Larger Land-Rover Diesel Engine

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

SUPERSEDING the company's 2-litre oil engine for application to all types of Land-Rover, a new 21-litre diesel engine was announced on Wednesday by the Rover Co., Ltd., Solihull, Warwickshire, which has an output of 62 b.h.p. at 4,000 r.p.m., compared with 51.2 b.h.p. at 3,500 r.p.m., produced by the smaller engine. Whereas the maximum torque output of the 2-litre engine is 87 lb.-ft. at about 2,500 r.p.m., the new unit develops

103 lb.-ft. at 1,800 r.p.m., corresponding b.m.e.p.s being 104 p.s.i. and Ill p.s.i., respectively.

The larger engine has an improved specific fuel consumption at higher speeds, and its " falling-torque " curve gives a torque back-up characteristic on the road which is favourable to the performance of the vehicle in all the gears. Cylinder block, crankshaft and many smaller components are identical to those of the 21-litre petrol engine.

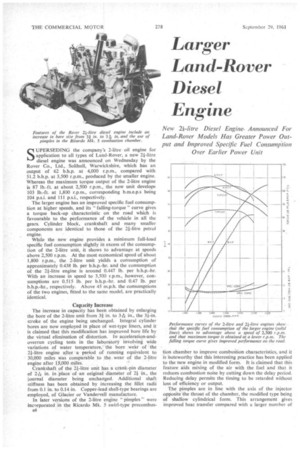

While the new engine provides a minimum full-load specific fuel consumption slightly in excess of the consumption of the 2-litre unit, it shows to advantage at speeds above 2,500 r.p.m. At the most economical speed of about 1,800 r.p.m., the 2-litre unit yields a consumption of approximately 0.438 lb. per b.h.p.-hr. and the consumption of the 21-litre engine is around 0.447 lb. per b.h.p.-hr. With an increase in speed to 3,500 r.p.m., however, consumptions are 0.515 lb. per b.h.p.-hr. and 0.47 lb. per b.h.p.-hr., respectively. Above 45 m.p.h. the consumptions of the two engines, fitted to the same model, are practically identical.

Capacity Increase The increase in capacity has been obtained by enlarging the bore of the 2-litre unit from 31 in. to 3-11 in., the 31-in. stroke of the engine being unchanged. Integral cylinder bores are now employed in place of wet-type liners, and it is claimed that this modification has improved bore life by the virtual elimination of distortion. In acceleration-andoverrun cycling tests in the laboratory involving wide variations of water temperature, the bore wear of the 21-litre engine after a period of running equivalent to 30,000 miles was comparable to the wear of the 2-litre engine after 15,000 miles.

Crankshaft of the 21-litre unit has a crank-pin diameter of 24 in. in place of an original diameter of 21 in., the journal diameter being unchanged. Additional shaft stiffness has been obtained by increasing the fillet radii from 0.1 in. to 0.14 in. Copper-lead shell-type bearings are employed, of Glacier or Vandervell manufacture. In later versions of the 2-litre engine " pimples " were incorporated in the Ricardo Mk. 5 swirl-type precombus88 tion chamber to improve combuaion characteristics, and it is noteworthy that this interesting practice has been applied to the new engine in modified form. It is claimed that this feature aids mixing of the air with the fuel and that it reduces combustion noise by cutting down the delay period. Reducing delay permits the timing to be retarded without loss of efficiency or output.

The pimples are in line with the axis of the injector opposite the throat of the chamber, the modified type being of shallow cylindrical form. This arrangement gives improved heat transfer compared with a larger number of

tapered pimples fitted to the combustion chamber of the 2-litre engine. Because of their high temperature, the tips of the pimples act as igniters for each new charge.

Easier starting at very low temperatures is also provided by the pimples, tests having been made with temperatures of minus 20° C. to minus 30° C. Practically instant starting is obtainable at the higher temperature at a mean cranking speed of 100 r.p.m. after a 10-second glow-plug period, and at minus 30° C. delay is increased by only 2 seconds. In both cases starting is achieved without breaks in the firing order.

A speed-sensitive automatic advance mechanism, covering a range of 10° of crankshaft rotation, is now a standard feature of the C.A.V. distributor-type pump fitted to the engine. It is claimed that engine operation is relatively insensitive to variations in cetane number.

Pistons haVing modified crown shapes give an increase in compression ratio from 221 to 1 to 23 to 1, the crown being of V-trough form. Matched to the characteristics of the pimpled combustion chamber, the crown provides a "less critical " nozzle performance.

Freedom from injection-pipe scaling is afforded by the use of pipes comprising three Bundy wrapped tubes. surfaced with copper, which forms the bore of the pipes. Internal diameter of the pipes is 2 mm., whilst the outside diameter is 6 mm. Injection-pump plunger diameter has been increased from 6 mm. to 6.5 mm. Other features that give increased enairte life include exhaust valves of EN54 steel having Stellited stem tips and Brimochrome seats. Modifications to the valve gear, include the use of a onepiece rocker shaft. Increases in b.m.e.p.• and torque outputs arc partly attribUted to the use of a tuned inlet manifold of the end-feed type. In extensive laboratory tests, an experimental manifold was equipped with a piston at the end of the gallery to study the effect of changes in "overhang," and flexible rubber pipes were used for connections between the gallery and the engine. Changes were also made in the length of hose between the air cleaner and manifold, and tests were repeated with many permutations of gallery bore diameter, pipe size and so on.

Development work also included experiments in co-operation with George Angus and Co_ Ltd., with oil seals for the, flywheel end of the engine. As a result of these experiments a seal was produced for both diesel and petrol engines, which is. completely effective under arduous operating conditions and can cater for 'slopes up to 30° severity. The seal is of the single-split, single-lip, garterspring type and is resistant to overheating when the engine is being run-in.

Detailed features include the use of a sump with a stiffened flange and of a flywheel giving an increase in inertia of 8 per cent. A big-bore air cleaner, a radiator of greater capacity and a larger cooling fan are now employed, location of the fan being approximately on the centre line of the radiator. The water pump has been transferred to a higher level on the cylinder block and one of the batteries has been removed from its normal place behind the radiator to a space under the seat.

The original Lucas C.45-type generator has been replaced by a C.40 type of the same output which affords a saving in weight and reduces space requirements.