Bodyfra me kit

Page 34

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

A steel-jointed van bodyframe which it is claimed can be erected in 2 hours by unskilled labour is now marketed in kit form by W. Jones (Manchester) Ltd.

This kit is likely to prove popular when licence restrictions are lifted on vehicles below 30cw1 because a 550 Cu. ft. capacity body can be constructed on a 25cwt petrol chassis. such as the Transit, within this unladen weight.

Known as the Callpri building method, the 1in. square steel tubes, produced by Dexion, are supplied cut to length, together with die-cast alloy joints, covering six possible right-angled intersections, and moulded creepresistant plastics inserts which effect a strong joint.

Only the chassis and body dimensions required need to be furnished since Jones produces the body layout and supplies working drawings with the kit. The inserts, designed to create two pressure points at each join, are placed inside the tube. When the tube lengths required for one side of the frame have been laid out on the ground, the joints are inserted and hammered home.

Any flexing or strain in transit is taken by the plastics joint, which is as rigid as a welded joint but not as susceptible to wear and tear as a bolted section. The method is repeated for the other side, the bulkhead, the back frame and the roof, and then all parts are assembled, using the roof as a base and then dropped onto the chassis.

Shelving for mobile shops can also be incorporated. Usual cladding methods are then employed.

As 80 to 90 hours work by skilled carpenters is required to construct a conventional timber frame, this kit should appeal to the small bodybuilder for the one-off job because of the large reduction in man-hours afforded, as the planning, designing and cutting stages are all eliminated.

Produced by: W. Jones (Manchester) Ltd.. Rutland Street Garages, Swinton, Manchester. Example of cost: a kit for a standard body with 8ft panelling and 730 Cu. ft. capacity would be £36 14s 3d.

Vehicle washer

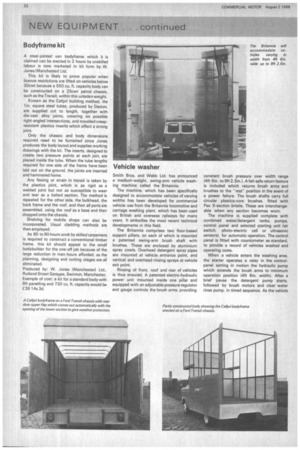

Smith Bros. and Webb Ltd. has announced a medium-weight, swing-arm vehicle washing machine called the Britannia.

The machine, which has been specifically designed to accommodate vehicles of varying widths has been developed for commercial vehicle use from the Britannia locomotive and carriage washing plant, which has been used on British and overseas railways for many years. It embodies the most recent technical developments in this field.

The Britannia comprises two floor-based support pillars, on each of which is mounted a patented swing-arm brush shaft with brushes. These are enclosed by aluminium spray cowls. Overhead detergent spray pipes are mounted at vehicle entrance point, and vertical and overhead rinsing sprays at vehicle exit point.

Rinsing of front, roof and rear of vehicles is thus ensured. A patented electro-hydraulic power unit mounted inside one pillar and equipped with an adjustable pressure regulator and gauge controls the brush arms. providing constant brush pressure over width range (4ft 6in. to 8ft 2.5in.). A fail-safe return feature is included which returns brush arms and brushes to the "rest" position in the event of a power failure. The brush shafts carry full circular plastics-core brushes, fitted with Pex X-section bristle. These are interchangeable when any section becomes worn.

The machine is supplied complete with combined water/detergent tanks, pumps, control panel and selected starting unit (air switch, photo-electric cell or ultrasonic sensors), for automatic operation. The control panel is fitted with countometer as standard, to provide a record of vehicles washed and operating costs.

When a vehicle enters the washing area, the starter operates a relay in the controlpanel setting in motion the hydraulic pump which extends the brush arms to minimum operation position (4ft 6in. width). After a brief pause the detergent pump starts, followed by brush motors and clear water rinse pump, in timed sequence. As the vehicle enters the brushes automatically adjust to the vehicle width maintaining a hydraulically controlled brush pressure. The brush arms automatically retract into the spray cowls on conclusion of pre-timed cycle.

The maximum installation width is only 14ft 9in, and the brush pillars have been so designed for convenient installation inside the average gate entrance. The machine is available in three models: SA1 suitable for cleaning vehicles up to lift high: SA2 suitable for cleaning vehicles up to 13ft high: and SA3 suitable for cleaning vehicles up to 15ft high. Operating costs, including depreciation, average a fraction over 2d per wash and installation of the completely automatic unit is carried out by the manufacturer's engineers.

The machine will be marketed in association with Equipment and Engineering Co. Ltd., London, EC2.

Made by: Smith Bros. and Webb Ltd., Sparkbrook, Birmingham.

Cleaning wax

A car cleaning wax, developed on a new formula to resist detergents, is announced by Simoniz Ltd., 125 High Holborn, London, WC1, called GT Wax. The product is said to be the result of over two years' research to introduce a cleaning wax that measures up to the most stringent demands of the modern vehicle-care market.

GT Wax is an emulsion polish incorporating a new wax ingredient which is the basis of a Simoniz patent. It contains an emulsifier unlike any used in a polish system to date. This ingredient blends in chemically with paint finishes, and when it is air-cured it changes chemically and becomes water and detergent resistant.

One of the principal advantages claimed for the polish is that it protects and shines even after many washings, resisting the most powerful detergent soaps encountered in the variety of car-cleaning techniques employed by automatic car washes and garages. etc.

GT Wax is being marketed in a 902 round seamless paste-type container and is available from all leading garages and accessory shops. Made by: Simoniz Ltd.. 125 High Holborn, WC1.

Price: 12s 6d per 9oz tin.

Appointments GKN Screws and Fasteners Ltd. has announced the following changes to the territories covered by salesmen: K. Merryfield from Heath Street division to Fredk. Mountford (Birmingham) for the Midlands; D. J. Hutton, Fredk. Mountford, from Midlands to South West England: B. Rothstein joins Fredk. Mountford, to cover south of Thames: D. 0. Wills from Heath Street division to King's Norton division as sales manager London--E. Counties. And from October 1 A. Ouchterlonie, Heath Street division, moves from Midlands to South West England.

Aven Tools Ltd. (formerly Hack Saws Ltd.) of Maltby. Yorics. has appointed R. S. Roberts as retail sales representative responsible for South and South West England. Mr. Roberts will promote and sell the range of Aven hand-tools to wholesalers and be responsible for organizing and coordinating the field force of merchandising representatives in this area. He joins I. M. Buchanan who covers the northern part of England.