Eom Drivers &Mechanics TEN SHILLINGS WEEKLY is paid for the

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

best corn. mmication received, and one penny a line of ten words for anything else published, with an allowance for photographs.

Send us an account of any special incident of your work or experience. If suitable, we will edit your notes, supply a sketch when required, and pay you for everything Published. Mention your employer's name, in confidence, as evidence of good faith. Address to The Editor, Tiiz COmmEuciAL MOTOR, Rosebery Avenue, London, E.G.

Light Up Your Lamps At

7.32, Thursday ; 7.34, Friday ; 7.35, Saturday ; 7.38, Monday ; 7.39, Tuesday ; 7.41, Wednesday.

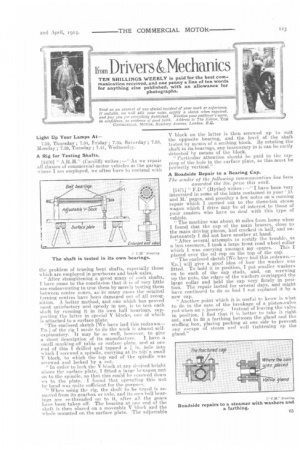

A Rig for Testing Shafts.

[1470[ " A.14.11." (Cardiff) writes :—" As we repair all classes of commercial-motor vehicles at. the garage where I am employed, we often have to contend with

the problem of trueing bent. shafts, especially those which are employed in gearboxes and hack axles. "After straightening a great many of -such shafts, T have come to the conclusion that it is of very little use endeavouring to true them by merely testing them between centre cones, as in many cases the original turning centres have been damaged out of all recognition. A better method, and one which has proved most satisfactory and speedy in use, is to test each shaft by running it in its own ball bearings, supporting the latter in special V blocks, one of which is attached to a surface plate.

"The en-closed sketch [We have had this redrawn.— Fn.] of the rig I made to do the work ia almost selfexplanatory. It may he as well, however, to give

a. short description of its manufacture. I have a small marking-oft table or surface plate, and at one end of this I drilled and tapped a ; in.. hole into which I screwed a spindle, carrying at its to-p-a small V block, to which the top end of the spindle was screwed and locked by a, mit.

"In order to lock the V block at any desired height above the surface plate, I fitted a large hexagon nut on to the spindle, so that this could he screwed down on to the plate. I found that operating this nut by hand was quite sufficient for the purpose.

" When using the rig, the shaft to be trued is removed from its gearbox or axle, and its own bon bearings are re-threaded on to it, after all the gears have been taken off. The bearing at one end of the shaft is then placed on a moveable V block and the whole mounted on the surface plate. The adjustable V block on the latter is then screwed up to suit the opposite bearing, and the level of the shaft tested by means of a scribing block. By rotating the shaft in its bearings, any inaccuracy in it can be easily detected by means of the block. " Partieular attention should be paid to the tapping of the hole in the surface plate, asthis must be perfectly vertical."

A Roadside Repair to a Bearing Cap.

The sender of the following communication has been • awarded the 10s. prize this week.

[1471] " F.D." (Elythe) writes :—" I have been very interested in some of the hints contained in your D. and M.' pages, and possibly a few notes on a running repair which 1 carried out to the three-ton steam wagon which I drive may be of interest to those of your readers who have to deal with this type of vehicle.

"The machine was about.40 miles from home when I found that the cap of the main brasses, close to the main driving pinion, had cracked in half, and unfortunately I did net have another at hand. "After several attempts to rectify the trouble, as a last resource, I took a large front road wheel collar which I was carrying amongst my spares. This I placed over the oil cup on the top of the cap. "The enclosed sketch [We have had this redrawn.— ED.] will give a goed idea of how the washer was fitted. To hold it in position, I put smaller washers on to each of the cap studs, and, on screwing up the nuts, the edges of the washers overlapped the large collar and held the cap very firmly in position. The repair lasted for several days, and might have continued to do so had I not repladed it by a new cap. " Ancther point which it is useful to know is what to do in the case of the breakage of a.piston-valve rod when on a journey. Instead of leaving the valve in position, I find that it is better to take it right out, and to fit a farthing between the gland and the stuffing box, placing packing at one side to prevent any escape of steam and well tightening up the gland."