A New Heavy-duty Tipper

Page 50

If you've noticed an error in this article please click here to report it so we can fix it.

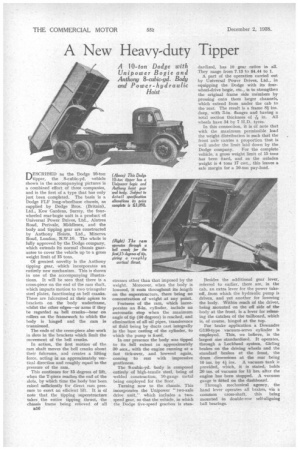

DESCRIBED as the Dodge 10-ton L./tipper, the 8-cubic-yd. vehicle shown in the accompanying pictures is a combined effort of three companies, and is the first of a type that has only just been completed. The basis is a Dodge FLF long-wheelbase chassis, as supplied by Dodge Bros. (Britain), Ltd., Kew Gardens, Surrey, the fourwheeled rear-bogie unit is a product of Universal Power Drives, Ltd., Aintree Road, Perivale, Middlesex, and the body and tipping gear are constructed by Anthony Hoists, Ltd., Minerva Road, London, N.W.10. The whole is fully approved by the Dodge company, which extends its normal chassis guarantee to cover the vehicle up to a gross weight limit of 15 tons.

Of greatest novelty is the Anthony tipping gear, which incorporates an entirely new mechanism. This is shown in one of the accompanying illustrations. It will be seen that there is a cross-piece on the end of the ram shaft, which imparts motion to two triangular steel plates, functioning as bell cranks. These are fulcrumed at their apices to brackets on the body underframe, whilst the other edges—or arms if they be regarded as bell cranks—bear on rollers on the framework to which the body is hinged and the ram is trunnioned.

The ends TA the cross-piece also work in slots in the brackets which limit the movement of the bell cranks.

In action, the first motion of the ram shaft moves the bell cranks about their fulcrums, and creates •a lifting force, acting in an approximately vertical direction ,and roughly equal to the pressure of the ram.

This continues for 15 degrees of lift, when the T-piece reaches the end of the slots, by which time the body has been raised sufficiently for direct ram pressure to exert an efficient lift. It is of note that the tipping superstructure takes the entire tipping thrust, the chassis frame being relieved of all 1116

stresses other than that imposed by the weight. Moreover, when the body is lowered, it rests throughout its length an the superstructure, there being no concentration of weight at any point.

Features of the ram, which incorporates an 8-in, cylinder, include an automatic stop when the maximum angle of tip (50 degrees) is reached, and elimination of all oil pipes, transference of fluid being by ducts cast integrally in the base casting of the cylinder, to which the pump is fixed.

In our presence the body was tipped to its full extent in approximately 30 secs., with the engine running at a fast tick-over, and lowered again, coming to rest with impressive gentleness.

The -cubic-yd. body is composed entirely of high-tensile steel, being of welded construction, 10-gauge metal being employed for the floor.

Turning now to the chassis. This incorporates the Unipower "two-axle drive unit," which includes a twospeed gear, so that the vehicle, in which the Dodge five-speed gearbox is stan dardized, has 10 gear ratios in all. They range from 7.13 to 84.44 to 1.

A part of the operation carried out by Universal Power Drives, Ltd., in equipping the Dodge with its fourwheel-drive bogie, etc., is to strengthen the original frame side members by pressing onto them larger channels, which extend from under the cab to the rear. The result is a frame 81 ins. deep, with 3-in, flanges and having a total section thickness of 176 in. All wheels have 34 by 7 H.D. tyres.

In this connection, it is of note that with the maximum permissible load the weight distribution is such that the front axle carries a proportion that is well under the limit laid down by the

Dodge company. For the complete vehicle, a gross weight limit of 15 tons has been fixed, and as the unladen weight is 4 tons 17 cwt., this leaves a safe margin for a 10-ton pay-load.

Besides the additional gear lever, referred to earlier, there are, in the cab, an extra lever for the power takeoff, from which the hydraulic pump is driven, and yet another for lowering the body. Within reach of the driver, being mounted on the off side of the body at the front, is a lever for releasing the catches of the tailboard, which is, of course, hinged at the top.

For brake application a Dewandre G110-type vacuum-servo cylinder is employed. This, we believe, is the largest size standardized. It operates, through a Lockheed system, Girling brakes on the driving wheels and the standard brakes at the front, the drum dimensions at the rear being 16 ins. by 41 ins. A vacuum tank is provided., which, it is stated, holds 20 ins, of vacuum for 14 hrs. after the engine has been stopped. A vacuum gauge is fitted on the dashboard.

Through mechanical agency, the hand lever operates all brakes, via a common cross-shaft, this being mounted in double-row self-aligning ball bearings.