SCG's 'bolt-on' automatic for buses

Page 33

Page 34

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

by Martin Hayes

A PROLIFERATION of new transmission development aimed at bus operators has come on the market in the past year or two. From Britain, Leyland's G2 automatic and Ford's ESTA semi-automatic control system are two examples. And quite a number have come from Continental manufacturers.

The general impetus for this stream of technical advancement has been the growing difficulty in recruiting and retaining bus drivers. In many fleets which still have a mixture of manual transmission vehicles, there is a definite move against driving three-pedal buses.

Drivers, usually through unionmanagement committees, are indicating more frequently that if they are to be expected to drive in Britain's congested cities and collect fares at the same time they cannot be expected to cope with the Ad d it io na I task of making manual gear hanges.

Conversely and to the considerable innoyance of some bus manufacturers ind operators they are not happy about tccepting fully automatic transnissions. however. While many verating engineers have decided, albeit -eluctantly, that the only reliable thernative to manual transmission for ity work is a fully automatic gearbox.

Experience has shown that the more 'oolproof the control system for the ransmission, the less chance there is of he driver being able to abuse it. This has )een one of the criticisms of semi-autonatic transmissions, which when :oUpled with a rear engine, give endless cope for a driver to do serious damage o expensive mechanical units.

One development which has gone argely unheralded but which has a' ignifieant potential for relieving this ype of abuse is Self Changing Gears' :83 control system. This is designed as a • olt-on attachment for SCG's airiperated gearboxes and converts them rom semito fully-automatic rperation. Although the C83 first ppeared in 1968, it has only recently ,egun to be adapted in substantial numbers. There are now more than 400 buses fitted with the device and there are orders in the pipeline to equip another 300 or so.

The three cities where the majority of the units are in service are Glasgow, Leeds and Bristol. Leeds has had the longest experience with more than 2m miles of C83-controlled gearbox operation. In that time there has been only one gearbox failure and that was thought to be a "rogue" box. There have been no fluid flywheel failures on the undertaking's Leyland Atlanteans. Problems with the semi-automatic version of the SCG bus have often been caused by drivers starting from rest in second instead of first gear. The automatic control ensures that starts are made in first gear.

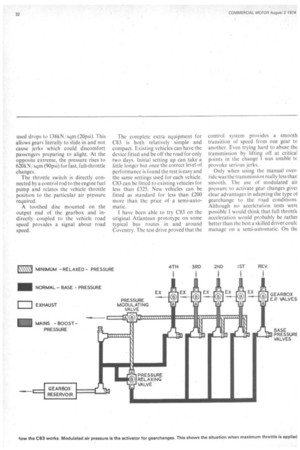

The C83 system comprises five basic components. There is a selector switch in the form of a conventional-looking gear selector gate. In most applications it has a reverse. 1, 2, 3, and automatic position. The numbered positions give control of all gears. Some or all of these override positions can be omitted if required..

Signals from the selector switch together with those from a throttle switch and a gearbox probe are sent to a control panel. This translates them to a modulating valve block which in turn activates the relevant gearbox brakeband operating cylinder at a correct, predetermined air pressure. Settings in the control panel can be quickly and easily amended to take account of different operational conditions. Each transmission is set up to take account of different terrain in, say, Glasgow and Bristol. The air pressure is varied depencient on engine torque and throttle position.

During normal changes an air. pressure of 414kNisqm (60psi) is used. During deceleration to rest the pressure used drops to 138kN / sqm (20psi). This allows gears literally to slide in and not cause jerks which could discomfort passengers preparing to alight. At the opposite extreme, the pressure rises to 620kN/ sqm (90psi) for fast, full-throttle changes.

The throttle switch is directly connected by a control rod to the engine fuel pump and relates the vehicle throttle position to the particular air pressure required.

• A toothed disc mounted on the output end of the gearbox and indirectly coupled to the vehicle road speed provides a signal about road speed. The complete extra equipment for C83 is both relatively simple and compact. Existing vehicles can have the device fitted and be off the road for only two days. Initial setting up can take a little longer but once the correct level of, performance is found the rest is easy and the same settings used for each vehicle. C83 can be fitted to existing vehicles for less than £325. New vehicles can be fitted as standard for less than £200 more than the price of a semi-automatic.

I have been able to try C83 on the original Atlantean prototype on some typical bus routes in and around Coventry. The test drive proved that the control system provides a smooth transition of speed from one gear to another. Even trying hard to abuse the transmission by lifting off at critical points in the change I was unable tc provoke serious jerks.

Only when using the manual override was.the transmission really less than smooth. The use of modulated an pressure to activate gear changes gives clear advantages in adapting the type oi gearchange to the road conditions. Although no acceleration tests were possible I would think that full throttle acceleration would probably be rathet better than the best a skilled driver coule manage on a semi-automatic. On the vehicle I tried there was a built-in kickdown feature, but this is optional.

Latest developments on the C83 have been initiated during work on Ailsa's new double decker. This has a five-speed transmission, with the top four gears being changed automatically and first being engaged manually for starts from rest. Work has gone on during Ailsa's intensive development programme to reduce transmission noise and engine smoke at the same time as improving fuel consumption. Relatively minor adjustments to the SCG control system have paid good dividends here. To improve efficiency a transmission oil cooler has been fitted. The SCG sales team sees the C83 as a useful progression for operators treading the path from manual boxes, through semi-automatics to fully automatic transmission. Already, operators who have had experience with C83 are moving on to the more sophisticated — and more expensive — G2 unit which is integrated with Leyland's close ratio gearboxes.

Union opposition

The only real opposition to C83, has, perhaps not surprisingly, come from the unions. 1 he old argument that automatic transmission reduces the responsibility of a skilled driver has been given an airing in some places but SCG policy is now for early consultation. It is felt that if drivers can be convinced that the control system is likely to improve the reliability of vehicles they will accept it all the quicker.

C83 seems a commendably simple and therefore cheap and hopefully reliable development in the field of easing the driver's task. If it can reduce vehicle abuse too, as seems likely, it should be a worthwhile investment. Certainly, until operators have reached the stage of specifying fully integrated automatics on new vehicles this bolt-on extra could be a useful introduction to automatics.