Lower

Page 42

Page 43

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

Load

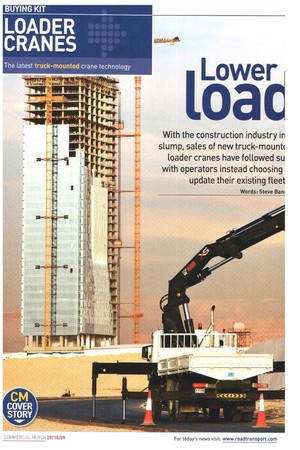

With the construction industry in slump, sales of new truck-mount( loader cranes have followed su with operators instead choosing update their existing fleet

Words: Steve Baru

Hit by the steep downturn in the building trade, sales of truck-mounted loader cranes have plummeted this year.

"The market is down by approximately 60% to 70% compared with 2008," says Hyva (UK) managing director Tony Davies.

"We usually sell 100 PM loader cranes a year," says Tracie Sharratt, responsible for sales at Tamworth, Staffordshire, dealer Central Hydraulic Loaders. "Models rated at more than 20 tonne/metre (t/m) account for 80% of our business and mainly go to the construction and rail industries, If we find buyers for 40 loaders this year though, we'll he pleased. Demand is more than 50% down," she adds.

At least this means that customers should not have to wait too long for their loaders to be delivered. -Lead times are now typically no more than four or five weeks,says Fassi (UK) sales manager Peter May.

Sluggish demand means that anybody in a position to buy a loader crane should be able to negotiate a keen deal in what May says has become a price-driven market: and not just on new equipment.

"Some good-quality used examples are coming onto the market as fleets cut back and dispose of vehicles," Sharratt says. Demand for them is buoyant compared with the demand for new tackle, she says.

"We're also finding that people are upgrading their existing equipment, adding extensions and remote controls," she adds "Nor is there any indication that operators are skimping on maintenance, and that's good news for us, given that we do about ilm-worth of parts and service business annually."

Purchasing new now, if you can afford it, makes sound sense because prices are only going one way upwards. Virtually all loader cranes sold in Britain are made in Continental Europe's eurozone. As importers dispose of existing stock, and start to place orders with suppliers, they are liable to find prices have gone up because of the euro's strength against the pound. Any increases will have to be passed on either partly or as a whole to the customers.

Mandatory changes in loader design are likely to drive prices up too, probably by about 3% to 4%.

New EU regulations

All loader cranes manufactured from 2010 and sold in the European Union with a rated capacity of 1,000kg or more, or a maximum net lifting moment of 40,000Nm or above approximately 4.0t/m will have to be fitted with stabiliser interlocks. They will, effectively, adjust your crane's lifting capacity in line with the extent to which the stabilisers are deployed.

If they are not deployed sufficiently, capacity will decrease to ensure that truck, crane and load do not topple over. Completely inadequate deployment means that the crane will not operate at all.Timber cranes are exempt from this requirement.

Tough economic times have not stopped loader crane makers introducing new products and improving existing models, however.

Last December, Hiab unveiled the 80t/m capacity XS 855. With a potential lifting height of more than 30m, it is said to increase speed by more than 30% and lift productivity by more than 20% compared with previous models.

Nor is Hiab ignoring the lighter end of the market. Last March saw the launch of the XS 022,033, and 044. Designed with builders' merchants in mind, they fall into the 2t/m to 4t/in category and are available with up to four extensions, depending on the model.

In a bid to cut fuel usage and CO2 emissions, Hiab is offering buyers of its HiPro loaders the chance to specify a variable rather than a fixed displacement pump. Admittedly, it adds about £1,000 to £2,000 to the final invoice, but Hiab argues that it can cut fuel usage and CO2 emissions by as much as 32% if fitted to, for example, an XS 288 HiPro. and should pay for itself in about 18 months. A further advantage is that a variable pump keeps oil temperature down, which means that, in most cases, there is no need to fit a separate cooler.

Hiab has also launched the eight-lever radio remotecontrol CombiDrive2 to use with selected cranes in the HiPro line-up with more than six hydraulic functions; when fitted with a jib and a hoist for example.

Radio remote control is becoming increasingly popular across the marketplace and is standard on many models.

"About 40% of the loaders we supply are fitted with it," says Ismo Leppanen, director of industrial business, Europe, the Middle East and Africa at Cargotec. which owns the Hiab brand. "It allows the loader operator to stand in a safer, quieter area away from the vehicle and avoid any exhaust fumes."

A radio remote makes it easier for operators to see

what they are doing and place the load precisely, and to avoid any risk of slipping or falling while clambering up and down from a seat mounted on the loader itself.

Hiab has been working with tipper specialist Boweld to develop a kit system that will provide customers with an xTR Bucket Crane and a tipper body in less than three weeks. It relies on a subframe Boweld has developed that simplifies the crane's installation.

Fassi-nation

Hiab rival Fassi has come up with four new continuousrotation Evolution loaders in the 29t/m to 36t/m category with radio remote control as standard.

The secondary boom can rise 15" above the horizontal to make it easier to manoeuvre machinery through a door or window or work in places where the overhead clearance is restricted.

Evolution cranes offer precise control of the speed of the loader relative to the load, says the manufacturer.

The aim is to ensure smooth operation however rough the driver is with the controls and to prevent whatever is being lifted bouncing around.

If specified with radio control. smaller Fassi models with a capacity from 5t/rn can be ordered with the XP — eXtra Power— system. A familiar option on the manufacturer's larger loaders, when required, it can boost lifting capacity by 10% while simultaneously reducing the speed of the loader's movements.

Also. Fassi has been busy introducing three big loaders with capacities of 56t/m. 66t/m and 95t/m with standard radio control.

Marketed under the 950AXP banner, the latter can be ordered with up to eight extensions and six extra fly jibs.

Having launched its new range of loaders at the European Road Transport Show in Amsterdam in 2007, Hyva started selling them in the UK about a year ago. "That was about the time demand began to spiral downwards.recalls Davies ruefully.

Its line-up stretches from him to 80t./m and its biggest model is on offer with no less than 10 hydraulic extensions. Hyva still remains better known, however, for its tipping rams, hook loaders and skip loaders.

HMF is busy promoting a new series of mid-range loaders 16 models in all that can work at from 12t/m to 251/m. Eight of them made their debut at last year's IAA commercial vehicle show in Hannover, Germany.

Features include the RCL 5300 overload protection package. "Combine it with our Electronic Vehicle Stability safety system and the user may further improve the loader's capacity by employing the load on the truck as a counterweight." says a company spokesman.

The newcomers are available with a stabiliser spread of 4.5m, 5.6m or 6.5m. HMF has come up with a range of loaders the 1244, 1444 and 1643-Z designed to handle scrap. The ability to fold them up behind a truck's cab while fitted with a clamshell bucket is an optional extra.

Devizes, Wiltshire-based TH White and Falkirkbased Outreach to distribute its products in the UK, Palfinger has made considerable changes to its portfolio over the past 18 months. New arrivals include 131/m to 181/rn single-link knuckle-boom loaders available with a 15-degree reverse-linkage knuckle-boom.

The 161/m capacity PK 16001 and the 18t/m capacity PK 18001-EH can both be equipped with up to six hydraulic boom extensions and boast a hydraulic outreach of 171m, Maximum stabiliser spread is 6.6m. Moving up the weight range, another new launch is the 39.3t/m PK 40002-EH. Useful features include a dual-slewing system, designed to reduce Mewing play to a minimum; an advantage if you are tackling a job that requires a high outreach.

It ensures a high stewing torque and precise crane movements, reveals Palfinger.

Also worthy of note is the crane's Dual Power System Plus package. It allows the fly jib to be operated safely with two pressure ranges through the use of an electronic overload protection device.

If the last extension boom on the crane is fully extended then lifting capacity will he reduced to prevent overloading, If it is retracted, however, then the system will automatically switch to high pressure, allowing the fly jib's maximum lifting capacity to be deployed.

New developments

Among PM's latest offerings are the double-linkage 15S and 16.5SP, both of which are available with up to six hydraulic extensions plus a range of accessories.

Distributed in the UK by Colchester, Essex-based company Ernest Doe, Cormach's loader line-up starts at 41/m and finishes at a mighty 1561/m.

Fresh introductions include a new 80t/rn model with a new 100t/m model due to debut in 2010.

All the loaders come with twin turrets and twin lift rams with continuous rotation on the bigger cranes. About 95% of them are sold complete with radio remotes, including the lighter models.

Rather less well-known in the UK than organisations such as Hiab is Effer, which has appointed well-known used truck exporter Britcom International as its dealer for the North.

Effer's line-up features the 305, which has a 27.39t/m capacity. The loader only requires a lm gap if it is to be mounted between the back of a truck's cab and the front of the body.

Other models include the 42/45. a 4t/m loader suitable for mounting on a 7.5-tonner. It features four hydraulic extensions for a total outreach of 9m and can handle weights of up to 1 ,030kg at a height of more than 9m.

Also worth a mention is the 145.11/2S. Sitting squarely in the 14t/m to 151/m sector, it has a knuckle-boom with a wide opening angle that allows the crane to lift tall loads inside buildings with low ceilings.

With a capacity of 12t/m and an outreach of up to 14.3m.Terex Atlas's best-selling model in the UK, the 120.2, is slightly lighter. However, the Terex Corporation can supply loaders that go up to 601/m alongside a selection of other equipment for the construction industry, including tower, lattice boom, and rough-terrain cranes.

Loader crane demand is unlikely to show sustained improvement before the middle of next year, Davies believes, and he would not be surprised to sec a few casualties in the industry between now and then.

"You can lose money forever. But you only run out of cash once," he muses.

"Hopefully, we'll see a recovery in 2010, but it's likely to he slow,says Sharratt. "And I'm worried that we might see a double-dip recession.18