Moving-bulkhead Bulkers

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

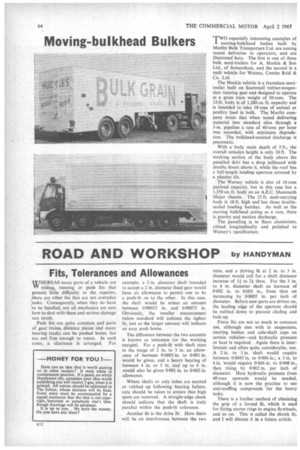

TW0 especially interesting examples of moving-bulkhead bodies built by Murfitt Bulk Transporters Ltd. are among recent deliveries to operators, and are illustrated here, The first is one of three bulk semi-trailers for A. Huckle & Son Ltd., of Somersham, and the second is a malt vehicle for Watney, Combe Reid & Co. Ltd.

The FIuckIe vehicle is a frameless semitrailer built on Scammell rubber-suspension running gear and designed to operate at a gross train weight of 30 tons. The 33-ft. body is of 1,280 cu. ft. capacity and is intended to take 18 tons of animal or poultry feed in bulk. The Murfitt company states that when tested delivering material into standard silos through a 5-in, pipeline a rate of 40 tons per hour was recorded, with minimum degradation. The bulkhead-assisted discharge is pneumatic.

With a body main depth of 5 ft.; the overall unladen height is only 10 ft. The working section of the body above the panelled skirt has a drop tailboard with double doors above it, while the roof has a full-length loading aperture covered by a plastics tilt.

The Watney vehicle is also of 18 tons payload capacity, but in this case has a 1,350 cu. ft. body on an A.E.C. Mammoth Major chassis. The 25 ft. malt-carrying body is 18 ft. high and has three doublesealed loading hatches. As well as the moving bulkhead acting as a ram, there is gravity and suction discharge.

The panelling is in Baco aluminium, ribbed longitudinally and polished to Watney's specification.