Hot Rolled Gears.'

Page 5

Page 6

If you've noticed an error in this article please click here to report it so we can fix it.

A Possible Method of Reducing the Cost of Production for All Kinds of Toothed Gearing.

Nearly four years ago, when the automobile indastry was expanding by leaps and bounds and the capacity of machine tools was the limiting feature, my attention was called to the fact that the shortage of gear cutting machinery seemed to be the greatest. It was then that I conceived the idea of rolling the teeth in the rough blank hot, which idea upon investigation I found was not new, but had never been developed to a practical point. As to the development of the art, investigation brought. fo light the following facts :

The knurling process was always used theretofore, that is, either the die was driven and the blank allowed to turn from its contact with the die, or the blank driven and the die allowed to turn from contact. The idea of rolling gear teeth in a blank first originated with John Comly as early as 1872. Calmly shows the die driven and the heated blank rotating by contact. (Fig. 1). F. A. Brun, a Frem.hman, in 190:5, showed the construction illustrated in Fig. 2; the blank being driven by frictional contact from conical rolls, and the die allowed to turn from contact with the blank. Brun took care of the surplus metal by the adjustment of the conical rolls, the idea being to force this extra metal down into the web of the gears. Chas. H. Logue, who has written a treatise on gearing, experimented with rolling gears; but his method was to take the blank and notch or rough it on a milling or hohbing machine, which gave the correct number of teeth and spao Paper on the hot rolling of gears for use in 4ransmigaions and other automobile work, by II. N. Andereon, member of the Society or Ai, tactile read at the winter meeting, 11th and 12th .Trtn..Jary, 1211. c,, 11,:a from The Automobile," of New York.

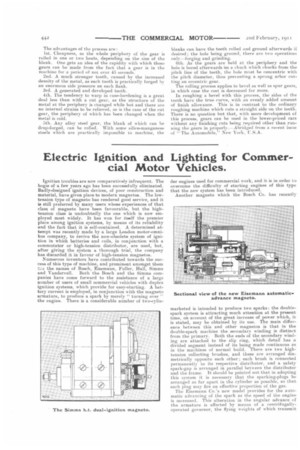

tog; then taking the blank, heating it, and rolling the teeth to form. These operations would be more expensive than cutting the teeth to size in. the first place. 1 then built a small machine and experimented with rolling lead blanks, as the cold lead would flow the same as steel at a forging heat and required but a small amount of pressure. This showed conclusively that the tooth would form itself correctly. A large experimental machine was then built and steel gears were rolled successfully. The machine in itself is very simple, as shown in the plan view. Fig. 3 shows that the driven shaft drives a layshaft (0) through the gearwheels A and B. On one end of this layshaft (C) is the breaking-down or roughing Pig. 5. The machine here shown has been successfully employed by the author.

gearwheel (IS). On the shaft E is the finished gear F, and a timing gear (0) which drives the gear H. The gear H is the same size as the blank to be rolled. This blank, marked J, is held between two chucks (K and L), which are opened and closed by a screw. The whole carriage (M), carrying both chuck and gear, is pivoted on a pin in line with edge of the gear H, and the carriage is oscillated by means of a screw (N) and hanclwheel (F).

The process is as follows; the blank (J) is inserted and the carriage is thrown over to-ward the breakdown gear (D), which does the roughing work. This operation is very interesting, as the blank to be rolled is slightly larger than the pitch diameter of the gear, the metal being broken up by this breakdown gear and then " flowed " out to a larger diameter. The blank is next brought into contact with the finishing gear (F), and. carried up until the carriage reaches a stop (S); then the proper depth of tooth is reached and also the proper diameter, at the same time the surplus metal thrown out on the end of the teeth is trimmed off by a cutter (1)_ The wheel is brought into contact with the cutters by the movement of the pivoted carriage. The gear is kept in this machine until it takes a permanent set, and is pushed off the holding arbor by a stripping device which cannot distort it. The advantages of the process are 1st. Cheapness, as the whole periphery of the gear is rolled in one or two heats, depending on the size of the blank. One gets an idea of the rapidity with which these gears can be made from the fact that a gear is in the machine for a period of not over 43 seconds.

2nd. A much stronger tooth, caused by the increased density of the metal, as each tooth is practically forged by an enormous side pressure on each flank.

3rd. A generated and developed tooth. 4th. The tendency to warp in case-hardening is a great deal less than with a cut gear, as the structure of the metal at the periphery is changed while hot and there are no internal strains to be relieved, as is the case of the cut gear, the periphery of which has been changed when the metal is cold.

3th. Any alloy steel gear, the blank of which can be drop-forged, can be rolled. With some silieo-manganese steels which are practically impossible to machine, the blanks can have the teeth rolled and ground afterwards if desired; the hole being ground, there are two operations only—forging and grinding. 6th. As the gears are held at the periphery and the hole is bored afterwards 'on a chuck which chtic.ks from the pitch line of the teeth, the hole most he concentric with the pitch diameter, thus preventing a sprung arbor cutting an eccentric gear. The rolling process applies to bevel as well as spur gears, in which case the cost is decreased far more.

In roughing a bevel with this process, the sides of the teeth have the true curve, with an evenly added amount of finish allowance. This is in contrast to the ordinary roughing machine which cuts a straightside on the teeth. There is no question but that, with more development of this process, gears can be used in the lower-priced cars without any finishing cuts being required other than running the gears in properly.—Abridged from a. recent issue of " The Automobile," New York, U.S.A.