ANEW TRACK-LAYING MACHINE Weighing Under Two Tons.

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

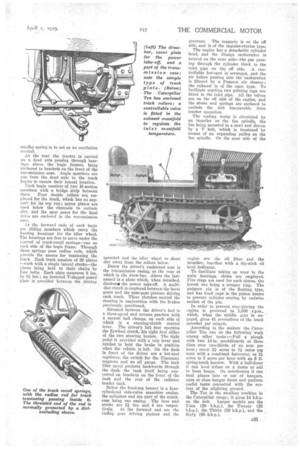

KNOWN as the Caterpillar Ten is a simple track-laying machine just introduced to the British market. It is produced by the Caterpillar Tractor Co., of San Leandro, California, successor to the Holt Manufacturing Co., and handled in this country by Tractor Traders, Ltd., Thornycroft House, Smith Square, London, S.W.1.

Naturally, the princi, pal .classes of use to which this machine can be put are agricultural; it can be also of great service to market gardeners who have reasonably large areas to cover, because it is capable of handling ploughs and cultivating implements of medium size in the rather confin;ed areas which are usual in the cir cumstances. In a later paragraph its scope for various types of job is , outlined.

The Caterpillar Ten is, so named by reason of its nominal horse-power. Its price in England is f320. The overall length is 8 ft. 4 ins. and the overall width just under 4 ft. To the top of the radiator can the overall height is 4 ft. 3 ins. .The weight, we understand, is approximately 1 ton 15 cwt. The gearbox provides three forward speeds, providing approximately 2 m.p.h., 2.6 m.p.h. and 4.33 m.p.h.; reverse giving about 2 m.p.h.

Steering is accomplished by means of a clutch and a band brake for each track; thus when it is desired to turn to the left the left track clutch is disengaged and the brake applied on that side, the right-hand track continuing the drive. If desired the machine can turn in its own length.

No frame, in the proper sense of the term, is employed, the engine, gearbox and transmission casing being bolted together to form a unit which supports all the other parts of the vehicle. This unit in tarn is carried on the two track bogies; the forward end is supported on a transverse semi-elliptic spring, which is bolted to the underside of the engine base. The ends of the spring are carried on shackles on the track bogie frames, and there is also a shorter semi-elliptic spring below the main one which is shackled to bearers on the clutch pit. The purpose of the smaller spring is to act as an oscillation control.

At the rear the tractor is carried on a dead axle passing through bearings above the bogie frames, being anehored to brackets on the front of the transmission case. Angle members are run from the dead axle to the track bogies to ensure their lateral location.

Each bogie consistsof two H-section members with a bridge strip between them. Four double rollers are employed for the track, which has no support for its top run; apron plates are used below the channels to exclude dirt, and the spur gears for the final drive are enclosed in the transmission case.

At the forward ends of each bogie are sliding members which carry the hearing housings for the idler wheel. The housings are free to move under the control of track-recoil springs—one on each side of the bogie frame. Through these springs pass radius rods, which provide the means for tensioning the track. Each track consists of 29 plates —each with a single lateral strake—the plates being held to their chairs by four bolts. Each plate measures 8 ins. by 61 inn; an,inverted V-shaped guard' plate is provided between the driving sprocket and die idler wheel to shoot dirt away from the rollers below.

Below the driver's cushioned seat is the transmission casing,' at the rear of which is the draw-bar. Above the lastnamed is a plate which, when detached, discloses the power take-off. A multidisc clutch is employed between the bevel gears and the spur-gear pinions driving each track. These clutches control the steering in conjunction with the brakes previously mentioned.

Situated between the driver's feet is a three-speed and reverse gearbox with a central ball change, on each side of which is a steering-clutch control lever. The driver's left foot operates the flywheel clutch, his right foot either of the two steering brakes. The right pedal is provided with a trip lever and ratchet to hold the brake in position when the vehicle is left. On the dash in front of the driver are a hot-spot regulator, the switch for the Eisemann magneto and an oil gauge. The tank filler spout projects backwards through the dash, the tank itself being sup'ported on brackets on the front of the dash and the rear of the radiator header tank.

Below the fixed-top bonnet is a fourcylindered side-valve monobloe engine, the cylinders and top part of the crankcase being one casing. The bore• and stroke are 31 ins. and 4 ins. respectively. At the forward end are the timing gear driving pinions and the

governor. The magneto is on the off side, and is of the impulse-starter type.

The engine has a detachable cylinder head, and the Ensign carburetter is located on the near side—the gas passing through the cylinder block to the inlet pipe on the off side. A controllable hot-spot is' arranged, .and the air before passing into the ' carburetter is filtered by a Pomona air cleaner; the exhaust is of the open type. To facilitate starting two priming taps are fitted in the inlet pipe. All the valves are on the off side of the engine, and the stems and springs are enclosed to exclude the dirt inseparable from tractor operation.

The cooling water is circulated by an impeller on the fan spindle, the fan being mounted in a cowl and driven by a V belt, which is tensioned 'by means of an expanding pulley on the fan spindle. On the near side of the engine are the oil filter and the breather, together with a dip-stick oil level indicator.

To facilitate taking up wear in the main bearings, shims are employed. Five rings are used for each piston, the lowest one being a scraper ring. The gudgeon pin is of the floating type, and has fixed caps in the piston bosses to prevent cylinder scoring by endwise motion of the pin.

In order to prevent over-driving the engine is governed to 1,500 r.p.m., which, when the middle gear is engaged, gives 41 revolutions of the track sprocket per minute.

According to the makers the Caterpillar Ten can do the following work tunong • other tasks :—Pull a plough with two 14-in. mouldboards or three discs over two-thirds, of an acre per hour ; cover 21 acres to 31 acres per hour with a combined harvester, or 21 acres to 3 acres per hour with an 8 ft. spring-tooth harrow. With a bull-dozer it can level refuse on a dump or soil in loose heaps. On aerodromes it can haul planes into or out of hangars, open or close hangar doors and perform useful tasks connected with the surface of the alighting ground. .

The Ten is the smallest machine in the Caterpillai range; it gives .14 b.h.p. on the belt: Larger models are the 2-ton (20 b.h.p.), the Twenty (25

b.h.p.), the Thirty (30 and the Sixty (60 b.h.p.).