MOBILITY FOR THE DEMOLITION PLANT

Page 64

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

TT is not so very long ago ithat rock-breaking and demolition Work were executed only by explosives and by manual labour with the aid of the sledge-hammer. There was no question of the conveyance of picks, crowbars and hammers. Nowadays, however, theke operations are performed speedily by pneumatic tools, and the power which they demand is supplied by heavy motor engines and air compressors. These must be conveyed to the scene of action—often in great haste.

A company whieh has grown contemporaneously with the development in the use of Power for demolition Work is the Demolition and Construction Co., Ltd., of 74, Victoria Street, Loudon, SAVA, and the different means which

this concern, employs for its transport afford an interesting study in the use of commercial vehicles.

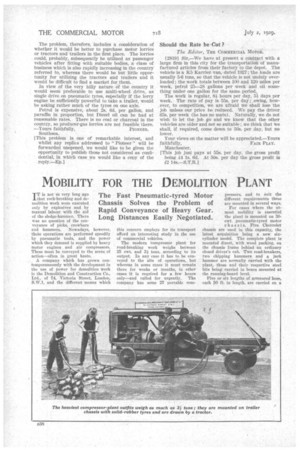

The modern t ompressor plant for road-breaking work weighs between 25 cwt. and ai tons, according to its output. In any case it has to be conveyed to the site of operations, but whereas in some eases it must remain there for weeks or months, in other cases it is required for a few hours only—and called for urgently. The company has some 27 portable cora

pressors, and to suit the different requirements these are mounted in several ways.

For eases where the utmost mobility is essential the plant is mounted on 30cwt. pneumatic-tyred motor chassi s. Five Chevrolet chassis are used in this capacity, the latest acquisition being a new sixcylinder model. The complete plant is mounted direct, with wood packing, on the chassis frame behind an ordinary closed driver's cab. Two road-breakers, two chipping hammers and a jack hammer are normally carried with the plant, these and their respective steel bits being carried in boxes mounted at the running-board level.

Five or six lengths of armoured hose, each 50 ft. in length, are carried on a

stout bracket behind the cab, and a box containing steel bits is mounted on each side. A shelf behind the cab accommodates six two-gallon cans of petrol and one of lubricant. On the roof of the cab are the spare wheel and a tarpaulin for use at night-time when the plant is exposed. The machines thus equipped are capable of long and fast road journeys, and undertake work regularly inall parts of England, Scotland and Wales.

It will be -understood that during the time when these machines are engaged in demolition work they involve the profitless inactivity of road power units, and for this reason a different means for transporting the compressor has to be devised for work which entails the long delay on one site of the compressor plant and equipment. '

The Demolition and Construction Co., Ltd., 'overcomes this difficulty in three ways. Four of the heavier compressor outfits are mounted on specially constructed drop-frame trailer chassis having solid tyres, the complete unit weighing about four tons. This can b e hauled either by a Dennis 1922 three-to.n lorry, which the cgonpany has had in use for several years and employs for carrying its Pneumatic h a m mere and other gear, or by an International pneumatic tyred tractor which the company purchased 12 months ago.

The heavy solidtyred trailer outfit cannot be drawn at a great pace, and for faster journeys the company has a Carrimore 30-cwt. trailer mounted on 30in. by 5-in, pneumatic tyres. This vebicle has brakes on its rear wheels which are operated by a cable that can be bitched to actuating gear on either the Dennis lorry or the International tractor, and it is capable of carrying one of the smaller compressors, together with several pneumatic tools, at a speed of 20-25 m.p.h. The compressor plant, mounted on a simple iron frame with small iron wheels, may be set down on the site, a hinged ramp and hand-operated winch being„ mounted on the trailer to facilitate this, and the Dennis and trailer may then proceed to undertake other useful work.

The third method of conveying compressor plant consists of a much larger Carrimore trailer with a load capacity of five tons. This unit, drawn by the International tractor, does not permit road speeds to be obtained equal to those of the smaller trailer, but it is extremely useful when the heaviest compressors and a' large amount of rock-drilling and road-breaking plant has to be carried. The big trailer has solid-rubber tyres, and its overall length mid width are 20 ft. .4 ins. and 7 ft. 2 ins, respectively.

The floor height is 2 ft, 10i ins., so that loading of the plant is not a difficult matter. For this purpose two channel-sectioned steel, ramps hook on to the rear of the trailer, and the plant is hauled aboard by a handoperated winch mounted at the forward end. It is a common occurrence for this vehicle to convey, its addition to the largest Ingersoll-Rand compressor plant, six of the heaviest tripodtype rock drills, a dozen paving breakers, several jack hammers, a petroldriven Miller's concrete mixer, and a quantity of timber and expanded metal.

The maintenance of all these machines is undertaken at the company's depot at Hammer smith, where some very interesting plant is to be seen. This includes the aforementioned rock drills, special plant for chipping old paint off steel bridges and for grinding railway tracks, etc.