 DATA SHEET ERF EC10 8x4 June 95