RIGID SIX-WHEELERS FOR MEDIUM LOADS.

Page 11

If you've noticed an error in this article please click here to report it so we can fix it.

Two New Renault Models of Three and Four Tons Capacity Standardized for Goods and Passenger Transport.

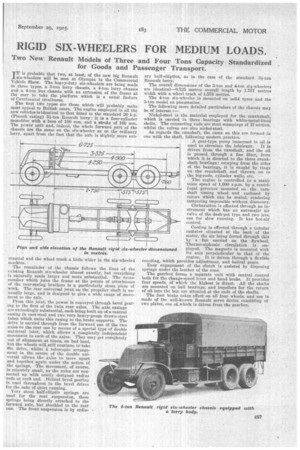

ITis probable that two, at least, of the new big Renault six-wheelers will be seen at Olympia in the Commercial Vehicle show. The heavy-duty six-wheelers are being made in three types, a 3-ton lorry chassis, a 4-ton lorry chassis and a 4-ton bus chassis with an extension of the frame at the rear to take the platform which is a usual feature of Continental omnibuses.

The first tvh, types are those which will probably make most appeal to British users. The engine employed in all the new vehicles isidentical'to that fitted to the standard 20 h.p. (French rating) 34-ton Renault lorry; it is a four-cylinder monobloc with a bore of 100 mm. and a stroke of 160 mm. The power unit and, indeed, the whole forward part of the chassis are the same on the six-wheeler as on the ordinary lorry, apart from the fact that the axle is slightly more sub stantial and the wheel track a little wider in the six-wheeled machine.

The remainder of the chassis follows the lines of the existing Renault six-wheeler almost exactly, but everything is naturally made larger and mere substantial. The crossmember which joins the frame at the points of attachment. of the rear-spring brackets is a particularly stout piece of work. The rear universal joint on the' propeller shaft is unusually large, and is designed to give a wide range of movement to the axle.

From this joint, the power is conveyed through bevel gear ing to the first of the twin rear axles. The axle casings are exceedingly substantial, each being built up of a central casing in cast-steel and two very heavy-gauge drawn-steel tubes which unite this casing to the brake supports. The drive is carried through from the forward one of the two ;isles to the rear one by means of a special type of double universal joint, which allows a completely independent movement to each of the axles. They may get completely out of alignment at times, on bad land, but the wheels will still continue to take the drive, whilst a telescopic arrangement in the centre of the double universal allows the axles to move apart and together again under the action of the springs. The movement, of course, is minutely small, as the axles are connected up with neatly designed radius rods at each end. Helical bevel gearing is used throughout in the bevel drives for the sake of quiet running.

Very stout half-elliptic springs are used for the rear suspension, these springs being directly attached to the forward axle, but shackled to the rear one. The front suspension is by ordin• ary half-elliptics, as in the case of the standard 81-ton Renault lorry.

The overall dimensions of the 3-ton and 4-ton six-wheelers are identical-6.725 metres overall length by 1.757 metres width with a wheel track of 1.575 metres.

The 4-ton six-wheeler is mounted on solid tyres and the 3-ton model on pneumatics..

The following more detailed particulars of the chassis may be of interest:— Nickel-steel is the material employed for the crankshaft, which is carried in three bearings with white-metal-lined shells: The connecting rods are steel stampings of H section, whilst the valves are also nickel-steel. • As regards the camshaft, the cams on this are formed-in one with the shaft, following modern practice.

A gear-type pump immersed in oil is used to circulate the lubricant. It is driven from the camshaft, and the oil is passed through a fine filter, from which it is directed to the three crankshaft bearings ; escaping from the sides of the bearings, it is caught by rings on the crankshaft and thrown on to the big-ends, cylinder walls, etc.

The engine is controlled to a maximum speed of 1,600 r.p.m. by a centrifugal governor mounted on the camshaft timing wheel and enclosed by covers which can be sealed, rendering tampering impossible without discovery.

Carburation is effected through an instrument which has an automatic air valve of the dash-pot type and two jets, one for slow running. It has hot-air control. • Cooling is effected through a tubular radiator situated at the back of the motor, the air being forced through this by a fan carried on the flywheel, Thermo-siphonic circulation is employed. The magneto is mounted with its axis perpendicular to that of the engine. It is driven through a flexible coupling, which provides adjustment, and helical gears.

Easy engagement of the clutch is assisted by disposing springs under the leather of the cone.

The gearbox forms a separate unit with central control both for the change-speed lever and hand brake. It provides four speeds, of which the highest is direct. All the shafts are mounted on ball bearings, and impellers for the return of oil into the box are situated at the ends of the shafts.

The foot brake takes effect on all four wheels, and use is made of the well-known Renault servo device consisting of two plates, one of,whieh is driven from the gearbox.