A SIX-WHEELED DOUBLE-DECKER BUS.

Page 9

Page 10

If you've noticed an error in this article please click here to report it so we can fix it.

A New American Vehicle, the Chassis of which Possesses Several Outstanding Features of Design, Notably in Connection with the System of Braking Employed.

IN the article entitled "The Growing Interest in Rigid Six-wheeleis," which appeared in our issue for November 180, we reviewed the whole field of progress and development in connection with multi-wheeled vehicles, and mention was made of a new type of double. deck bus of which a number is being put into service in Los Angeles. We are now in a position to amplify these details, which were necessarily meagre on account of the fact that our article was intended to serve as an analytical and comparative survey rather than as a eulogy of any one particular type of machine.

It is very obvious, from information which regularly reaches us from America, that the rigid six-wheeled vehicle is making considerable headway in the United States, and the appearance of a number of double-decker buses of this pattern on the streets of Los Angeles merely serves to emphasize the fact that the serviceability of such vehicles is being tested in all possible ways. First, it was goods vehicles, then saloon coaches and single-decker buses. and now doubledecker buses, so that it would seem that we are on the fringe of extensive developments, the ultimate effect of which may be to revolutionize existing forms of road transport. vehicle.

For the moment, the initiative in these experiments is being taken by American makers, but signs are not lacking to show that British and Continental manufacturers, after having exercised a period of caution, are awakening to the possibilities of the rigid six-wheeler and are following closely at their heels. Of most of these developments wehave already had something to say, and we shall continue to record further progress of the many efforts now being made "to spread the load and save the road" by the employment of vehicles with six, eight or more wheels.

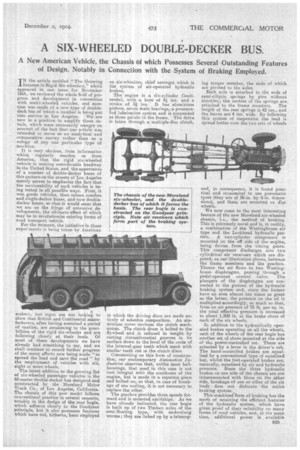

The latest addition to the growing list of six-wheeled passenger vehicles is the 60-seater double-decker bus designed and conStrueted by the Moreland Motor Truck Co., of Los Angeles, California. The chassis of this new model follows conventional practice in several respects, notably in the design of the rear bogie, which adheres closely to the Goodyear principle, but it also possesses features which have not, hitherto, been employee!

on six-wheelers, chief amongst which is the system of air-operated hydraulic brakes.

The engine is a six-cylinder Continental, with a bore of 41 ins, and a stroke of 5i ins: It has aluminium pistons, seven main bearings, a pressurefed lubrication system and is suspended at three points in the frame. The drive, is taken through a multiple-disc clutch, 3n which the driving discs are made entirely of asbestos composition. An aluminium cover encloses the clutch mechanism. The clutch drum is bolted to the flywheel and is reduced in weight by cutting circumferential grooves in its surface down to the level of the roots of the internal-gear teeth which mesh with similar teeth cut in the clutch acs.

Commenting on this form of construction, our contemporary Ala-emotive Industries observes that, unlike most bellhousings, that used in this. case is not cast integral with the crankcase of the engine, but is made in a separate piece and bolted on, so that, in case of breakage of one casting, it is not necessary to replace the other.

The gearbox provides three speeds forward and is mounted amidships. As we have already indicated, the rear bogie is built up of two Timken axles of the semi-floating type, with underslung worms; they are linked up by a telescop

ing torque member, the ends of which are pivoted to the axles. Each axle is attached to the ends of semi-elliptic springs by pins without shackles; the centres of the springs are attached to the frame members. The length of the rear springs is 42 ins., and the leaves are 4 ins. wide. By following this system of suspension the load is spread better over the two sets of wheels

and, in consequence' it is found practical and economical to use pneumatic tyres (they are of 36-in. by 8-in. dimensions), and these are mounted on d:se wheels.

We now come to the most interesting feature of the new Moreland six-wheeled chassis, Le., the method of braking. This is extremely novel and is, in reality, a combination of the Westinghouse air type and the Lockheed hydraulic pattern. A two-cylinder compressor is mounted on the off side of the engine, being driven from the timing gears. This compressor discharges into two cylindrical air receivers which are disposed, as our illustration shows, between the frame members and the gearbox. Thence the air flows to two Westinghouse diaphragms, passing through a pedal-operated control valve. The plungers of the diaphragms are connected to the pistons of the hydraulic braking system and, since the former have an area almost ten times as great as the latter, the pressure on the oil is multiplied accordingly, so much so that, from an air pressure of 75 lb. per sq. in. the total effective pressure is increased to about 1,200 lb. at the brake shoes of each of the six wheels.

In addition to the hydraulically operated brakes operating on all the wheels, each of the wheels of the rear bogie has another set of shoes mounted at the side of the power-controlled set. These are actuated by a lever in the driver's cab. The hand-controlled brakes are equalized by a conventional type of equalized bar, whilst the foot-operated brakes are, naturally, equalized by air and hydraulic pressure. Since the three hydraulic brakes on one side of the chassis are not, interconnected with those on the other side, breakage of one or other of the air leads does not dislocate the entire braking system.

This combined form of braking has the merit of retaining the efficient features of the hydraulic system, which have given proof of their reliability on many forms a road vehicles, and, at the same time, additional power is available

through the medium of air pressure for bringing about the rapid retardation of a heavy vehicle.

The other chassis features conform, more or less, to accepted ideas, but SOMB reference should be made to the lowloading 60-seater body which it carries. The entire body frame is built up of pressed-steel channel members, strengthened with cast-aluminium brackets, and it, is mounted on a bed built up of

angle-iron. The upper panels of the body are constructed of sheet aluminium, whilst those covering the lower portion are of Plymetal. As the roof is of i-in. Haskelite, it will be seen that little use is made of wood in the construction of the body, other than for the floorboards, lining panels and the truss-shaped slats which assist the roof channels to carry the load. The body proper does not overhang the chassis frame, which extends but a few inches beyond the rear wheel.

The upholstering of the seats in the interior saloon is carried out in leather, whilst on the 'tipper deck they are covered with rattan. A feature of the top deck is the swinging felt pad with which every seat is provided, and this can be used as a back-rest or as a seat, so that it is possible for each passenger to be provided with a dry, seat in rainy weather. In the absence of a cover this should assist in the use of the seats on the upper deck in doubtful weather.

Five of these six-wheelers are already in regular service in Los Angeles, where they appear to be giving satisfaction to the company owning them and to the travelling public