Light footed 6x2

Page 31

Page 32

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

The impressivelly low kerb weight of Seddon Atkinson's 301 6x2 tractive unit gives it exceptional payload potential. Bryan Jarvis puts it through its paces

WHEN 38 tonnes became legal on British roads initial demand was for tri-axle semi-trailers, but it did not take the manufacturers long to recognise the sales potential for six-wheel tractive units.

Some foreign manufacturers such as MAN and Daimler-Benz had models produced for their home markets which were readily available. Others moved quickly into production.

Seddon Atkinson was slow to join the 6x2 fraternity, hampered no doubt by the uncertainty over its future. But when it did enter the fray it upheld its reputation for building vehicles with extremely low kerb weights.

Both of its 301 and 401 ranges have three-axled versions available for 38-tonne gross combination weight use. The latter, which can be supplied with either Cummins, Gardner or Rolls-Royce engines of 300hp plus, is well suited for continuous multi-shift work. The 301 models, one of which is the subject of this week's road test, have the reputable Cummins 10-litre engine.

Originally offered at 180kW (241hp), the 301 now has the turbocharged and chargecooled engine rated at 208kW (278hp), giving it a 5.47kW/tonne (7.4hp/ton) power-toweight ratio at 38 tonnes.

Matching the compact Cummins engine to the 301 cab with its low-installed height makes for a neat installation, but, more importantly, its performance is very well suited to the Spicer SST1310-4A 10apeed gearbox and Rockwell R180 rear axle drivetrain.

In fairly mixed weather condi:ions over the three days of :esting around our 736.8 mile 3cottish route our 301 returned 7.02mpg at a very respectable average speed of 43mph.

On speed it falls some way short of mightier machines such as the 356hp MAN 19.361 4x2 tested last November (CM November 3, 1984) and marginally behind other 6x2s taken around our Scottish route. But for sheer economics it is a first :lass performer.

Seddon Atkinson's 6x2 models have totally different steering and suspension arrangements on the extra axle to those of the two previous 6x2 models tested. (The Scammell has a postively.steered steelsprung system; Volvo's F10 used an air-suspended, selfsteering axle.) The system in the 401 and 301 is something of a compromise. Its intermediate axle has air suspension and is located on parallel steel links. A Panhard rod controls the axle's lateral movement. A Dunlop Pneuride system is used which is controlled by two levelling valves mounted on the drive axle.

Unladen, the valves are inoperative. There is only minimal pressure in the air bags for adequate steering control. As the drive axle load increases the first valve pressurises the air bags to allow the second axle to take a proportionate amount of the load.

When a semi-trailer is uncoupled the system automatically deflates to the residual conanued overleaf pressure. The reverse applies as soon as the weight of the trailer is felt.

As the load increases to 9,445kg (8.5 tons), the second levelling valve allows the air bags to inflate fully so that the vehicle can then be laden to its maximum gross weight. A safety sling is also fitted between the chassis and the axle to limit sudden excessive downward travel. Being a steel cable the extra length causes the sling to bulge.

Knowing this to be a potential problem area, I found that on the nearside the cable was indeed rubbing against the airbag, although the offside cable bowed correctly away from the unit. According to the engineer accompanying the vehicle, Seddon Atkinson is taking the necessary steps to prevent any rubbing.

Steering on the second axle is via an intermediate drop-arm and conventional linkage, with the ZF 8043 steering unit providing sufficient power assistance to cope with the additional axle. Driving around busy Edinburgh was much the same as with a conventional 2+3 combination. Tyre scrub was minimal.

A deflate button for the air system, mounted in the cab is intended to allow the driver to empty the air bags for extra traction. On the test vehicle it was very badly sited in the centre of the dash. It required a full stretch to reach and, be sides being very stiff, it was partly obscured by the fusebox lid handle. I needed to use it quickly on my first attempt at the 1 in 5 test hill at the Motor Industry Research Association test facility and on the climb out of Shotley Bridge. But on each occasion the dump switch had to be operated by my codriver using both hands. Seddon Atkinson is going to fit a timed delay switch closer to the driver, however.

The longer axle spread has increased the turning circle to 17m between kerbs. This is much greater than the 13.6m of the F10 6x2 and the Scammell 6x2's 14.2m. Nevertheless, the 301's twin steering and suspension arrangements works very well. Apart from the Foden 6x4, the 301 certainly felt the most stable of the 6x 2s test so far.

On roundabouts and sharp bends it had very good roll stability while on undulating surfaces such as the two mile run down the B6278 to Shotley Bridge, the suspension gave a firm but well-controlled ride. That type of road also showed up a fair amount of cab movement. It was also apparent on some stretches of the Al where I became a passenger for a short stretch.

In road going trim our test vehicle tipped the scales at 7,280kg (7tons 3.5cwt) which is around 400kg (8cwt) lighter than the Volvo F1026 6x2 road tested early last year (CM April 28, 1984) and 430kg (12.5cwt) less than Leyland's Scammell 2032 which we tried out last October (CM October 27, 1984).

The results of this test show the 301 to have the highest payload capability among the three-axle tractive units tester so far. Its performance however, is not quite as sharr as comparable vehicles at thr maximum gross weight. From ( to 40mph its time of 51.i seconds was 3.5 seconds slower than the 281hp Volvo F1026 and 4.0 seconds behind the Leyland 290hp, 4 x 2 Roadtrain (CM, August 13, 1983).

The 301 6x2's hill climbs were all slightly slower than the Volvo F10 and, apart from a few seconds on Carter Bar, took marginally longer than the Leyland 4x2 Roadtrain too. But this was no disgrace considering the overall average speed and daily journey times. Had it not been for Edinburgh traffic and the poor weather conditions on the last day the average speeds would have been much higher.

For anyone not familiar with the performance of the Cummins 10-litre engine, it is a lively and flexible performer developing its maximum power at 2,100mm and peak toque at 1,300mm.

On motorways it pulled sweetly at 2,000rprn in top at the 60mph limit yet lugged down well on the long grades. Climbing Shap required a drop down to ninth gear, but the road speed held at 40mph with the engine revs right in the centre of the torque band.

Obviously, motorway and dual carriageway running suits the 301's drive line for fuel economy and this is borne out by the excellent returns over the first day and the short journey up the A74/M74 to Hamilton -a total distance of 291.5 miles over which its fuel consumption averaged 7.78mpg.

On the A1/M1 section on the last day the 301 also produced good results, but clearly the difficult section between Roches ter and Neville's Cross took its toll of fuel efficiency. However, it compensated on the hilly stretches with good pulling power and a smooth Spicer gearbox.

Once it became familiar, the Spicer gave a comfortable gear change, whether I used quick whole changes on sharp hills or split-shifts. This can be done either by using the clutch or easing off the throttle to break the torque.

Starting from rest on level roads requires third gear followed by fifth before the splitter is needed for all of the remaining ratios. But on anything of an incline, second gear has to be used, missing third out and using each of the other gears.

Savage gradients such as West Woodburn and Kiln Pit Hill needed careful measure, occasionally quickly dropping two whole gears at a time to maintain good time along the A68.

Driving down towards Shotley Bridge and the much longer descent to the Corbridge bypass quickly exposed the absence of the engine exhauster brake. My concern was heightened especially as I had only recently driven a 401 two-axled unit fitted with a Jacob brake. Although only two thirds of the system had been connected, its performance compared with conventional exhaust brakes had been very impressive.

The 301's brakes and those of the test trailer were effective enough, but towards the bottom the smell of hot linings was very strong. Cummins Turbo brake is not yet available on this particular model, but some form of additional braking should be made a priority.

Seddon Atkinson is working on provision of an exhaust brake, but no decision has yet been reached.

Wet tracks at the MIRA circuit prevented any brake testing and a widespread downpour on the last day left the tyres too wet to carry out roller brake tests.

But before we set out on the Scottish route, several hard applications at up to 40mph speeds had revealed a very satisfactory rate of retardation. This remained throughout the three days.

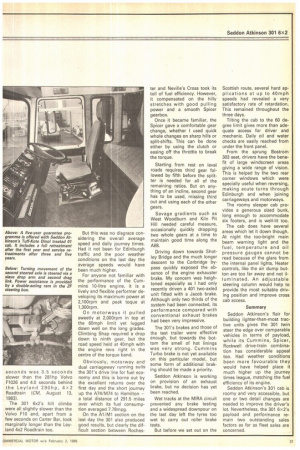

Tilting the cab to the 60 degree limit gives more than adequate access for driver and mechanic. Daily oil and water checks are easily reached from under the front panel.

From the sprung Bostrom 303 seat, drivers have the benefit of large windscreen areas giving a wide range of vision. This is helped by the two rear corner windows which were specially useful when reversing, making acute turns through Edinburgh and when joining carriageways and motorways.

The roomy sleeper cab provides a generous sized bunk, long enough to accommodate six footers, and is well-lit too.

The cab does have several areas which let it down though. At night the too-bright main beam warning light and the fuel, temperature and oil pressure gauges cannot be read because of the glare from the internal panel lights. Heater controls, like the air dump button are too far away and not illuminated. An adjustable steering column would help to provide the most suitable driving position and improve cross cab access.

Summary Seddon Atkinson's flair for building lighter-than-most tractive units gives the 301 twin steer the edge over comparable vehicles in terms of payload, while its Cummins, Spicer, Rockwell drive-train combination has considerable appeal too. Had weather conditions been more favourable they would have helped place it much higher up the journey times league, matching the fuel efficiency of its engine.

Seddon Atkinson's 301 cab is roomy and very accessible, but one or two detail changes are needed to improve the driver's lot. Nevertheless, the 301 6x2's payload and performance remain two outstanding sales factors as far as fleet sales are concerned.