Permutation

Page 81

Page 82

Page 84

Page 85

Page 86

Page 90

If you've noticed an error in this article please click here to report it so we can fix it.

--the theme

for New Fords WITH THE INTRODUCTION OF THE NEW D RANGE, FORD TAKES A FURTHER STEP FORWARD IN MEETING ALL REQUIREMENTS.

By A. J. P.Wilding,AMINIech E, MIRTE INCREASINGLY in the past few years The Ford Motor Co. Ltd. has extended the range of optional equipment available on its goods models so that the needs of operators could be more accurately met. At last year's Commercial Show the company's Special Vehicle Orders department was highlighted to show that as well as a wide range of variations in standard moclels, vehicles tailormade to particular requirements could be obtained.

With the introduction of the D range this week, Ford goes a step forward in meeting all requirements from a basic range—if it can be called a basic range, because although there are only eight model designations, there is considerable interchangeability possible between the units fitted in them. This means that although one model can have a set of running units giving it a. certain weight rating, alternatives can be incorporated to increase the figure. There are also van-body, tipper, dumper and tractive-unit versions of some models and 6 x 2 and 6 x 4 variations.

With versatility as the main theme of the Ford D range, the various models are built up as though using a boy's construction kit. Normal load-carrying vehicles of from 2to 8-ton capacity, tipper and dumper models for 7to 8-ton loads and tractive units for use at gross train weights of between 12.5 and 18-75 tons are listed. There is a wide choice of wheelbase. engine, gearbox, axle and braking system options, but standard on all models is a tilt cab. All have a forward-control layout and the D range replaces completely the -former Thames Trader cab-over-engine designs which have been in production

since 1957. '

With the introduction of the new range the name Thames

is dropped completely by Ford, all goods and p.s.v. models now being called simply Ford; at the same time, there have been changes to normal-control models—now called the Ford K series—with a new 6-tonner, two new tippers and the incorporation of a number of features from the D range. The Clearway vans are redesignated Ford M (Clearway), as explained in more detail on page 45.

Although replacing the forward-control Traders, the D range uses very few components from the old models, being completely redesigned from front to rear. Five engines offered include three diesels based on previous units (but having increased power and capacity) and two petrol engines which are from Ford of America, where they are used in goods chassis as well as in American Ford cars. Three gearboxes are used in the range and there are six types of rear axle, four braking systems and a wide variety of suspension and tyre options.

Study of the accompanying table showing brief specifications of four-wheelers and tractivz 'mils will give a good idea of the vat-jetv of running units available on each of the basic types. One point is important here: on the D series Ford 1.1:i; abandoned the oractice of de,,ienating models by load ratingThis means that the model numbers give only an indication of the load capacity. In some cases there is a definite connection between the number and load; in others, the load capacity can be above or below the nominal rating, depending on the optional units specified; whilst in the case of the D700 none of the choices of g.v.w. rating gives a true payload allowance of 7 tons.

Six-wheelers Also Available

As well as the models listed, there are two six-wheelers—one with a four-spring rear bogie, the other with two-spring rear suspension. These are designed by Ford, but will be assembled by All Wheel Drive Ltd. and County Commercial Cars Ltd. and will employ Eaton axles. The model designation is DT800 and the gross weight rating 38.00016. (17 tons) in both cases. The design with four-spring suspension is available as a 6 x 2 or a 6 x 4, whilst the two-spring model is made in 6 x 4 form only. With both types, the driving axles are two-speed units available in ratios of 6.5/9-04, 6.14/8.54 and 7.17/9.97 to 1 on the 6 x 4, and the first two only on the 6 x 2. On the 6 x 4 the bogie is an Eaton -30DT through-drive with a lockable inter-axle third differential. Bogie capacity is 30,000 lb. (13.4 tons) in each case and the braking is airassisted hydraulic—not a dual system as on the norrnal-duty D800.

Two Till Cabs

Because of the complexity of the range it is proposed to deal individually with the various units fitted and leave the table to illustrate the overall make-up of the separate models. However, one item, the cab, is standard throughout the range. There are actually two versions, both based on the same structure: one is the standard with normal fittings and trim. the other a luxury version called the Custom Cab. Following the current trend in British vehicle cabs the Ford design tilts forward for access to the engine and components and is a forward-entry type with steps ahead of the front wheels. The engine is located below the seat box so that there is free access across the cab. A double passenger seat can be accommodated.

Internally there is much more room than in the outgoing Trader normal-control models, but in spite of this the distance from the bumper to the back of the cab is only 60 in., 13 in. less than with the Trader cab. Even in standard form the interior trim and fittings are to a high standard. On the Custom Cab. which is standard on the DT800 and D800 lorry and tractive unit models, there is additional luxury with the driving seat adjustable for height as well as the normal foreand-aft adjustment, and the squab rake can be varied. Custom Cab seats have extra foam padding and are covered with a better quality PVC material than the standard model. A dual passenger seat is standard. The fully adjustable driving-seat mechanism and the dual seat can be supplied in most cases at extra cost with the standard version.

The cab has been designed to provide the best facilities for the driver. The windscreen is 5 ft. 8 in. wide and 2 ft. 1 in. deep to give excellent forward visibility, and 80 per cent is swept by electrically driven 20 in. wiper blades—the arm in front of the driver having a special two-arm actuation to

increase the coverage. The forward-hinged doors have wind-down windows and swivelling quarter lights, whilst at the rear of the cab there are three large windows, bringing the total glass area of the cab to 3,194 sq. in. A fresh-air heater unit is standard in Custom Cabs and optional on the basic model, and instrumentsconsist of speedometer and. fuel, vacuum or air, and water-temperature gauges. All lighting switches are mounted on the steering column,

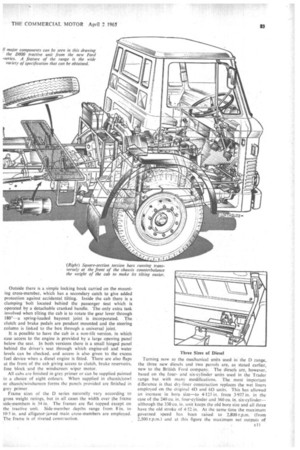

How It Tilts

The tilting mechanism consists of two counterbalancing transverse torsion bars at the front of the cha-Ssis frame in line with the mountings on which the cab pivots. A stay is provided to hold the cab in the fully-tilted position, the maximum angle being 45°. At, the front, the cab is supported on Metacone rubber/metal units carried on the pivots, whilst at the rear a single mounting is used, this being on an archshaped member going over the engine. The cab holding-down arrangement at the -rear consists of external and internal locks, Outside there is a simple locking hook carried on the mounting cross-member, which has a secondary catch to give added protection against accidental tilting. Inside the cab there is a clamping • bolt located behind the passenger seat which is operated by a detachable cranked handle. The only extra task involved when tilting the cab is to rotate the gear lever through 180°—a spring-loaded bayonet joint is incorporated. The clutch and brake pedals are pendant mounted and the steering column is linked to the box through a universal joint.

It is possible to have the cab in a non-tilt version, in which case access to the engine is provided by a large opening panel below the seat. In both versions there is a small hinged panel behind the driver's seat through which engine-oil and water levels can be checked, and access is also given to the excess fuel device when a diesel engine is fitted. There are also flaps at the front of the cab giving access to clutch, brake reservoirs. fuse block and the windscreen wiper motor.

All cabs are finished in grey primer or can be supplied painted in a choice of eight colours. When supplied in chassis/cowl or chassis/windscreen forms the panels provided are finished in grey primer.

Frame sizes of the D series naturally vary according to gross weight ratings, but in all cases the width over the frame side-members is 34 in. The frames are flat topped except on the tractive unit. Side-member depths range from 8 in. to 10.5 in. and alligator-jawed main cross-members are employed. The frame is of riveted construction.

Three Sizes of Diesel

Turning now to the mechanical units used in the D range, the three new diesels and two petrols are, as stated earlier, new to the British Ford company. The diesels are, however, based on the fourand six-cylinder units used in the Trader range but with many modifications. The most important dIference is that dry-liner construction replaces the wet liners employed on the ciriginal 40 and 613 units. This has allowed an increase in bore size—to 4-125 in. from 3-937 in. in the case of the 240 Cu. in, four-cylinder and 360 eu. in six-cylinderalthough the 330 eta, in. unit keeps the old bore size and all three have the old stroke of 4-52 in. At the same time the maximum governed speed has been raised to 2,800 r.p.m.. (from 2,500 r.p.m.) and at this figure the maximum net outputs Of the engines are 74 b.h.p. for the 240, 102.5 b.h.p: for the 330. and 113-5 b.h.p. for the 360 cu. in. units. Maximum net torque figures are 178 lb: ft. and 237.5 lb. ft. at 1,700 r.p.m. .for the 240. and 330 cu. in. units respectively, and 262 lb. ft. at 1,500 r.p.m. for the 360 cu. in. unit.

The, diesel engines are mounted in the chassis at an angle of 45° to the vertical (with the heads over to the left-hand side of the chassis) and because of this there are certain external changes, such as the fitting of a special sump and

re-positioning of certain components. Internally many changes have been incorporated, including a redesign of the timing gears; an increase of 0.125 in. in, the crank-pin diameter on the crankshaft used in the bigger-bore units; a different pistonring arrangement: an alteration to the water system with an increased-capacity water pump; and an increase in size of the inlet valves. There are many more internal changes and on the 360 Cu. in, engine a. CAV distributor-type fuel pump is employed, whilst on the 240 and 330 cu. in. units a Simms Minirnec in-line pump is used. A Ford/Autolite 38 amp, alternator is fitted and the starter is a Lucas M50 5 in. pre-engaged type.

Two Petrol Units The two petrol engines are six-cylinder units. Because overall height is less than on the diesels, they are mounted vertically in the chassis and take the place of the fourand six-cylinder petrol engines used in the Traders, which were based on the original diesel designs.

The engines have the same external dimensions in spite of a difference in cubic capacity—one is 240,cu. in, and the other 300 Cu. in. In both cases the bore is 4.0 in., the difference in capacity being effected by different stroke dimensions. On the 240cu. in. the stroke is 3.18 in.. and on the 300cu, in. it

is 3-98 in, Maximum output of the 240 en. in. engine is 105 b.h.p, net at 3,500 r.p.m., and the maximum net torque is 183 !bit. at 2.400 r.p.m. Comparable figures for the 300 cu. in. unit are 130 b.h.p. at 3,400 r.p.m. and 256 lb. ft. at 1,800 r.p.m. Both engines share many common parts and, as with the diesels, a 38 amp. alternator is standard.

Irrespective of the engines fitted, an identical type of cooling system is used to all models in'the D range. This is pressurized to 4 p.s.i. and a separate header tank having a filler can is employed to allow the system to be topped up without tilting the cab. The radiator is in all cases mounted immediately in front of the engine and the size of radiator varies according to the engine and the intended operating area of the vehicle. Varivane automatic, radiator shutters or manually operated radiator blinds are available.

Three sizes of clutch are used to cover the range, all being hydraulically actuated. With the 240 cu. in. petrol and diesel engines an 11 in. unit is standard, hut there is an optional 12 in. version. The 12 in.-diameter clutch is standard on the 330 cu. in. diesel and 300 cu. in. petrol, although with the latter engine a 13 in. clutch is fitted to 7and 7-5-ton heavy-duty tippers and .8-ton tippers. This 13 in. clutch can be specified instead of the 12 in., except in the case of D400 models, and is used without option with the, 360 cu. in. diesel engine.

Three gearboxes used.in the fl-series range are a Ford fourspeed and two Clark five-speed units. All three have synchror12 mesh engagement on all forward speeds except bottom, and the Ford unit is basically the same as the box used in Thames Trader models. The gear ratios are 6-398, 3-092, 1.686 and I to 1 forward, and 7.903 to I reverse.

It will be seen that this gearbox is fitted as standard, without option, on all models up to 13500 and is available in all models up to the D750 as an alternative to a Clark five-speed box. The two Clark gearboxes are the 2651 and 2621 five-speed, direct-top units, and they differ only in respect of ratios. The 2651 is basically the same as the Clark five-speed box used on some Trader models, but a number of modifications have been made to increase its life. Ratios are 7-58. 4-38, 2-40, 1-48 and I to 1 forward, and 7-2 to I reverse. The gearbox is recommended for use with single-speed axles. the 2621 unit having closer ratios to ensure better matching with the ratios of Eaton two-speed axles used in the range. For this reason the 2621 box is available only with two-speed axles and its ratios of 7.58, 4.10, 2.13, FI7 and I to I forward, and 7-2 to 1 reverse, give 10 distinct overall ratios Which would not be the case if the 2651 box were used with the two-speed axle.

The Axle Loadings The essential difference between the three capacities of front axle used on the D series is in the beam capacity. The 5.500 lb. and 7.500 lb. axles have 1-23-in.-diameter kingpins, whilst the 9.500 lb. version has kingpins of 1.43 in. diameter. The models on which the three types are used can be seen from the table, and only on the 11700 is there an option quoted. The two heavier capacity axles are suitable for the fitting of cast-spoke hubs for use with detachable rims.

Steering is also a fairly straightforward aspect of the new range. The steering box—'-a Cam Gears Ltd. worm-and-peg unit—is mounted rigidly to the chassis frame, the steering column being connected to it through a universal joint. On chassis with 5,5001h. and 7,5001b. front axles a 300Q gear is used, whilst a 350Q unit is used with 9.5001h. axles. Power assistance is available on all except 1)200. 1)300 and D400 chassis, this being by Hydrosteer hydraulic equipment; with this option a 300Q box is employed.

Ride and Location Suspension has been given an important position in designing the .D range in an attempt to provide a relatively soft ride with good anti-roll characteristics. Vehicles up to the D400 types and tractive units have conventional semi-elliptic springs at the • front and rear, but on the 1)500 and higher capacity load carriers an interesting new form of suspension is used at the rear. The main semi-elliptic springs are slipper ended with axle location by half-length, two-leaf springs located underneath them and shackled to the underside of the forward spring brackets. The portions of the spring brackets that the ends of the main springs bear on are radiused so that a variable rate effect is obtained. As the load is applied, so the effective length of the springs reduces by a maximum of 9.5 in. between the laden and unladen conditions. This feature eliminates the need for helper springs in most cases, although these are offered.

There are two basic sizes of front spring-4 ft. by 2.5 in. and 4 ft. 9 in. by 3 in., but these are available with a variety of load ratings to suit the numerous gross weight limits of the different models. Similarly there are three basic rear springs, shackle ended 4 ft. 4 in, by 3 in. for D200. D300 and 0400 chassis, and 3 ft. 9 in by 3 in. for tractive units, and 4ft. 8 in. (reducing to an effective length of 3ft. 11-5 in. when fully laden) by 3 in. radius-leaf springs for 13500 load carriers and above. Telescopic dampers are standard at the front axles of 0200, D300 and tractive-unit models and tippers. and at the rear also of heavy-duty tippers. They are available as optional equipment at front and rear .of all other models except that they cannot be fitted to tractive-unit or DT800 rear axles.

One of the biggest variations in the D range is in respect of rear axles. Four single-speed units and two two-speed axles have been developed specially for the range. and, apart from variation in carrying capacity, there are many variations in axle ratio possible. As with the front axles, rear axles on 0600 to D800 models are suitable for use with cast-spoke detachablerim wheels. Four sizes of crown wheels are also made12'625 in. spiral bevel for up to five tanners, 13.875 in. hypoid bevel for normal-duty vehicles of 6 tons and over. 14.875 in. spiral bevel for heavy-duty work and a 16 in. spiral bevel for extra-duty applications. As will be seen from the tables, axle capacities range from 13,000 lb. to 19,500 lb. The lightest axle is the 13A, with a 12.625 in. crown wheel, which can carry 13,000 lb. Next is the 148, with 13-875 in. crown wheel available with load ratings of 15,000 lb., 16,500 lb., and 18,500 lb., it is the widest used axle, being available in all vehicles from the 0400 to D750. The highest capacity single-speed units are the 15C, with a 14.875 in_ crown wheel, and the 1770, with a 1610, crown wheel. The 15C is for normal duty, whilst the 1770 is for arduous work and has an Eaton driving head. The two-speed axles are the Eaton 13802 13-75 in., which is generally available as optional wherever the Ford 148 axles of 15.000 lb. or 16.500 lb, are used, and the Eaton 16802 14-75 in.. which has a capacity of 19,500 lb, and can be used in place of the Ford 15C. Both the two-speed axles have Ford casings and the particular axle which can be specified depends in most cases on the engine and gearbox as well as on the load capacity.

6

The brake units used on the new models are of Girling manufacture, these being the new designs announced by that company at the Commercial Motor Show last year. There are four basic types of unit—the Uni-Servo leading-and-trailing-shoe type, the Duo-Servo and the HLS/S and H2LS two-leading-shoe types. The Duo-Servo unit is used at the rear of the 0200 and D300 and has a high self-servo action with floating brake shoes, giving the result that the leading shoe in each direction of ti:avel helps to apply the secondary shoe.

The Uni-Servo brake is basically the same as the Duo-Servo except that it has a single-piston wheel cylinder instead of a 'two-piston unit and gives a single-leading-shoe effect forwards and two-trailing-shoe action in reverse. It is used on the front wheels of the D200 only. All other fl-series models have FILS/S front and H2LS rear brakes. These range in size from 13 in. by 3 in. to 15-25 in. by 4-25 in. at the front and from 13 in. by 5 in. to 15-5 in. by 6 in. at the rear. On the 0200 the front brakes are 13 in. by 2-25 in. and 12.125 in. by 3 in. at the rear; on the D300 the sizes are 13 in, by 3 in. at the front and 12-125 in. by 4 in. at the rear. On all models the handbrake is mechanical without servo assistance, and with each of the six cylinder diesel engines an exhaust brake is optional.

Vacuum or Air Brakes

On most models there is a choice of vacuum or air-pressure assistance and at the top end of the scale—above D500-there is the choice of a dual system, this being standard on D800 rigids. Various types of Clayton Dewandre actuating systems are exclusively used according to the model and capacity. Vacuum servos are Hydrovac-type, suspended-vacuum units. whilst air assistance is provided by Airpakservos. With the dual-brake system. the hydraulic master cylinder is of the tandem type and is directly mounted to a tandem air-pressure actuator. The two sides of the master cylinder serve the front and rear brake hydraulic circuits separately and the actuator is fed by separate air systems to each part. This means that a single failure in the hydraulic lines will still leave the brakes on one axle serviceable, and a failure in the air system will not mean a complete loss of braking.

All the lighter fl-series models—up to the D500—have 16 in. two-piece wheels as standard, with the option of 20 in. wheels on all except the 13500 tractive unit. From the D600 upwards 20 in. three-piece wheels are standard, with the option of wheels • of the cast-spoke type.

As stated earlier, 38 amp. alternators are used on all models, but there is an option of a CAV 55 amp, alternator with diesel engines. A 12 V system is used in all eases. standard batteries being 120 a.h. with diesel engines and 57 a.h. with petrol. There are options of 185 a.1.1. with four-cylinder diesel engines. 240 a.h. with six-cylinder diesel and 120 a.h. with petrol. Various fuel tanks are available, the smallest being 14 gal. capacity and the largest 50 gal. The size fitted as standard varies with ate models.