Bodybuilders Form Own Brackets

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

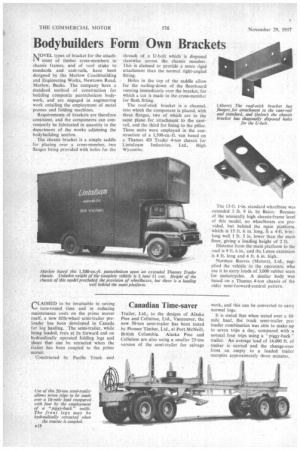

MOVEL types of bracket for the attach ment of timber cross-members to chassis frames, and of roof sticks to standards and cant-rails, have been designed by the Marlow Coachbuilding and Engineering Works, Newtown Road, Marlow, Bucks. The company have a standard method of construction for building composite pantechnicon bodywork, and are engaged in engineering work entailing the employment of metal presses and folding machines.

Requirements of brackets are therefore consistent, and the components can conveniently be fabricated in quantity in the department of the works adjoining the bodybuilding section.

The chassis bracket is a simple saddle for placing over a cross-member, two flanges being provided with holes for the

CLA1MED to be invaluable in saving turn-round time and in reducing maintenance costs on the prime mover itself, a new fifth-wheel semi-trailer preloader has been developed in Canada for log hauling. The semi-trailer, while being loaded, rests at its forward end on hydraulically operated folding legs and shoes that can be retracted when the trailer has been coupled to the prime mover.

Constructed by Pacific Truck and threads of a U-bolt which is disposed slantwise across the chassis member. This is claimed to provide a more rigid attachment than the normal right-angled fitting.

Holes in the top of the saddle allow for the nailing-down of the floorboard running immediately over the bracket, for which a Cut is made in the cross-member for flush fitting.

The roof-stick bracket is a channel, into which the component is placed, with three flanges, two of which arc in the same plane for attachment to the cantrail, and the third for fixing to the pillar. These units were employed in the construction of a 1,500-cu.-ft. van based on a Thames 4D Trader 4-ton chassis for Lintafoam Industries, Ltd., High Wycombe.

Trailer, Ltd., to the designs of Alaska Pine and Cellulose, Ltd., Vancouver, the new 50-ton semi-trailer has been tested by Pioneer Timber, Ltd., at Port McNeill, British Columbia. Alaska Pine and Cellulose are also using a smaller 25-ton version of the semi-trailer for salvage The 13-ft. 1-in, standard wheelbase was extended 3 ft. 9 in. by Baico. Because of the unusually high chassis-frame level of this model, no wheelboxes arc provided, but behind the main platform. which is 15 ft. 6 in. long, is a 4-ft. 6-in.long well 1 ft. 3 in. lower than the main floor, giving a loading height of 2 ft.

Distance from the main platform to the roof is 9 ft. 6 in.. and the Luton extension is 4 ft. long and 4 ft. 6 in. high.

Norman Reeves (Motors), Ltd., supplied the vehicle to thc operators, who use it to carry loads of 3,000 rubber scats for motorcycles. A similar body was based on a Thames 4-ton chassis of the older semi-forward-control pattern.

work, and this can be converted to carry normal logs.

It is stated that when tested over a 10mile haul, the truck semi-trailer preloader combination was able to make up to seven trips a day, compared with a normal four trips using a "piggy-back" trailer. An average load of 14,000 ft. of timber is carried and the change-over from an empty to a loaded trailer occupies approximately three minutes.