'Jumbo' Sherpas are aiming for the top

Page 24

Page 25

Page 26

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

I description and driving wessions of the new le-bodied range. By Tim kemore IGHT ROVER's Sherpa range /ens and chassis cabs has n significantly extended with addition of wider and vier models having gross icle weights of 2.8, 3.1, and tonnes. The availability of se new models, designated i,310, and 350, is being sed in between now and the ng of 1984.

etrol-engined 285, 310, and short-wheelbase vans and g-wheelbase chassis cabs it on sale this week. It is ined to introduce diesel-ened models, long-wheelbase 1, and 350 vans, caravans iibuses, high-roof vans and ger-wheelbase chassis cabs, January 1984. These will be owed by 4x4 and ambulance sions of the new models.

he narrower, 2.3 to 2.8 tonnes gvw Sherpas, last revised in June last year, will continue to be made with some of the improved features of the heavier models being applied to them. One result of the new models' introduction is that Freight Rover can now offer both wide and narrow versions of its vans and chassis cabs at 2.8 tonnes gvw.

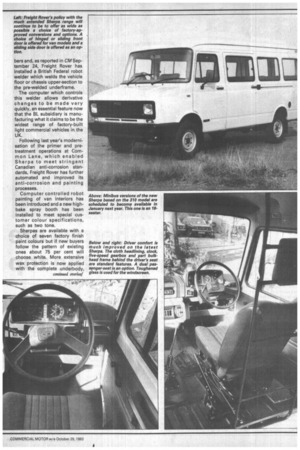

At 1,702mm (67in), the front track of the new Sherpa has been increased by 229mm (9in) while the rear track goes up from 1,416mm (55.75in) to 1,662mm (65.43in), 1,100mm (43.3in) on the 3.5 tonne model with twinned rear wheels.

Overall width of the wide van is 2,020mm (79.5in) compared with the narrow model's 1,710mm (67.3in) dimension while interior height of the standard height wide-bodied van (a high-roof model is available) is 1,460mm (57.5in) compared with the smaller Sherpa's 1,130mm (51.6in).

All Sherpas are being manufactured at Freight Rover's Common Lane plant in Birmingham where the production lines have been redesigned to give the flexibility required and to achieve minimum change-over time between derivatives.

Many parts, including B-post assembly, sliding side load door and front hinged door, are common to wide and narrow Sherpas, but despite extensive rationalisation Freight Rover's own press shop at Common Lane now has 250 more pressings to produce. New panels include the bonnet and rear doors.

The new van has the same side-wall panels, with vertical weld seams, as the old, but with revised cant rails and wider roof panel and floor pan. "Hypress" sheet steel, pressed to top-hat configuration, is now being used for chassis/underframe mem

bers and, as reported in CM September 24, Freight Rover has installed a British Federal robot welder which welds the vehicle floor or chassis upper-section to the pre-welded underframe.

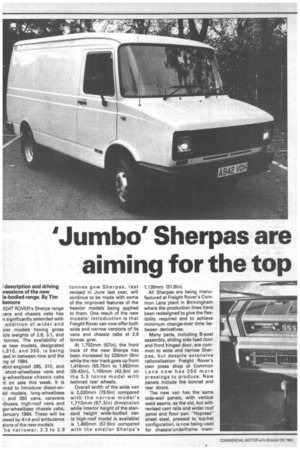

The computer which controls this welder allows derivative changes to be made very quickly, an essential feature now that the BL subsidiary is manufacturing what it claims to be the widest range of factory-built light commercial vehicles in the UK.

Following last year's moderni sation of the primer and pretreatment operations at Common Lane, which enabled Sherpa to meet stringent Canadian anti-corrosion standards, Freight Rover has further automated and improved its anti-corrosion and painting processes.

Computer controlled robot painting of van interiors has been introduced and a new highbake spray booth has been installed to meet special customer colour specifications, such as two tone.

Sherpas are available with a choice of seven factory finish paint colours but if new buyers follow the pattern of existing ones about 75 per cent will choose white. More extensive wax protection is now applied with the complete underbody,

J ding chassis, springs and

s receiving a coating. ;hanical details: All the tier petrol-engined Sherpas the two-litre 0 series ohc Ins which is fitted to some ting Sherpa and BL car leis. An lpgipetrol dual-fuel 'version by Solex Landi tog will be offered as a fac -approved option. The diesel me, which will become avail in January next year, is a eloped version of Land Royfour cylinder unit.

nother Land Rover compo t is the five-speed gearbox ch is fitted as standard to all new 2.8 to 3.5-tonne Sher . This single-helical, conit-mesh gearbox has synchesh on the top four gears. It le box currently fitted to Land er 110 and Range Rovers has an 0.83:1 overdrive top

he bottom four gear ratios e been slightly altered for the rpa application, to make -n more suitable for light

imercial work. The 285 and models have a 4.55 to 1 final ive ratio giving imph/1,000rpm in top gear, consequently a maximum red speed of around 87mph the petrol-engined models. he 350's 4.89 to 1 axle ratio Is to 18.1mph/1,000rprri and naximum speed of around Sherpa's tyres are 205 x 14 (sixply commercial on the 285 and eight-ply commercial on the 310) with single rear wheels while the 3.5-tonners have twinned rear wheels and 185 x 14 tyres.

All models use Freight Rover's own front beam axle with telescopic dampers, an anti-roll bar and single, tapered leaf springs. The rear axles with hypoid differentials are GKN Salisbury components, 15HA on 285 and 310 models, and 16HA on 350 models. Rear suspension is tapered single-leaf springs, the spring rate varying according to model, with telescopic dampers.

The servo-assisted hydraulic braking system operates 276mm (10.78in) diameter discs at the front and 254mm (10.00in) diameter drums with leading-andtrailing shoes at the rear.

One piece of innovation from which all current Sherpas are now benefiting is Freight Rover's energy absorbing bumpers. These no longer house any lights, and moreover are designed to withstand a 5km/h (3mph) impact without damage. The bumpers are made from RIM (resin injection moulded) plastic with a steel armature at the front and packed with polyurethane foam in vulnerable areas.