How Berlin Supplies its Buses with Compressed Gas

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

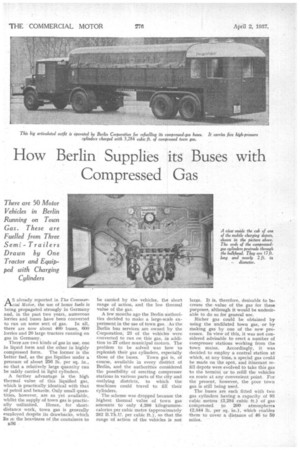

There are 50 Motor Vehicles in Berlin Running on Town Gas. These are Fuelled from Three SemiTrailers Drawn by One Tractor and Equipped with Charging

Cylinders

AS already reported in The Commercial Motor, the usc of home fuels is being propagated strongly in Germany and, in the past two years, numerous lorries and buses have been converted to run on some sort of gas. In all, there are now about 400 buses, 600 lorries and 20 large tractors running on gas in Germany.

There are two kinds of gas in use, one in liquid form and the other in highly compressed form. The former is the better fuel, as the gas liquifies under a pressure of about 256 lb. per sq. in., so that a relatively large quantity can be safely carried in light cylinders.

A further advantage is the high thermal value of this liquified gas, -which is practically identical with that of petrol and benzole. Only small quantities, however, are as yet available, whilst the supply of town gas is practically unlimited. Hence, for shortdistance work, town gas is generally employed despite its drawba.cks, which lie w the heaviness of the containers to

be carried by the vehicles, the short range of action, and the low thermal value of the gas.

A few months ago the Berlin authorities decided to make a large-scale experiment in the use of town gas. As the Berlin bus services are owned by the Corporation, 23 of the vehicles were converted to run on this gas, in addition to 27 other municipal motors. The problem to be solved was how to replenish their gas cylinders, especially

those of the buses. Town gas is, of course, available in every district of Berlin, and the authorities considered the possibility of erecting compresser stations in various parts of the city and outlying districts, to which the machines could travel to fill their cylinders.

The scheme was dropped because the highest thermal value of town gas amounts to only 9,200 kilogrammecalories per cubic metre (approximately 262 B.Th.U. per cubic ft.), so that the range of action of the vehicles is not

large. It is, therefore, desirable to Increase the value of the gas for these purposes, although it would be undesirable to do so for general use.

Richer gas could be obtained by using the undiluted town gas, or by Making gas by one of the new processes. In view of this, it was not considered advisable to erect a number of compresser stations working from the town mains. Accordingly, it was decided to employ a central station at which, at any time, a special gas could be made on the spot, and itinerant refill depots were evolved to take this gas to the termini or to refill the vehicles en route at any convenient point. For the present, however, the poor town gas is still being used.

The buses are each fitted with two gas cylinders having a capacity of 93 cubic metres (3,284 cubic ft.) of gas compressed to 200 atmospherea (2,844 lb. per sq. in.), which enables them to cover a distance of 46 to 50 miles. The Corporation has taken into service for the present a tractor with three refill semi-trailers, each of which carries, lengthwise, five large high-pressure gas cylinders supported in felt-lined brackets and measuring about 17• ft. by 1 ft. 10-i ins. These contain 1,570 cubic metres (55,447 cubic ft.) of gas compressed to 350 atmospheres (4,978 lb. per sq. in.).

The cylinder heads protrude into a cabin at the rear, where the necessary apparatus and dials are arranged. There are four fittings, one at each corner of these semi-trailers, for the connection of the flexible charging pipes leading to the cylinders of the vehicles. These can be recharged from the large cylinders in under five minutes ; that is, in no more time than would be required for refuelling with liquid fuels.

The charging cylinders can be emptied of 82 per cent. of their contents. The procedure generally, when refuelling, is always, first to tap the cylinder with the lowest pressure. If this were not done, too much highpressure gas would remain. When the vehicle cylinders are empty, they are almost down to atmospheric pressure, so that practically the slightest overpressure in the refill cylinders can be transferred to them.

In this way the refill cylinders can also be emptied down to a low pressure. When one is virtually exhausted the next cylinder is switched on, with its higher pressure, and so on in turn with the others.

The central compressor station is equipped with two large compressors, which, together, compress 340 cubic metres (12,007 cubic ft.) of gas per. hour. The gas is taken from the town main, and passed through a filter, tt extract dust. Then, via a rotary-piston type meter, it enters the compressors where it is compressed in five stages to 29,8, 142.2, 497.8, 1,422.2 and lastly, 4,978 lb. per sq. in. (2.1, 10 35, 100 and 350 atmospheres).

Between the compression stages th• gas is cooled. Also, it is passed afte each stage through a cleaner, wher oil and condensed water are extracted The highest temperature the ga reaches in this process is 110 degrees C It leaves the plant, however,. coolet down to 15 degrees C. Thence it i conducted direct to the filling taps 01 the spot or into the storage cylinders which together have a volume of 132.. cubic ft. (water volume), To charg one of the semi-trailers with its fly large cylinders occupies a period of fou hours.