• THE DAIMLER PROGRAMME FOR 1925.

Page 12

Page 13

If you've noticed an error in this article please click here to report it so we can fix it.

Two Editions of the Company's 3-ton Chassis now Available. Brief Technical Details of a Model which has Achieved much Success for Goods and Passenger Service.

FOR THE coming season the 3-ton chassis constructed by the Daimler Co„ Ltd.., of Coventry, will be available in two editions, type C.J. with an 11-ft. (1-in wheelbase, costing £595, and type C.K. with a 13-ft. wheelbase, costing £645. The design of these chassis is identical; with the exception that the O.K. model is fitted with a propeller

shaft some 2 ft. longer than that used on the other vehicle, thus allowing for the increased wheelbase.

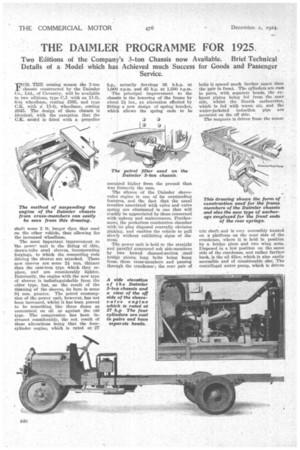

, The most important improvement to the powe'. unit is the fitting of thin, drawn-tube steel sleeves, incorporating forgings, to which the connecting rods driving the sleeves are attached. These new .sleeves are some 21 mm. thinner than the cast-iron type which they replace, and are considerably lighter. Externally, the engine with the new type of sleeves is indistinguishable from the older type, but, as the result of the thiThing of the sleeves, its bore is some 91 mm. greater. The petrol consumption of the power unit, however, has not been increased, whilst it has been proved to be something like three times as economical on oil as against the old type. The compression has been in-creased considerably, the net result of these alterations being that the fourcylinder engine, which is rated at 27 h.p., actually develops 36 b.h.p. at 1,000 r.p.m. and 45 h.p. at 1,500 r.p.m.

The principal improvement to the chassis is the lowering of the frame by about 21 ins., an alteration effected by fitting a new design of spring bracket, which allows the spring ends to be mounted higher from the ground than was formerly the case.

The silence of the Daimler sleevevalve engine is one of its outstanding features, and the fact that the usual troubles associated with valve and valve spring are eliminated is one that will readily be appreciated by those concerned with upkeep and maintenance. Furthermore, the pocketless combustion chamber with its plug disposed centrally obviates pinking, and enables the vehicle to pull slowly without exhibiting signs of distress.

The power unit is held to the straight and parallel armoured ash side-members by two bowed channel-section steel bridge pieces, long bolls being hung from these cross-members and passing through the crankcase ; the rear pair of bolts is spaced much farther apart than the pair in front. The cylinders are cast in pairs, with separate heads, the exhaust piping being led from the near side, whilst the Zenith carburetter, which is fed with warm air, and the water-jacketed induction pipe are mounted on the off side.

The magneto is driven from the eccen tric shaft and is very accessibly located on a platform on the near side of the crankcase, where it is held in position by a bridge piece and two wing nuts. Disposed in a low position on the same side of the crankcase, and rather farther hack, is the oil Eller, which is also easily accessible and of considerable size. The centrifugal water pump, which is driven from the front end of the magneto shaft through the medium of a fabric connection, is also positioned so as to be readily reached. • The lubrication system relies on a multi-plunger oil pump, which supplies oil to troughs interconnected with the throttle in such a way that, when the latter is opened and the load increased, they are raised in order to enable more oil to be scooped up by the connectingrod dippers and flung into the big-end bearings, the sleeves and their operating mechanism. The three crankshaft bearings are supplied with oil by a separate plunger of the pump, which draws its supply through a filter from the sump.

The engine power is taken through a fabric-lined eine clutch, equipped with a single volute spring and two flexible couplings, to the four-speed gearbox. Each end of the clutch shaft is splined o enable the end-on movement produced by declutching to be accommodated, whilst a dutch brake, in the form of a band which is brought into engage meat with a drum on the clutch shaft, is another feature of note.

The gearbox is formed by a single iron casting, which is attached at four points to two armoured wood cross-members. A large inspection door is fitted in the rectangular plate which forms the lid of the box, the removal of this plate and of the rear ends of the gearshaft bearing housings allowing the gearwheels and gearshafts to be assembled or withdrawn. The castellated gearshafts run on plain bearings, the ratios on the indirect speeds being as follow :—Third 1.46, second 2.09, first 4, and reverse 3.23 in conjunction with a worm ratio of 4 to 29 or 4 to 25., The final transmission relies on an open propeller shaft, each end of which is provided with a ball-'bearing mechanical joint entirely enclose() and rendered grease-tight by means of spring-loaded leather pads. These joints, like other parts of the chassis requiring lubrication, are provided with nipples for taking a grease gun.

The back axle incorporates a DaimlerLanchester high-efficiency worm gear, which is notable for its silence and exceptional durability. The gear is automatically lubricated by its own motion, and is contained partly in a cast-iron

bowl, the sides of which are extended outwards to form the axle casings, and terminate in flanges, to which the spring brackets are attached, and partly in the worm case proper, which seals the top of the bowl. The axle is Of the floating type, the differential being held by four vertically positioned bolts which project through the top side of the case, whilst the sleeves on each side are strengthened by steel tubes, the outer ends of which carry the wheels. The half-elliptic springs are mounted above the spring brackets, and are relied upon to take the torque.

The brakes are enclosed and located side by side, all four pairs of shoes being interchangeable. The brake-cam actuating rods are situated below the axle, and communicate with the adjustable rear ends of the horizontal controls by means of semi-circular levers. The controls are arranged side by side, the inner set operating the foot brakes and the outer pair the hand brake. The hand and foot cross brake controls are mounted respectively in front of and behind one of the principal cross-members of the frame, the layout being both robust and Ifccessible.

The front axle is also equipped with half-elliptic springs and east-steel wheels running on bronze hub bearing-3. Solid Dunlop tyres of 100 mm. dimensions for fitting to 771 roin. diameter rims are standardized, twin wheels, running on taper roller bearings, being fitted at the rear. The steering box, which houses a worm and wheel, is mounted on the offside member, the layout incorporating ball joints for the steering connections and an adjustable track rod. Both hand brake and gear controls are also mounted on the off side, while the fuel tank, of 201 gallons capacity, is situated under the driver's seat and is set athwart the frame. A screw-down needle valve is fitted in the tank, and a filter, which is incorporated in the fuel supply system, is mounted under the off-side member.

The framing is formed of ash beams sandwiched between flitch plates, which are bolted and riveted in position, the side members being linked by three steel and four armoured cross-members. Their forward extremities carry the built-up radiator, equipped with a guard rail (which also conies in useful as a support for the driver when cranking the engine and for towing, should this ever be necessary).

The principal dimensions of the C.J. chassis are as follow :—Wheelbase 11 ft. 6 ins., overall length 16 ft. 9 ins., platform space 13 ft. 4 ins., and turning circle 46 ft. Similar measurements for the C.K. chassis are as follow :—Wheelbase 13 ft. 6 ins., overall length 20 ft. 9 ins., platform space 17 ft. 4 ins., and turning circle 52 ft. 6 ins. In both cases the ground clearance is 9 ins.

We have, we believe, said enough to prove that these chassis are eminently practicable propositions and deserving of attention from potential buyers.