SH WAY

Page 47

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

By John F. Moon A.M.1.R.T.E.

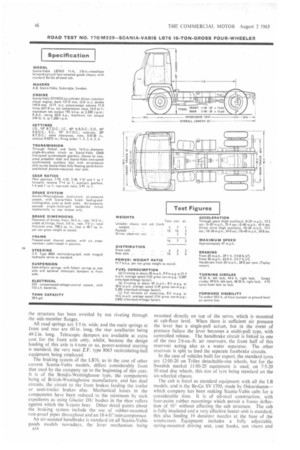

diesel engine used in the normal-control L76 models, whilst optional is a turbo-charged version, the net power output of which, at 222 b.h.p., is 30 bhp. higher than that of the normally aspirated unit, indicating a modest degree of blowing.

Mechanical actuation is employed for the Fichtel und Sachs 16-5-in, clutch, and operating effort is reduced by an assist spring which successfully makes the clutch light to release but had the tendency on the vehicle tested to make re-engagement somewhat harsh and unpredictable. Unitmounted with the engine-clutch assembly is a Scania-Vabis G660 five-speed gearbox, which has synchromesh on the upper four ratios and pressure lubrication. The gearchange lever is of the remote type, mounted on the side of the cylinder block, and the lever travel is comfortably small when compared with the travel of the direct-change version used in normal-control chassis of this make.

As with most Scania-Vabis heavy vehicles, a two-speed synchromesh auxiliary gearbox is offered with the LB models, this being separately mounted and adding just over 2-25 cwt. to the chassis weight. Whereas on normal-control models this box is controlled by a separate lever with mechanical linkage, in the LB the box is air operated and controlled by a neat trigger attached to the main gearchange lever, so that changes can be made in the same way as with a two-speed axle a most convenient arrangement.

The standard rear axle is a single-reduction assembly with spiral-bevel gearing. This incorporates an air-operated differential lock and has a pressed-steel housing, and the available ratios are 4.67, 5-13 and $-71 to 1, giving approximate maximum speeds at 2,200 engine r.p.m. and on 12-00-20 tyres of 59, 54 and 48 m.p.h. respectively. The test vehicle, which had the auxiliary gearbox, was equipped with the optional double-reduction axle, the primary gearing of which is spiral-bevel, whilst the secondary gears are single helical. This axle, which also incorporates a differential lock as standard, weighs 2 cwt. more than the single-reduction axle and the choice of ratios is 4-93 or 5.91, giving respective maximum speeds of 56 and 47 m.p.h. At the maximum permissible gross train weight the low-ratio double-reduction axle gives a bottom-gear gradient ability of 1 in 6-5 with direct auxiliary and 1 in 4.5 using the low auxiliary ratio. At the recommended solo rating of 16-25 tons these figures become 1 in 2.85 and 1 in 1.9 respectively. One could hardly ask for an improvement on that sort of gradient ability! The primary object of the double-reduction axle is, of course, to permit operation at higher gross train weights, and with this unit the Scania-Vabis figure on good roads is 39-5 tons, compared with 34.25 tons for the standard axle.

fn all cases the chassis frame is an impressive assembly. The side members have 0.3-in.-thick main pressings, with a depth of 9-9 in. and 3.3-in, flanges, and inside these channels are fitted 9.3-in. by 3.0-in. by 0-2-in. flitch channels, which extend from just behind the front axle to behind the rear axle. The channel-section cross-members are riveted in place, like the springhanger brackets, and weakening of

the structure has been avoided by not riveting through the side-member flanges.

All road springs are 3.5 in. wide, and the main springs at front and rear arc 60 in. long, the rear auxiliaries being 49.2 in. long. Telescopic dampers are available at extra cost for the front axle only, whilst, because the design loading of this axle is 6 tons or so, power-assisted steering is standard, the very neat Z.F. type 8065 recirculating-ball equipment being employed.

The braking system of the LB76, as in the case of other current Scania-Vabis models, differs considerably from that used by the company up to the beginning of this year. It is of the Bendix-Westinghouse type, the components being of British-Westinghouse manufacture, and has dual circuits, the circuit to the front brakes feeding the trailer or semi-trailer brakes also. Mechanical losses in the components have been reduced to the minimum by such expedients as using Glacier DU bushes in the shoe rollers against which the S-cams bear. Other detail points about the braking system include the use of rubber-mounted rust-proof pipes throughout and an 18.4-ft3imin compressor.

An air-assisted handbrake is standard on all Scania-Vabis goods models nowadays, the lever mechanism being nt4 mounted directly on top of the servo, which is mounted at cab-floor level. When there is sufficient air pressure the lever has a single-pull action, but in the event of pressure failure the lever becomes a multi-pull type, with controlled release. The handbrake circuit is linked to one of the two 2-6-cu.-ft. air reservoirs, the front half of this reservoir acting also as a water separator. The other reservoir is split to feed the separate footbrake circuits.

In the case of vehicles built for export, the standard tyres are 12-00-20 on Trilex detachable-rim wheels, but for the Swedish market 11-00-20 equipment is used, on 7.5-20 1O-stud disc wheels, this size of tyre being standard on the six-wheeled chassis.

the cab is listed as standard equipment with all the LB models, and is the Be-Ge SV 1700, made by Oskarshamnwhich company has been making Scania-Vabis cabs for a considerable time. it is of all-steel construction, with four-point rubber mountings which permit a frame deflection of 10° without affecting the cab structure. The cab is fully insulated and a very effective heater unit is standard, this also feeding 19 demister noLzles at the base of the windscreen. , Equipment includes a fully adjustable, spring-mounted driving seat, coat hooks, sun visors and

two interior lamps, whilst a sleeper version (type SV 2100) with either one or two bunks is available, this increasing the cab length by 15-75 in.

The short-wheelbase LB76 made available for test had a chassis-cab kerb weight of 5 tons 7-25 cwt., and iron weights totalling 10 tons 16.75 cwt. had been securely mounted to the chassis so that the total weight, with two people aboard, was 16 tons 7.5 cwt. All the tests were carried out in the Sodertalje area, the normalspeed fuel-consumption runs being made over a narrow, undulating out-and-return circuit of 16-6 miles between Ostertalje and Rosenhill. In view of the high average speeds maintained, the consumption rates recorded are not too bad, but had the test vehicle been fitted with the optional high-ratio axle the m.p.g. figures would probably have been some 10 per cent better.

Despite its comparatively low maximum speed of approximately 47 m.p.h., the LB76 returned an average speed of 43-6 m.p.h. on an 8.95-mite full-throttle test along the Stockholm motorway between Seidertalje and Fittja, whilst the consumption rate was quite reasonable at 8.2 m.p.g. Again, had the axle ratio been higher, better average-speed and consumption-rate figures would have been obtained.

The advantage of the low-ratio axle was shown when making the acceleration and hill-climbing tests, the acceleration runs being made with the high ratio of the auxiliary box engaged, and the figure between a standstill and 30 m.p.h. being 1.2 seconds better than that achieved nearly four years ago with a Scania-Vabis L75 equipped with a 165-b.h.p. engine and a slightly higher axle ratio, but running over a ton lighter. The direct-drive acceleration performance was good also, and there was no engine or transmissirm roughness when pulling away from 10 m.p.h.

A non-stop hill-climb was made up Tvetabacken Hill, Sodertalje, which is 0.5-mile long and has an average gradient of nearly 1 in 9. The ascent, which was made in an ambient temperature of 21°C. (70°F.), took only 2 min. 11 sec., and the lowest ratio-combination employed was third-high, this being engaged for 1 mm. 5 sec., during which period the speed fell momentarily to 12.5 m.p.h. There was no exhaust smoking at all, and the temperature of the coolant in the radiator header tank rose from its normal value of 73°C. (163-5` F.) to 76°C. (169F.), indicating ample cooling despite the absence of pressurization.

Stop-and-restart tests were made on Sankta Ragnhildsgatan, this slope, which is in the centre of Sodertalje, being of 1 in 5.8 severity. Third-low was used for the get-away while facing up the hill, and reverse-high when facing in the opposite direction, and on each occasion the handbrake held the vehicle with the greatest of ease. Again there was no exhaust smoking, but the clutch fierceness made it difficult to move away smoothly.

While on Tvetabacken, fade resistance had been checked by coasting down the hill in neutral, using the footbrake to keep the speed down to 20 m.p.h. The descent took 1-25 minutes, and a simulated crash stop at the bottom of the hill produced a Tapley-meter figure of 66 per cent, with the rear wheels locking for 10 ft. The meter figure compares very well with the average maximum deceleration obtained earlier when the drums were cold, under which conditions 79 per cent was obtained, and it is obvious that the generous frictional area of this chassis gives good anti-fade characteristics.

The normal braking tests were spoilt by excessive wheel locking, both the fronts and rears sliding from each of the test speeds. Oscillogram traces revealed a system delay of 0.4 sec., which couldn't have helped either, and the figures measured do not compare well with good British maximum-capacity four-wheelers, even allowing for the appreciable difference in weight. Handbrake efficiency was high, the average Tapley-meter reading being 38 per cent, obtained with the rear wheels locked for 30 ft.

Taken generally, the LB76 is a pleasant enough vehicle to drive, though British drivers would take some 'time to get accustomed to the lightness of the steering which, however, is apparently what Swedish drivers demand. The engine pulls extremely well in a high gear, as might be expected with such a high power-to-weight ratio, and the noise level in the cab is reasonable, being about the same as that in a good British heavy. The gearchange, which was stiff when I drove the vehicle because the chassis had covered less than 150 miles, showed-signs of being satisfactory, whilst the auxiliary box was very easy to use.

In view of the comparatively short wheelbase the suspension was good, although the front springs, working in conjunction with the optional dampers, tended to give a slightly harsh ride at times. The brakes behaved well under normal applications, and there was a comforting amount of feel in the pedal.

The cab, although a bit cramped, offers good driving conditions for long-distance work and the seats are extremely comfortable. The range of vision is good, although not quite up to the best British standards, and for some reason or other the windscreen-wiper layout is such as to leave a large unwiped V in the centre of the screen. The finish is of a high standard, but stowage space is rather sparse, the reason for this, I discovered later, being that Swedish operators prefer to install racks, nets and so forth to suit their own needs. A bad detail point is that the heater-fan motor is fully exposed and is positioned ahead of the passenger seat, so that an occupant of this seat is liable to rest at least one of his feet on the motor housing.

Engine accessibility is fair with the top cowl panel hinged back, and with the two side panels removed (six screws each) access then becomes good. A novel point is that, with the radiator grille removed, the radiator block can be swung outwards very simply, being secured by one single snap fastener, and with the radiator out of the way the whole front of the engine can be reached quite easily. This layout has been seen on Scania-Vabis vehicles before, namely, those forward-control conversions of the old L75 model effected in Holland by the Dutch agents, Adr. Beers N.V. So far as the rest of the chassis is concerned, maintenance of this is comparable with the maintenance of any other European heavy vehicle, except that there is a fair chance that less of it will be required!

In Sweden the LB7635 chassis-cab, as tested, sells for 58,500 Sw. Krona. which is equivalent to approximately £4,000 sterling. In view of the quality of the vehicle this figure is by no means extortionate, especially as the machine has been designed with operations at up to 40 tons gross train weight in mind, at which figure its performance would undoubtedly show up better than when used solo.