It's TURN-ROUND TIME That Counts

Page 42

Page 43

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

By Alan Smith, F.R.S.A.

How Aspro Nicholas Have Evolved a Successful Means for Loading Vans by Fork-Lift Truck : Scrapping of 20-m.p.h. Limit Ends Many Problems

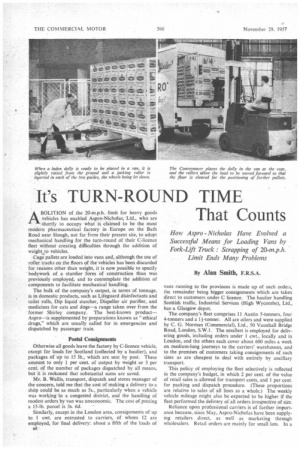

ABOLITION of the 20-m.p.h. limit for heavy goods vehicles has enabled Aspro-Nicholas, Ltd., who are shortly to occupy what is claimed to be the most modern pharmaceutical factory in Europe on the Bath Road near Slough, not far from their present site, to adopt mechanical handling for the turn-round of their C-licence fleet without creating difficulties through the addition of weight, to vehicles.

Cage pallets are loaded into vans and, although the use of roller tracks on the floors of the vehicles has been discarded for reasons other than weight, it is now possible to specify bodywork of a sturdier form of construction than was previously employed, and to contemplate the addition of components to facilitate mechanical handling.

The bulk of the company's output, in terms of tonnage, is in domestic products, such as Lifeguard disinfectants and toilet rolls, Dip liquid starcher, Dispeller air purifier, and medicines for cats and dogs—a range taken over from the former Shirley company. The best-known productAspro—is supplemented by preparations known as "ethical drugs," which are usually called for in emergencies and dispatched by passenger train.

Postal Consignments

Otherwise all goods leave the factory by C-licence vehicle, except for loads for Scotland (collected by a haulier), and packages of up to 15 lb., which are sent by post. These amount to only 1 per cent. of output by weight or 3 per cent. of the number of packages dispatched by all means, but it is reckoned that substantial sums are saved.

Mr. B. Wallis, transport, dispatch and stores manager of the concern, told me that the cost of making a delivery to a shop could be as much as 5s., particularly when a vehicle was working in a congested district, and the handling of modest orders by van was uneconomic. The cost of posting a 15-lb. parcel is 3s. 6d.

Similarly, except in the London area, consignments of up to 1 cwt. are entrusted to carriers, of whom 12 arc employed, for final delivery: about a fifth of the loads of B8 vans running to the provinces is made up of such ordets, the remainder being bigger consignments which are taken direct to customers under C licence. The haulier handling Scottish traffic, Industrial Services (High Wycombe), Ltd., has a Glasgow depot.

The company's fleet comprises 11 Austin 5-tonners, four 4-tonners and a 11-tonner. All are oilers and were supplied by C. G. Norman (Commercial), Ltd., 50 Vauxhall Bridge Road, London, S.W.1. The smallest is employed for delivering goods, including orders under 1 cwt., locally and in London, and the others each cover about 600 miles a week on medium-long journeys to the carriers' warehouses, and to the premises of customers taking consignments of such sizes as are cheapest to deal with entirely by ancillary transport.

This policy of employing the fleet selectively is reflected in the company's budget, in which 2 per cent. of the value of retail sales is allowed for transport costs, and 1 per cent. for packing and dispatch procedure. (These proportions are relative to sales of all lines as a whole.) The weekly vehicle mileage might also be expected to be higher if the fleet performed the delivery of all orders irrespective of size.

Reliance upon professional carriers is of further importance because, since May, Aspro-Nicholas have been supplying retailers direct, as well as marketing through wholesalers. Retail orders are mainly for small lots. In a week, about 200 tons of goods leave the factory, representing 2,500 consignments totalling 35,400-40,000 packages. There is little fluctuation in the volume of traffic, except that demand for-.disinfectant and liquid starcher rises during the summer and autumn.

Documentary procedure preceding vehicle loading begins with the receipt by the dispatch department of invoices corresponding to customers' orders. These are sorted into 36 pigeon-holes representing different areas of the country and systems of delivery—either direct by C-licence transport or thrbugh .a carrier. It is the policy that no invoice should he held in the office for more than three days.

Invoices are next made up into loads for vehicles, these being drawn up on quadruplicated movement sheets, of which 30-40 may be compiled in a day. The top copy is for the packers, the second and third for the carrier (where appropriate), and the fourth is an account copy for sales control. One of the two sheets made out for the carrier is ruled as an invoice, for return to• Aspro-Nicholas for payment.

This saves the carrier -making out his own bill: all that he needs to do is put.down his charges against the various consignments. These standard invoices are also easier for the company to check.

Summary totals are made of the different amounts of each product required and requisitions are made from stock, the production planning control department being informed at this stage so that replacement output can be arranged. A feature of the company's economy is nightly stock-taking, physical stocks being checked against the book figures of the production .planning control department.

This is regarded as good housekeeping, and proved of particular value when, earlier this year, the Lifeguard fac tory at Heywood, Lanes, was being closed down and stocks had to be run down day by day to nil. 11

Work is also facilitated by the use of a code for the different lines. Labelling, except for Aspro and veterinary medicines, is eliminated, as code numbers are printed on cartons. Delivery notes contain columns of code figures representing various products, other columns indicating quantities and number of deliveries.

Before the company began to use cage pallets (known as dollies), flat wooden pallets were in use (and still are for storage) for the transport of products from the Heywood factory to Slough for distribution. These pallets are 5 ft. long and 3 ft. 4 in. wide, and when it was decided to introduce cage pallets these were made 6 ft. 8 in. wide so that, if necessary, wooden pallets could be carried side by side in the cages.

The dollies, which are 5 ft. long, arc collapsible so that they need occupy little space when being carried as empties. The platform is supported on a plinth 74 in. deep with apertures for the entry of forks, and at each corner is a 4-ft. 6-in, removable pillar. The 3-ton limit, in force when these pallets were being initially tried out, necessitated the sides of vehicles being thinly skinned, and the original intention of using wire around the pillars of the dollies was to support the weight of the loads, thereby relieving the sides of the vans of stress.

Although this consideration no longer holds, and the sides of the vans are now stronger, wire caging is still employed to contain leads on the pallets during loading. Three pallets may be placed in a vehicle, and the loads. on the rearmost two are built up to provide a central aisle.. All vans have central translucent roof panels.

.Wire caging is removed from those sides of the pallets where it Would impede the driver's access to the load. Stay bars are fixed across the tops of the pallets. When bulk loads are being carried, pallets are fully laden and extra cartons may be placed on. the top up to the roof.

Side loading had been considered impracticable, because the provision of roller shutters along the full length of one side of the body would have brought the unladen weight of the vehicle over 3 tons, and a rear entry would have to be provided for access to the load on each side of the aisle. Consequently, thought was given to making end-loading convenient.

The first vehicle was fitted with three sets of rollers upon which the pallets could be moved forwards. The disadvantage of this arrangement, however, was that goods tended to shift and buffet the ends of the vehicle, not resting on is floor in the normal manner. Payload capacity was also reduced.

The next idea was to use the rollers as separate equipment, placing them inside the vans for loading and jacking them out from under the pallets and removing them after loading. As each line a rollers weighed 6 cwt., this practice was cumbersome, but the development from it has proved successful.

This entails the use of jacking rollers, made up in the company's own engineering shop. Not too heavy for a man to lift, each unit consists of a narrow frame with a pair of small wheels at the ends. Down the middle of the frame runs a long screw with a nut at each end. When a nut is turned, two levers are caused to rise.

The tops of these levers have flanges which fit into two guides underneath the dollies. When a pallet is to be placed in a van, the rollers are first inserted in the guides and the pallet is raised slightly from the ground to take the weight off the rollers. This makes it easier to turn the nuts to elevate the levers than were this done when the pallet was resting on the ground.

This Austin .11-ton oiler is employed for deliveries in the area around Slough. Effective use is made of the panelling for publicity purposes.

Early Departure

The dolly is then run into the van and the rollers are withdrawn after the levers are wound down. By this means, a 5-ton vehicle can be loaded in 13 minutes, whereas by hand methods three men would require an hour. Palletloads are made up in normal working hours and checked preparatory to loading vehicles for early-morning departure. A further improvement to be effected is the placing of steel plates on the floors of the vehicles,, upon which the wheels of the roller units may run. This is another development which could not have been entertained if a 3-ton limit prevailed. A Conveyancer 6,000-lb. battery-electric fork-lift truck is employed to load vans. The width of the vehicles' interior space exceeds that of the pallets by 2 in. and a 6-in, sideshift attachment enables the pallets to be accurately placed. Six other Conveyancer battery-electrics are tiled around the works.

The fork-lift truck has, of course, made the loading bank out of date, and in the case of Aspro-Nicholas this is doubly fortuitous, because the loading bay of their new factory cannot be provided with a bank. If the works are ever extended, which seems likely, the loading bay would have to be shifted. The bay measures 20 ycL by 40 yd. and there is 20-ft. roof clearance.

Driver's Assistance

Maintenance routines are performed at 1,500and 3,000mile intervals, drivers assisting fitters in this work to gain familiarity with their vehicles. The one-driver, one-vehicle principle is followed.

Drivers' wages are good and a meal allowance is paid. The company seek to employ men who will be suitable representatives of the concern, an aspect which has become more important since direct distribution to retailers has been started. Aspro-Nicholas belong to the commercial section of the Automobile Association, and the drivers have joined the B.M.C. Drivers' Club.

The fuel-consumption rate of the 34-litre 4-tonners at between 17.2 m.p.g. and 19.4 m.p.g. compares with 17.619.6 m.p.g. for the 5.1-litre 5-tonners, and the larger outfits are to be increased in number. Purchase of the 4-tonners was justified only in the days of the 20-m.p.h. limit.

Its abolition has provided for Aspro-Nicholas a clear field for development in increasing transport efficiency, not by raising the distances that can be covered each day by attaining a higher average road speed, but by cutting turnround times.