A Jig-built Conversion Unit

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

Details of Dyson Rigid-sixwheeler Extension Unit for Heavy Vehicles, which can be Fitted by Operators

A GOOD many users of four-wheeled .t-1. lorries, such as the Leyland Bull and the A.E.C. Mammoth, are finding it advisable to convert their machines into rigid six-wheelers in order to avoid infringement of the axleweight regulations, and thus to eliminate the risk of unfavourable attention by the licensing authorities under the new Road and Rail Traffic Act. Many are finding it necessary to carry a bigger load so as to. offset the increased taxation.

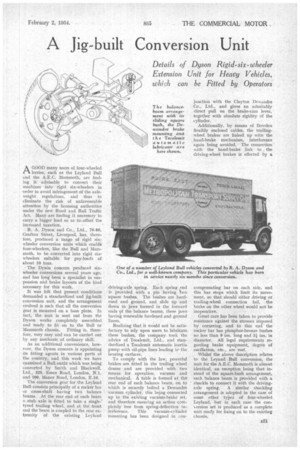

R. A. Dyson and Co., Ltd., 76-80, Grafton Street, Liverpool, has, therefore, produced a range of rigid sixwheeler conversion units which enable four-wheelers, like the Bull and Mammoth, to be converted into rigid sixwheelers suitable for pay-loads of about 10 tons. The Dyson concern produced sixwheeler conversions several years ago, and has long been a specialist in suspension and braise layouts of the kind necessary for this work.

It was felt that present conditions demanded a standardized and jig-built conversion unit, and the arrangement evolved is such that all the conversion gear is mounted on a base plate. In fact, the unit is sent out from the Dyson works completely assembled and ready to fit on to the Bull or Mammoth chassis. Fitting is, therefore, very easy and can be carried out by any mechanic of ordinary skill.

As an additional convenience, however, the Dyson concern is appointing its fitting agents in various parts of the country, and this week we have examined a Bull, outfit which was being converted by Smith and Blackwell, Ltd., 325, Essex Road, London, N.1, and 100, Manor Road, London, E.10.

The conversion gear for the Leyland Bull consists principally of a rocker bar or cross-shaft having two balance beams. At the rear end of each beam .stab axle is fitted to take a single: tyred trailing wheel, and at the front end the beam is coupled to the rear extremity of the existing Leyland driving-axle spring. Each spring end is provided with a pin having /Iwo square bushes. The bushes are hardened and ground, and slide up and down in jaws formed in the forward ends of the balance beams, these jaws having renewable hardened and ground Realizing that it would not be satisfactory to rely upon users to lubritatc. these bushes, the company took the advice of Tecalemit, Ltd., and standardized a Tecalemit automatic inertia pumpwith oil-pipe lines leading to the bearing surfaces.

To comply with the law, powerful brakes are fitted in the trailing wheel drums and are provided with two means for operation, vacuum and mechanical. A table is formed at therear end of each balance beam, on to which is securely bolted a Dewandre vacuum cylindei, this being connected up to the existing vacuum-brake set, and therefore ensuring an action completely free froth spring-deflection interference. This vacuum-cylinder mounting has been designed in eon

junction with the Clayton Dewandre Co., Ltd., and gives an admirably direct pull on the brake-cam lever, together with absolute rigidity of the cylinder.

Additionally, by means of Bowden flexibly enclosed cables, the trailingwheel brakes are .linked up with the hand-brake mechanism, interference again being avoided. The connection with the hand-brake link tothe driving-wheel brakes is effected by a

compensating bar on each side,, and this has stops which limit its movement, so that should either driving or trailing-wheel connection fail, the brake on the other wheel would not be inoperative.

Great care has been taken to provide resistance against the stresses imposed by cornering, and to this end the rocker bar has phosphor-bronze bushes no less than 9 ins, long and 31 ins, in diameter. All legal requirements regarding brake equipment, degree of oscillation, etc., are met.

Whilst the above description relates to the Leyand Bull conversion, the unit for the A.E.C. Mammoth is almost identical, an exception being that instead of the square-bush arrangement, each balance beam is provided with a shackle to connect it with the drivingaxle spring. A similar shackling arrangement is adopted in the case of some other types of four-wheeled Leyland, but in each case the conversion set is produced as a complete unit ready for fixing on to the existing chassis,