British Engines in Canada

Page 56

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

Canadian-Car Oil-engined Buses Now Fitted with A.E.C. Engines as Standard and Leyland 0.680. Engine Used in New Canada

Tractor Outfits

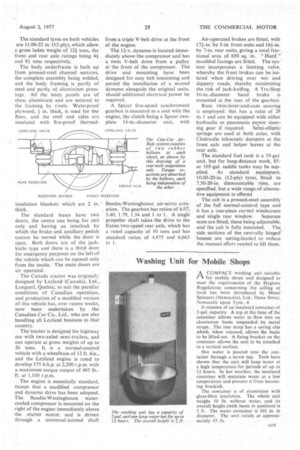

TWO well-known British power units now form an essential part of the road-vehicle production of the Canadian Car Co., Ltd. These units are the A.E.C. 11.3-litre six-cylindered horizontal oil engine, employed in Canadian-Car buses and coaches, and the Leyland 0.680 11.1-litre six-cylindered oil engine, which powers the new Canada road tractor.

Two A.E.C.-powered buses arc produced by the Canadian Car Co., at their Fort William, Ontario, factory. Both are underfloor-engirted integral vehicles, the larger bus, a 45-seater, having an overall length . of 39 ft. 10+ in. and an unladen weight of 81 tons. Theo other bus has 37 seats, is 35 ft. 5-1 in. long and has a .kerb weight of just over 8+ tons.

In both vehicles the A.E.C. engine, which is mounted midway between the axles, is rated to develop 152 bh,p. at 1,800 r.p.m. (the engine governor being set to allow a speed of 1,975 r.p.m. with no load applied) whilst the maximum torque rating is 487 lb.-ft. at 1,300 r.p.m.

Three-point rubber mounting is employed, with two sandwich-type rubber units at the flywheel housing and one tubular trunnion-mounting at the front of the engine. A 75-gal

fuel tank is fitted. N, Me", The vertical-flow-type radiator is mounted just forward of the engine and has a duct to prevent entry of water and dirt which might be thrown up from the road. A Kysor thermostatically controlled radiator shutter i. standard equipment, and under'shields are fitted between the radiator and the engine. The total capacity of the cooling system, including the body heaters, is 121 gal., and a 211-in.-diameter, six-bladed fully shrouded fan is used.

Hydraulic Torque Converter A Spicer-type 918 hydraulic torque converter is unit-mounted with the engine. This cuts into direct drive at 21 m.p.h., and gives a gradient ability of I in 5.5 with a rear-axle ratio of 6.143 to 1, which is the standard ratio for both buses. A Timken bypoidbevel fully floating axle is employed. . On both buses Can-Car air suspension is offered as an alternative to semi-elliptic springs, this having been introduced last April, and therefore being the first production form of air suspension to be applied outside the United States.

The Can-Car Air-Ride system consists of eight rubber bellows, four per axle, working in conjunction with telescopic dampers. The bellows are bolted to the bus underframe and to longitudinal square-section tubes which are attached to the axles. These tubes act as air reservoirs, are about 5 ft. long and are divided centrally so that each bellows forms a self-contained unit. In this way the provision of links to resist acceleration or braking torque is unnecessary, and the axles are located 'solely by means of radius rods, with a transverse Panhard rod at each unit to give lateral stability.

Rubber bumpers are incorporated in each spring to give protection against bottoming and failure of the air system, and rubber bushes are used in all linkages, with the result that no lubrication is necessary.

There are two levelling valves per axle, and these automatically control the flow of air in and out of the suspension units, according to the loading of each wheel, and thus the body of the bus remains level irrespective of road camber or passenger distribution.

As has already been found in the U.S.A., one of the main advantages of air suspension, other than the improved ride given to the passengers, is the greatly increased suspenision life and the reduced wear and tear on body and running components.

Gemmer worm-and-roller steering is employed, and on the larger bus Vickers hydraulic power assistance is standard equipment. Both vehicles have air brakes, 161-in. by 5-in, units being common to the front axles whilst the heavier vehicle has .16+-in. by 8-in, rear brakes, as opposed to the 16+-in, by 7-in, rear brakes of the 37-seater. A 12-in. by 5-in. internalexpanding drum brake, mounted at the back of the torque converter, is actuated by the hand brake. The standard tyres on both vehicles are 11.00-22 in..(12-ply), which allow, a grow laden weight of 12:4 tons, the front and rear axle -ratings being 44 and 81tons respectively.

The body underframe is built up from pressed-steel channel sections, the complete assembly .being waded, and the body framing is partly of steel and partly of aluminium pressings. All the body panels are of sheet aluminium and are secured to the framing by rivets. Waterproof plywood,:I in. thick, is used for the floor, and the roof and sides are insulated with fire-proof thermal insulation blankets which are 2 in. thick.

The standard buses have two doors, the centre one being for exit only and having an interlock by which the brake and auxiliary pedals cannot be moved while the door is open. Both doors are of the jackknife type and there is a third door for emergency purposes on the left of the vehicle which can be opened only frcim the inside. The main doors are air operated.

The Canada tractor was originally designed by Leyland(Canada), Ltd., Longueil, Quebec, to suit the peculiar conditions of Canadian operation, and production of a modified version of this vehicle has, over recent weeks, now been undertaken by the Canadian Car Co., Ltd., who are also handling all Leyland business in that country.

The tractor is designed for highway use with two-axled semi-trailers, and can operate at gross weights of up to 26 tons. It is a normal-control vehicle with a wheelbase of 12 ft. Gin., and the Leyland engine is rated to develop 175 b.h.p. at 2,200 r.p.m. with a maximum torque output of 495 lb.ft. at 1,100 r.p.m.

The engine is essentially standard, except that a modified compressor and dynamo drive has been adopted. The Bendix-Westinghouse watercooled compressor is mounted on the right of the, engine immediately above the starter motor, and is driven through a universal-jointed shaft from a triple V-belt drive at the front of the engine.

The 12-v. dynamo is located immediately above the compressor and has a _twin V-belt drive from a pulley at the front of the compressor. The drive and mounting have been designed for easy belt tensioning and permit the installation of a second dynamo alongside the original units, should additional electrical power be required.

A Spicer five-speed synchromesh • gearbox is mounted as a unit with the engine, the clutch being a Spicer. twoplate 14-in.-diameter unit, with

Bendix-Westinghouse air-servo actuation. The-gearbox has.ratios of 6.07, 3.40, 1.79, 1.34 and 1 to 1. A single propeller shaft takes the drive to the Eaton two-speed-rear axle, which has a rated capacity of 10 tons and has standard ratios of 4,875 and 6,663 to 1.

Air-operated brakes are fitted, with 171-in, by front units and 161-in. by 7-in, rear units, giving a total frictional area of 650 sq. in. " Hard " moulded facings are fitted. The system incorporates a limiting valve, whereby the front brakes can be. isolated when driving over wet and slippery roads, thereby minimizing the risk of jack-knifing. A Tru-Stop 16-in.-diameter hand brake is mounted at the rear, of the gearbox.

Ross twin-lever-and-cant steering is employed: this has a ratio of 28 to I and can be equipped with either hydraulic or pneumatic power steering gear if required. Semi-elliptic springs are used at both axles, with Cledraulie telescopic dampers at the front axle and helper leaves at the rear axle.

The standard fuel tank is a 35-gal. unit, but for long-distance work, 85or 105-gal. saddle tanks may be supplied. As standard equipTent, 10.00-20-in. (12-ply) tyres, fitted to 7.50-20-in. dismountable rims, are specified, but a wide range of alternative equipment is offered, The cab is a pressed-steel assembly of .the full normal-control type and it has a one-piece curved windscreen and single rear window. Separate seats are fitted, these being adjustable, and the cab is fully insulated. The side sections of the centrally hinged " bonnet are spring-loaded to reduce the manual effort needed to lift them.