UK repair patent

Page 105

If you've noticed an error in this article please click here to report it so we can fix it.

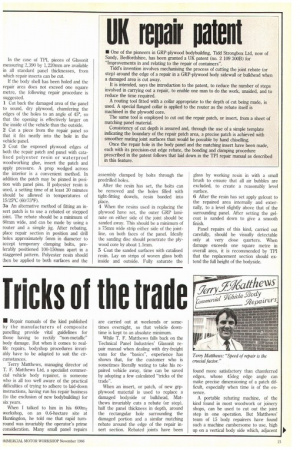

III One of the pioneers in GRP-plywood bodybuilding, Tidd Strongbox Ltd, now of Sandy, Bedfordshire, has been granted a UK patent (no. 2 109 300B) for "Improvements in and relating to the repair of containers".

Tidd's invention involves mechanising the process of cutting the joint rebate (or step) around the edge of a repair in a GRP-plywood body sidewall or bulkhead when a damaged area is cut away.

It is intended, says the introduction to the patent, to reduce the number of steps involved in carrying out a repair, to enable one man to do the work, unaided, and to reduce the time required.

A routing tool fitted with a collar appropriate to the depth of cut being made, is used. A special flanged collar is applied to the router as the rebate itself is machined in the plywood core.

The same tool is employed to cut out the repair patch, or insert, from a sheet of matching panel material.

Consistency of cut depth is assured and, through the use of a simple template indicating the boundary of the repair patch area, a precise patch is achieved with smoother mating joint surfaces than would be possible by hand chiselling.

Once the repair hole in the body panel and the matching insert have been made, each with its precision-cut edge rebate, the bonding and clamping procedure prescribed in the patent follows that laid down in the TPI repair manual as described in this feature.