Maximum Use Versus Overtime

Page 56

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

LAST week I discussed the cost of operating a 7-ton tipper for five, six or seven days per week, with one, two or three drivers. A reader had asked for advice on tendering for a four-year contract involving a 70-mile haul from quarry to site.

Particular attention was given to the problem of the Small haulier who did not possess and was unable to acquire the maximum-load vehicle that would prove ideal for this type of work. By maximum use of the popular 7-ton tipper, however, it was shown that costs per ton could be reduced by up to

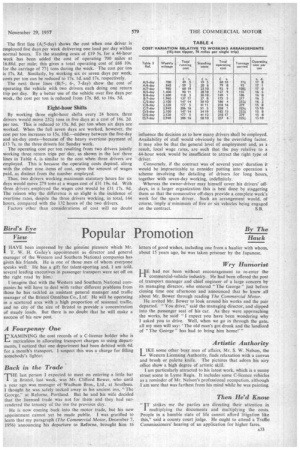

2s. 5d. This week the corresponding alternative working arrangements and costs of operating a maximum-load eightwheeled tipper under similar conditions are set *out in Tables 3 and 4.

Hopper Loading

As the inquirer stated that vehicles would be loaded by hopper at the quarry and tipped at,the site without delay, trip times should be virtually the same for both vehicles, so that a return run of 140 miles should also be accomplished by the larger vehicle during a normal day's work.

Table 3. shows variations of working arrangements made possible by the employment of one, two or three drivers working normal hours on five, six or. seven days per week, with each driver doing one return trip per shift. A fourth arrangement is shown in line D, -where 'two drivers complete three return trips within 24 hours by working the maximum statutory hours.

This could, however, be done only if suitable change-over arrangements for the drivers could be made, as each would then drive for three single trips and finish duty at the far terminal. Whether or not this is a feasible proposition, it cannot necessarily be assumed that the two drivers will, in fact, reside at either terminal point, particularly in these car-owning days. Weekly tonnages shown in Table 3 are based on an unladen weight of 8 tons 7 cwt. for the eight-wheeled rigid tipper, giving a legal payload of 151 tons.

Turning to the operating costs of this class of vehicle, the first item of standing costs is licence fees. The annual duty payable will be £140, plus a further £2 as the annual proportion of the A-licence fee, now £10 per five-year period. Allowing for two non-revenue-earning weeks each year, this would amount to 56s. 10d. per week.

Wages would be in the 15-18-ton category and, allowing for holidays with pay and national and employers' liability insurance contributions, would amount to £9 12s. 4d. per week. Rent and rates are assessed at 15s. per week and insurance at £3 per week. Interest is calculated at 3 per cent, on a capital outlay of £5,100.

The five items of standing coals thus total £19 5s. 4d. when the driving time is limited to 44 hours. The other arrangements shown in the tables, however, involve varying amounts of overtime which will all be chargeable to the one customer if the contract is secured. The cost of wages consequently ranges from £9 12s. 4d. per week when one driver is employed on a statutory week of 44 hours to £40 17s. 6d. when two drivers ea':h work 77 hours per week. Total standing costs have, therefore, been adjusted accordingly.

The largest of the five items of running costs is fuel, which is estimated to Cost 6.38d. per mile, based on a consumption rate of 8 m.p.g. Fuel economies obtainable during the long haul should compensate for consumption while tipping. Lubricant costs are assessed at 0.27d. per mile.

It is estimated that tyres will last for 40,000 miles. thereby costing 3d. per mile. Maintenance is calculated at 3.01d. per mile.

The depreciation cost of 4.22d. per mile is based on an estimated vehicle life of 250,000 miles and a residual value of £200. The five items of running costs total 16.88d. per mile.

In Table 4 the variations of working arrangements shown in Table 3 are combined with the appropriate running and standing costs to give the operating cost per week and per ton.

The first line (A/5-day) shows the cost when one driver is employed five days per week delivering one load per day within normal hours. To the standing costs of f19 5s. for a 44-hour week has been added the cost of operating 700 miles at 16.88d. per mile; this gives a total operating cost of £68 10s. for the carriage of 7'71 tons during the week. The cost per ton is 17s. 8d. Similarly, by working six or seven days per week, costs per ton can be reduced to 17s. Id. and 17s. respectively.

The next three lines •(B/5-, 6-, 7-day) show the cost of operating the vehicle with two drivers each doing one return trip per day. By a better use of the vehicle over five days per week, the cost per ton is reduced from 17s. 8d. to 16s. 5d.

Eight-hour Shifts

By working three eight-hour shifts every 24 hours, three drivers would move 2321 tons in five days at a cost of 16s. 2d. per ton. This is reduced to 15s. 8d. per ton when six days are worked. When the full seven days are worked, however, the cost per ton increases to 15s. 10d.—midway between the five-day and six-day costs—because of the heavy overtime payment of £13 7s, to the three drivers for Sunday work.

The operating cost per ton resulting from two drivers jointly working three return trips per day, as shown in the last three fines in Table 4, is similar to the cost when three drivers are employed. This is because the operating costs depend, along with the other nine items of cost, upon the amount of wages paid, as distinct from the number employed. Thus, two drivers working maximum statutory hours for six days would move 279 tons at a wages cost of £31 19s. 6d. With three drivers employed the wages cost would be £31 17s. 9d. The reason why the difference is so slight is the incidence of overtime rates, despite the three drivers working, in total, 144 hours, compared with the 132 hours of the two drivers.

Factors other than considerations of cost will no doubt

influence the decision as to how many drivers shall be employed. Availability of staff would obviously be the overriding factor. It may also be that the general level of employment and, as a result, local wage rates, are such that the pay relative to a 44-hour week would be insufficient to attract the right type of driver.

Conversely, if the contract was of several years' duration it would be impracticable to consider putting into operation a scheme involving the detailing of drivers for long hours, together with seven-day working, indefinitely. Whereas the owner-driver may himself cover his drivers' offdays, in a larger organization this is best done by staggering them so that the consecutive off-days provide a complete week's work for the spare driver. Such an arrangement would, of course, imply a minimum of five or six vehicles being engaged

on the contract. S.B.