FOLLOWERS OF FASHION

Page 53

Page 54

If you've noticed an error in this article please click here to report it so we can fix it.

Daly Transport is a high quality haulage group specialising in a market where the bottom line is always in fashion — the rag trade. How does it survive so well?

• To most people, the rag trade conjures up transience, ramshaclde sweat shops and company liquidations. To the transport industry, garment haulage has just about the same image.

It is a precarious business, full of "here today, gone tomorrow" haulage firms and big name casualties. Some of the major names which have had their fingers burnt in the garment industry recently are Birkhart, Gerald Henry and P&O Fashionflow — they all went to the wall.

Large retail groups with their own transport arms, such as Burtons High Street Transport, are currently dominating the scene. They enjoy consistent and assured workflows. The other big boys, like TNT Garment Express and Bunzl's Scorpio operation, have high profiles and good client lists. Tibbet and Britten for instance, relies on one client — Marks and Spencer — for more than 70% of its workload. The small guys are left to scramble around picking up the crumbs from the table.

Daly Transport Services (DTS) is a rare thing in this viciously priced market — a rising force, coming up through the ranks.

The company is based in Homsey, North London, right in the heart of the capital's clothes belt, accessible to the West End, the M1 and the M25. In just over seven years DTS has grown from a one-man-andhis-van outfit to a group employing 120 people and running 30 vehicles. Last year it shifted 20 million garments — 500,000 to 700,000 garments a week during peak periods.

Daly's current premises are its third and, ironically, they are adjacent to those previously used by Fashionflow. 'Mere is still room for expansion; in the past 18 months DTS has gone from two to five industrial units on the site.

Garment haulage is the sort of market which dictates a flexible and responsive transport system, and Daly has had this in mind from day one. Much of the company's work involves picking up clothes from the workshops of small manufacturers, consolidating the different pick-ups together at its warehouses in Homsey, and then making bulk deliveries to the distribution centres of the large retail chains.

Fashion buyers work on short delivery dates and they need to get their products on the shelves within a couple of weeks. If they wait any longer, says DTS managing director Mike Daly, the garments become almost worthless: "It is not the intrinsic qualities of the clothes that are worth money, it is their contemporary design. The cloth itself is pretty cheap."

The rag trade is booming at the moment. DTS clients include C&A, French Connection, Top Shop, Fred Perry and Debenhams. It has more than 400 customers on its books and although most of the group's business is "spot work" — phoned in about seven days in advance on average — there are predictable peaks around Christmas and just before Easter.

To meet demand DTS offers customers 4,645m2 of warehouse space, most of which is designed to allow hanging garments to be stored ready for rapid callout. Daly refuses to put all of its eggs in one basket and it does not work "exclusively" for anyone. One of DTS' clients, the mail order catalogue Freemans, keeps work flowing all-year-round and helps

fill in the seasonal gaps. DTS handles several million Freernans garments every year, and Freemans uses Daly's entire range of services, which includes storing cloth in rolls, garment labelling, packing, ticketing, quality control inspection and even repairing "Diversification is the route to survival," says Daly.

One of DTS's most important functions is stock control, and weekly reports are prepared. There is a fully computerised monitoring service controlling the system, and a client can be told in less than four minutes exactly where any of its goods are in the DTS pipeline. The Amstrad computer is also used for keeping tabs on the accounts, on vehicle maintenance and servicing, routeing and scheduling work.

The routeing program works for all sizes of truck and gives the fastest, shortest and cheapest routes available based on Department of Transport statistics. The drivers each get a print-out of where they have to go because Daly rarely has return loads, and in a market where time really is money, fleet utilisation must be maximised. Fleet and traffic managers work a two-shift day, every day.

GOOD PERSONNEL

Daly believes that good personnel are essential. The drivers get £4.15 an hour plus overtime and allowances in the Class One HGV band and, according to Daly, "they just don't leave". The company has also just taken on Alan Nordwin, with 18 years experience in the industry, latterly with Tibbet and Britten as traffic manager.

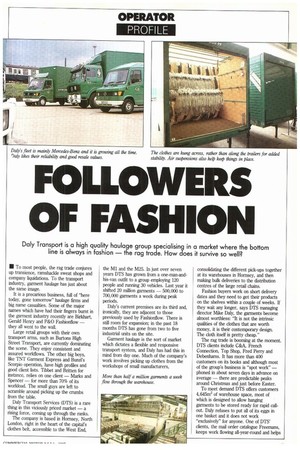

Fashion is an image-conscious business, and Daly aims to try and keep pace with its customers. The company livery is green, and it is everywhere, right down to the drivers' T-shirts and the furniture and fittings in the office. Targetted give-aways are also used extensively.

The vehicles keep up the image of speed and quality. They are all well maintained, green Mercedes. Daly reckons that the units cost him about 15% more than competitive vehicles, but their reliability is good. Fuel consumption has been disappointing on the smaller 307D vans, but generally the fleet serves him well and the company gets good resale values when it sells of the vehicles every four to five years.

Preventative maintenance and regular servicing is carried out to the manufacturers' letter in Daly's small workshops. There is no engine hoist in the bay because, according to Daly, "we don't have to replace engines".

Body strength is very important to DTS too, because it places its hanging garment rails across rather than along the bodies. They can be adjusted to different heights to maximise the loading space. Most of the 307Ds are boxed, though there are a few panel vans for getting in and out of confined urban yards.

DTS also runs Mercedes 814s with 6m bodies, and four heavier rigids — two Mercedes 1617s and two 1625. These run with Ray Smith demountable bodies and drawbar trailers. The units cost Daly about 1'70,000 — hardly cheap, but the company appreciates their greater carrying capacity, especially when compared to a 12.2m artic combination. Daly plates at 28 tonnes, as garment haulage is all volume and no weight. A trio of artics and six 12m trailers are used for emergency work. They tend to get parked up first, however.

All of the heavier units are fitted with air suspension, "because it stops the garments jolting off the rails", says Daly. "Customers don't like their goods arriving in a crumpled heap." The artic trailers were bought second hand from John Lewis.

RADIO CONTROLLED

Just to make sure Mercedes does not get complacent, DTS has recently bought a Daf tractive unit. All of the fleet's larger trucks have cabphones, and the smaller units are radio controlled. There is even a motorbike despatch rider on the fleet to carry urgent fabric samples around.

DTS group turnover is moving towards the £3 million mark at present and Daly has his sights on becoming one of the country's top three garment hauliers. It has been a tough battle to grow in such a cut-throat business and Daly admits that in the past he found it difficult to delegate. Now, he says, "I manage the managers".

He has made a few mistakes on the way. With property prices rocketing in the South East, he wishes that he had bought his warehouses sooner. He describes his old financial advisers as "parochial" and "suburban" and today he shares his advisers with Sir Terence Conran's British Home Stores group.

Moving his account to a merchant bank rather than the bank around the corner was a good move too, he says. Credit control systems have had to be tightened recently, to keep the financial edge sharp.

Keen pricing will remain the group's guiding light. In most industries, distribution is costed at about 5% of turnover. In the fashion industry, it is around 1%. Our future will be "based on attracting long term customers," says Daly, "so we don't screw people on price."

by Dave Young.