Hopper Vehicle Feeds Furnaces

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

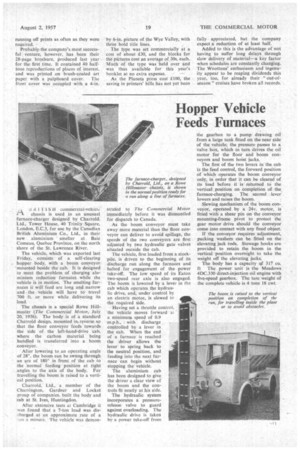

I 11SH commercial-vehicle /-1 chassis is used in an unusual furnace-charger designed by Charrold, Ltd., Tower House, 40 Trinity Square, London, E.C.3, for use by the Canadian British Aluminium Co., Ltd., in their new aluminium smelter at Baie Comeau, Quebec Province, on the north shore of the St. Lawrence River.

The vehicle, which was exported last Friday, consists of a self-clearing hopper body, with a boom conveyor .mounted beside the cab. It is designed to meet the problem of charging aluminium reduction furnaces while the vehicle is in motion. The smelting furnaces it will feed are long and narrow

• and the vehicle will have to travel 700 ft. or more while delivering its load.

The chassis is a special Rowe Hillmaster (The Commercial Motor, July 20, 1956). The body is of a standard Charrold design, mounted in, reverse so .that the door conveyor feeds towards the side of the left-hand-drive cab, where the carbon material being handled is transferred into a boom conveyor.

After lowering to an operating angle of 28°, the boom can be swung through an arc of 180' in front of the cab to the normal feeding position at right angles to the axis of the body. For travelling the boom is raised to a vertical position.

Charrold. Ltd., a member of the Charrington, Gardner and Locket group of companies, built the body and cab at St. Ives, Huntingdon.

After extensive tests at Cambridge it was found that a 7-ton load was discharged at an approximate rate of a on a minute. The vehicle was demon

strated to The Commercial Motor immediately before it was dismantled for dispatch to Canada.

As the boom conveyor must take away More material than the floor conveyor can deliver to avoid spillage, the speeds of the two conveyors are first adjusted by two hydraulic gate valves situated outside the cab.

The vehicle, first loaded from a stockpile, is driven to the beginning of its discharge run along the furnaces and halted for engagement of the power take-off. The low speed of its Eaton two-speed rear axle is also engaged. The boom is lowered by a lever in the cab which operates the hydraulic drive, and, under control by an electric motor, is slewed to the required side.

Having set a throttle control, the Vehicle moves forward at a minimum speed of 0.9 m.p.h., • with discharge controlled by a lever in the cab. When the end of a furnace is reached the driver allows the lever to spring back to the neutral position, and feeding into the next furnace can begin without

stopping the vehicle. • The aluminium cab has been designed to give. the driver a clear view of the boom and the controls fit neatly at his side.

The hydraulic system incorporates a pressurerelease valve to guard against overloading. The hydraulic drive is taken by a power take-off from

the gearbox to a pump drawing oil from a large tank fitted on the near side of the vehicle; the pressure passes to a valve box, which in turn drives the oil motor for the floor and boom conveyors and boom hoist jacks.

The first of the two levers in-the cab 13 the feed control, the forward position of which operates the boom conveyor only, in order that it can be cleared of its load before it is returned to the vertical position on completion of the furnace-charging. The second lever lowers and raises the boom.

SIewing mechanism of the boom conveyor, operated by a 24v. motor, is fitted with a shear pin on the conveyor mounting-frame pivot to protect the gear motor drive should the conveyor come into contact with any fixed object.

If the conveyor requires adjustment, packing washers can be fitted on the elevating jack rods. Stowage hooks are provided to retain the boom in the vertical position overnight to take the weight off the elevating jacks.

The body has a capacity of 317 Cu. ft. The power unit is the Meadows 4DC.330 direct-injection oil engine with five-speed gearbox. The tare weight of the complete vehicle is 4 tons 18 cwt.